EBG surface-loaded millimeter wave SIW horn antenna

A horn antenna and millimeter-wave technology, applied in waveguide horns, antenna arrays that are energized separately, antennas, etc., can solve problems such as difficult matching, low gain, and poor matching performance of dielectric substrates, and achieve high antenna gain, improved gain, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An embodiment of the present invention is a millimeter-wave SIW horn antenna loaded on the surface of an EBG.

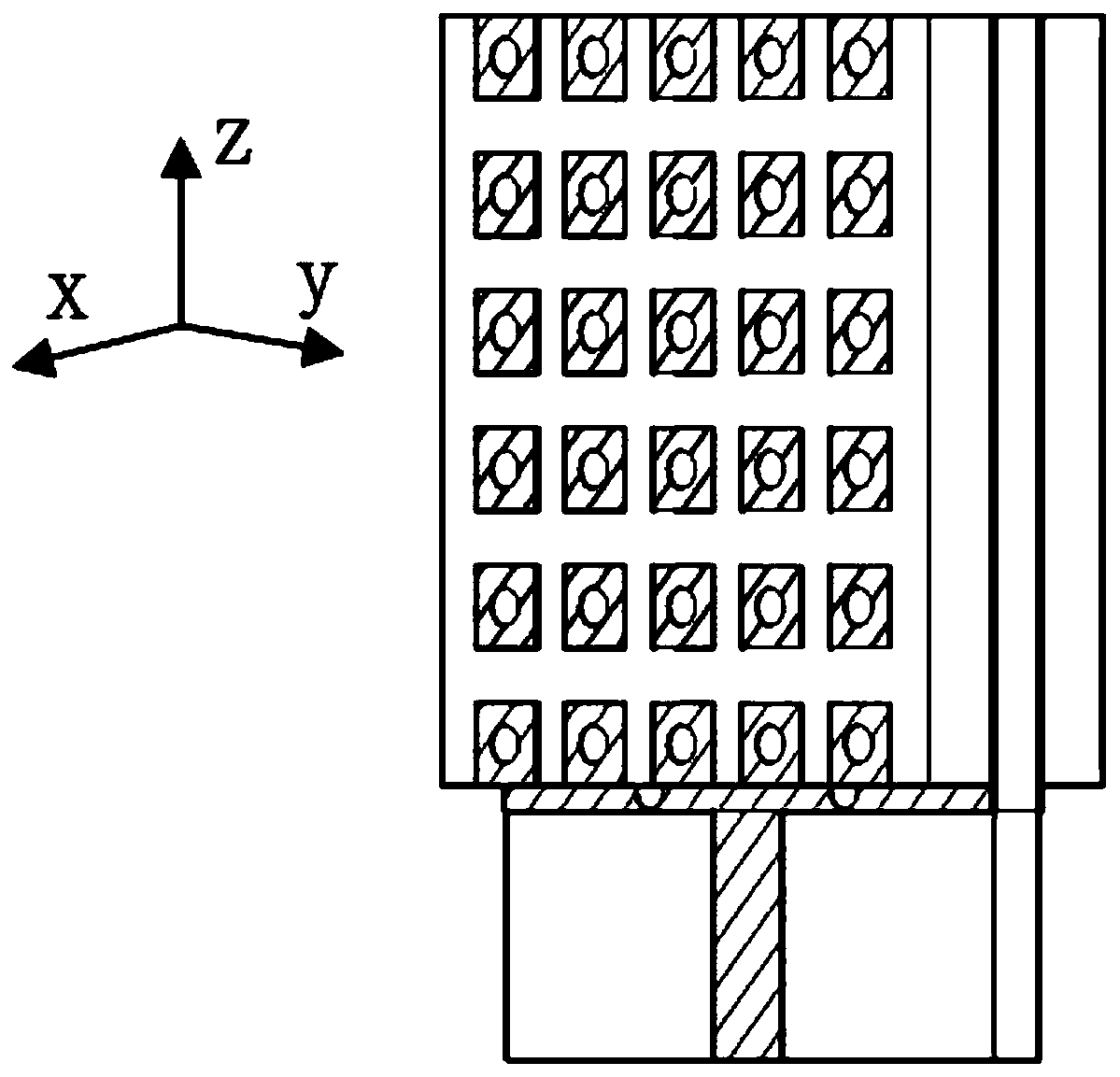

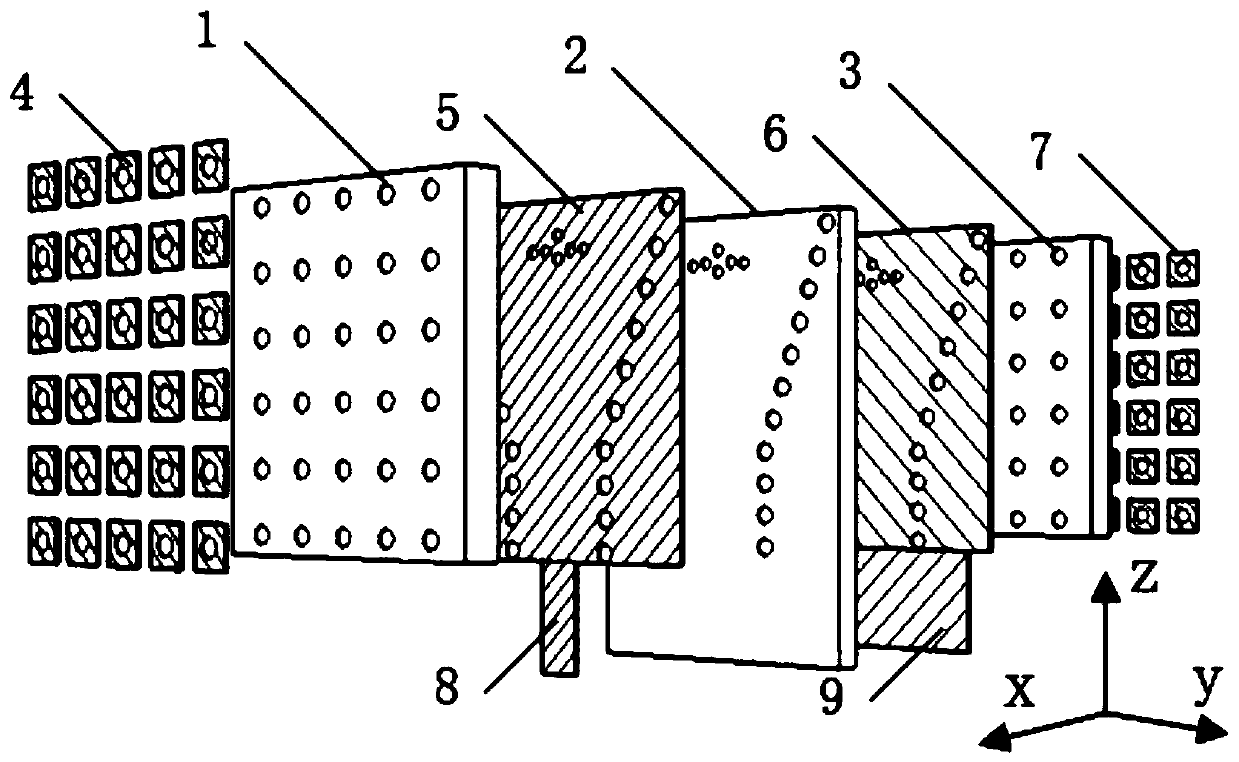

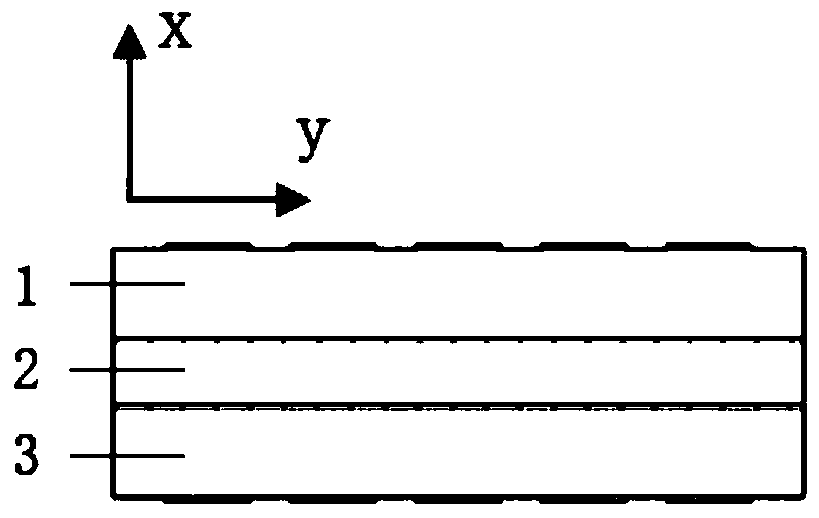

[0033] Such as Figure 1 ~ Figure 4 As shown, the millimeter-wave SIW horn antenna loaded on the EBG surface of this embodiment includes: an upper EBG layer metal plate 4, an upper EBG layer dielectric substrate 1, an upper radiation layer metal plate 5, and a radiation layer dielectric substrate 2 pressed together in sequence. , the lower radiation layer metal plate 6 , the lower EBG layer dielectric substrate 3 and the lower EBG layer metal plate 7 . The metal plate 8 of the feed layer is coplanarly interconnected with the metal plate 5 of the upper radiation layer, and the metal ground 9 of the feed layer is interconnected with the metal plate 6 of the lower radiation layer. The upper EBG layer dielectric substrate 1, the radiation layer dielectric substrate 2, and the lower EBG layer dielectric substrate 3 are all made of LTCC (Low Temperature Co-fired Ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com