Bridgeless buck-boost AC-to-DC converter

A DC converter, buck-boost technology, applied in the direction of converting AC power input to DC power output, irreversible AC power input conversion to DC power output, high-efficiency power electronic conversion, etc., can solve high output voltage, high cost, The number of components is too large to achieve the effect of improving the conversion efficiency and avoiding the sound of the power-on relay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

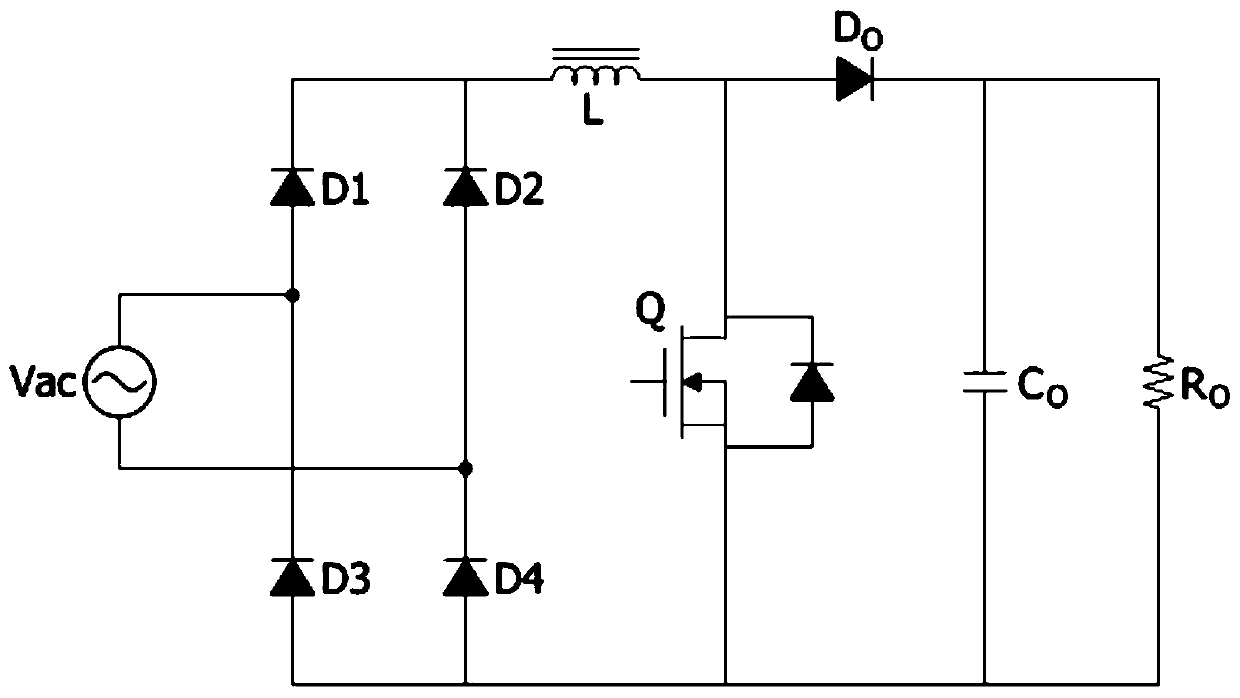

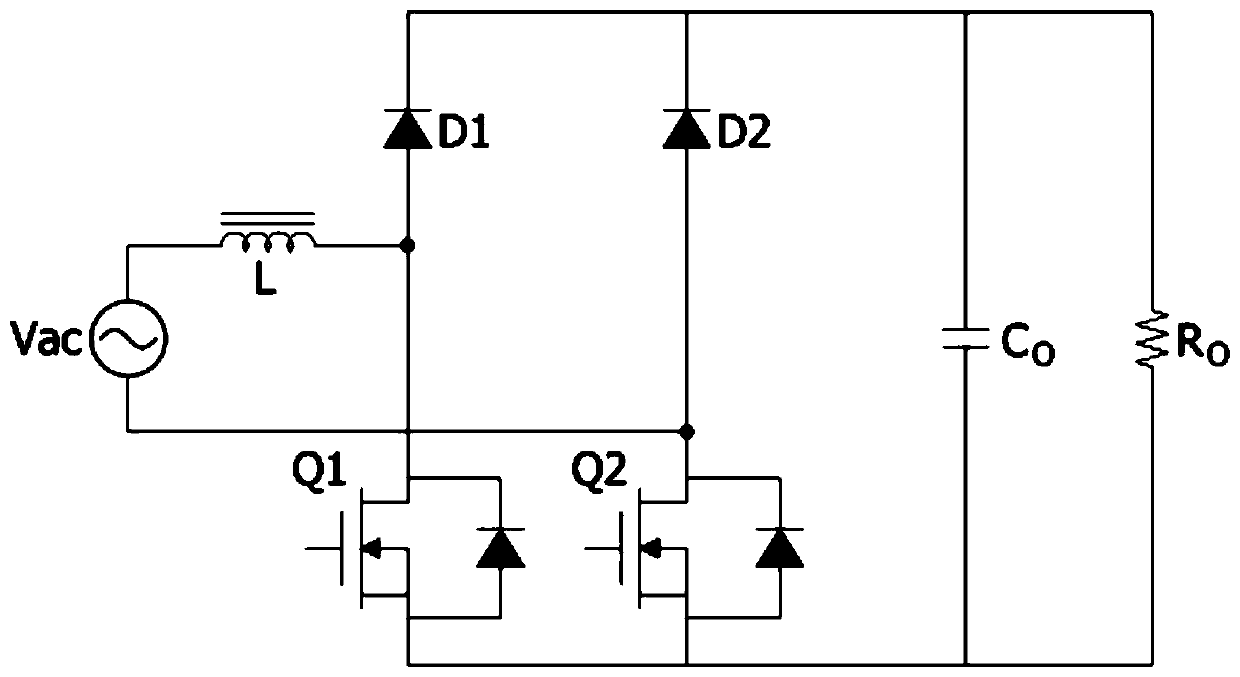

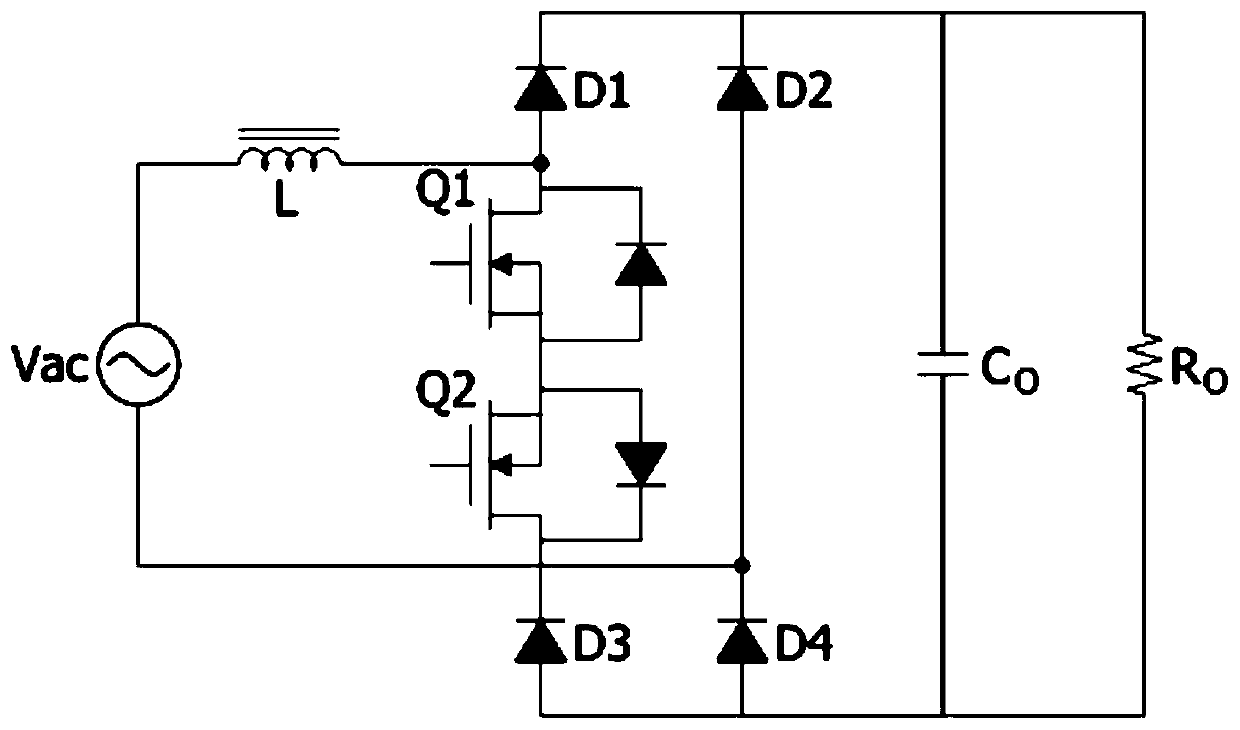

[0036] Specific embodiment one: please refer to Figure 9 As shown, the bridgeless buck-boost AC-to-DC converter is used to convert an AC input power Vac, and then provide a DC output power Vo with a positive terminal and a negative terminal on the output capacitor Co. The bridgeless buck-boost AC-DC converter includes a first circuit 10 , a second circuit 20 , a third diode D3 and a fourth diode D4 .

[0037] The first line 10 has a first end, a second end and a third end. The first terminal is coupled to the first terminal of the AC input power Vac, the second terminal is coupled to the ground terminal, and the third terminal is coupled to the positive terminal or the negative terminal of the DC output power Vo. The second line 20 has a first end, a second end and a third end, the first end is coupled to the second end of the AC input power supply Vac, the second end is coupled to the ground end, and the third end is coupled to The positive terminal or the negative termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com