Funnel type smoke dust filtering device

A dust filtration, funnel-type technology, applied in the direction of dispersed particle filtration, separation method, dispersed particle separation, etc., can solve the problems of adjusting the size of the dust filter pores, increasing the pressure difference of the flue gas dust filter device, and not being able to effectively filter dust particles and impurities , to achieve the effect of increasing the reserved time and improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

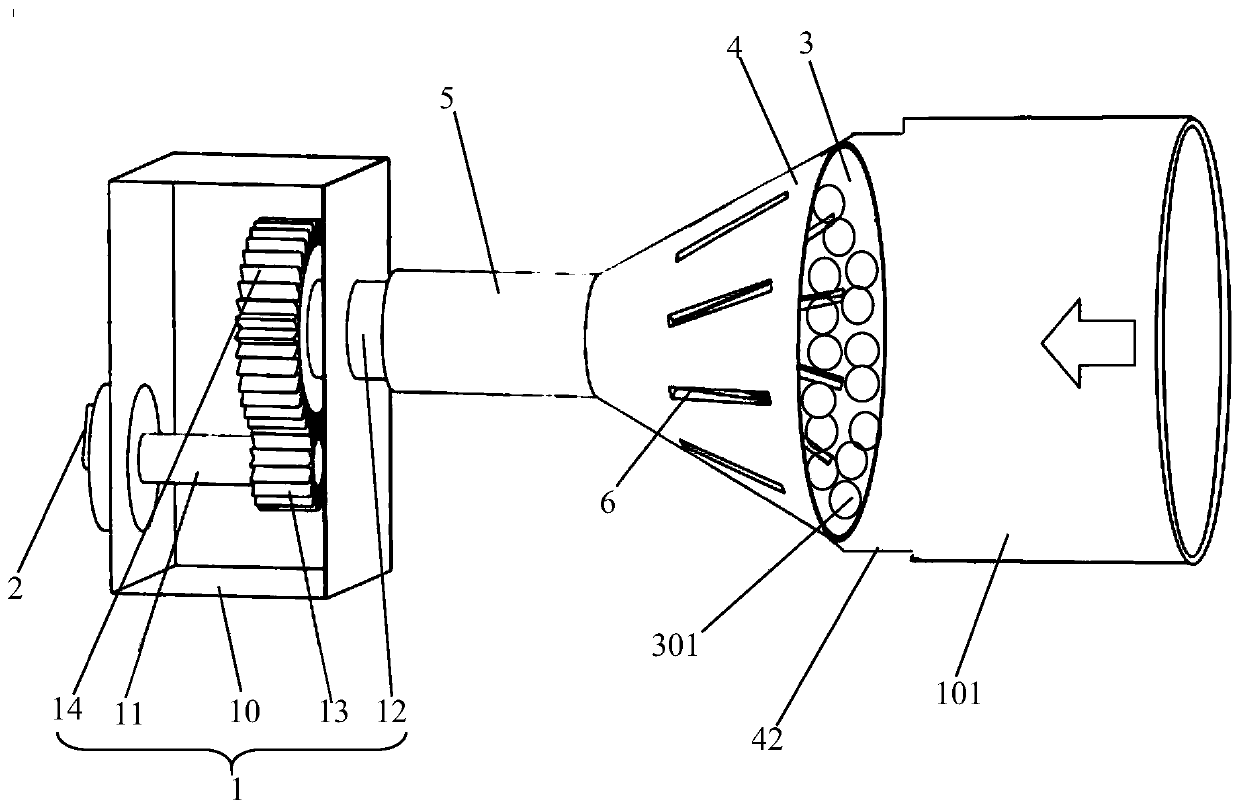

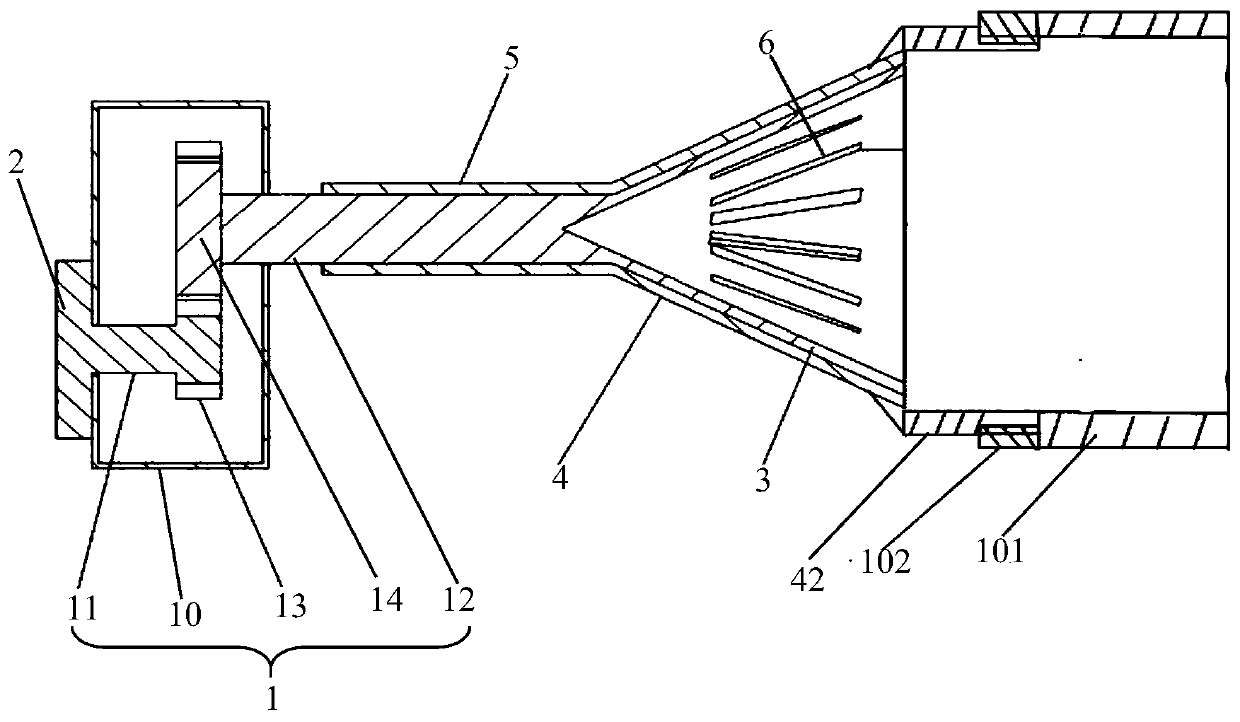

[0061] The embodiment of the present invention discloses a funnel-type flue gas dust filter device, the working principle is as follows:

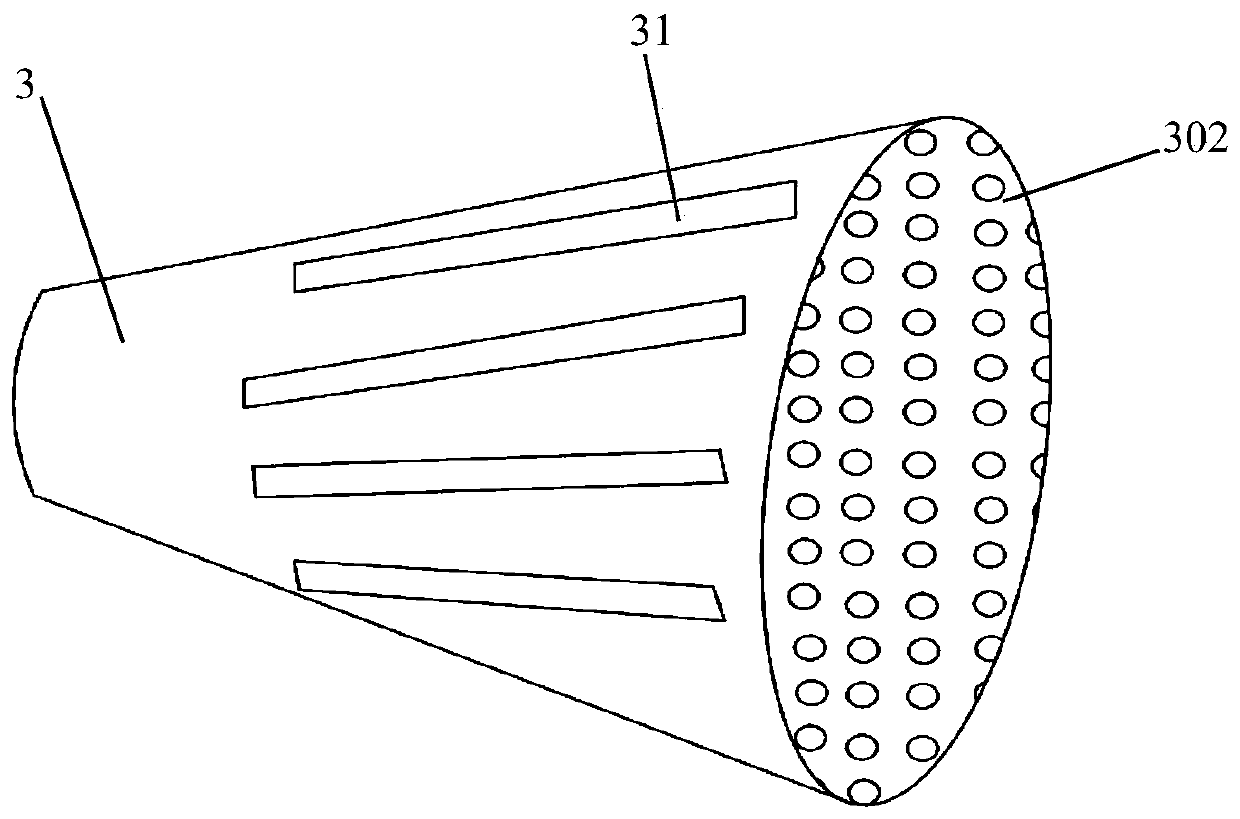

[0062] The cylindrical cylinder 42 of the present invention is connected to the exhaust pipe 101, and the smoke flows from the exhaust pipe 101 to the filter funnel 3, and the scale turntable 2 is rotated so that the scale turntable 2 drives the input shaft 11 to rotate, thereby making the first cylindrical gear 13 is meshed with the second cylindrical gear 14 for transmission, so that the input shaft 11 drives the output shaft 12 to rotate through the gear transmission mode, and then the output shaft 12 drives the inner filter funnel 3 to rotate, and the outer filter funnel 4 of the present invention is connected to the exhaust pipe 101 keep still, so the present invention can control the position of the inner filter funnel 3 relative to the outer filter funnel 4 through the scale dial 2, thereby changing the position between the first filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com