Portable cable flaw detection robot system

A robot system and portable technology, applied in radio wave measurement systems, instruments, manipulators, etc., can solve the problems of undiscovered cable fault detection applications, local temperature rise insensitivity, and large laying investment, so as to save manpower and material resources and ensure power supply Reliability and operation cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The portable cable flaw detection robot system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

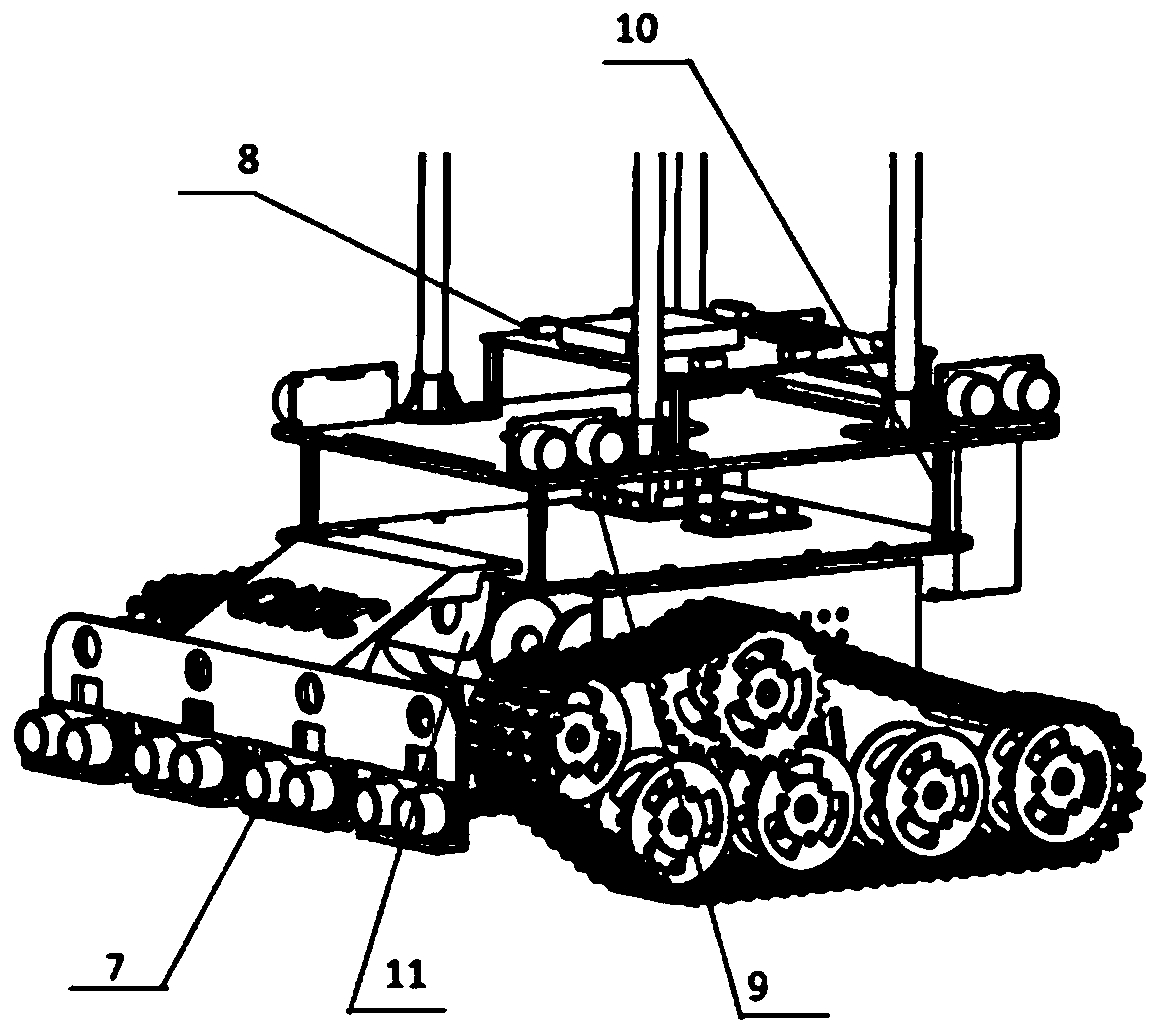

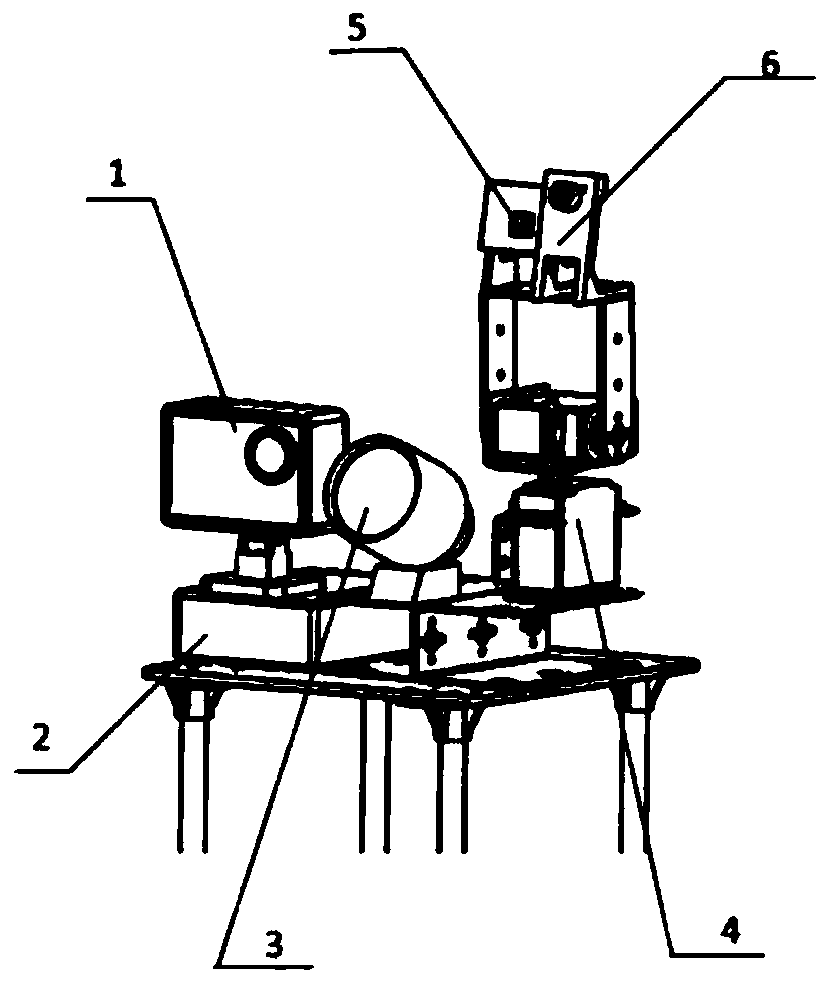

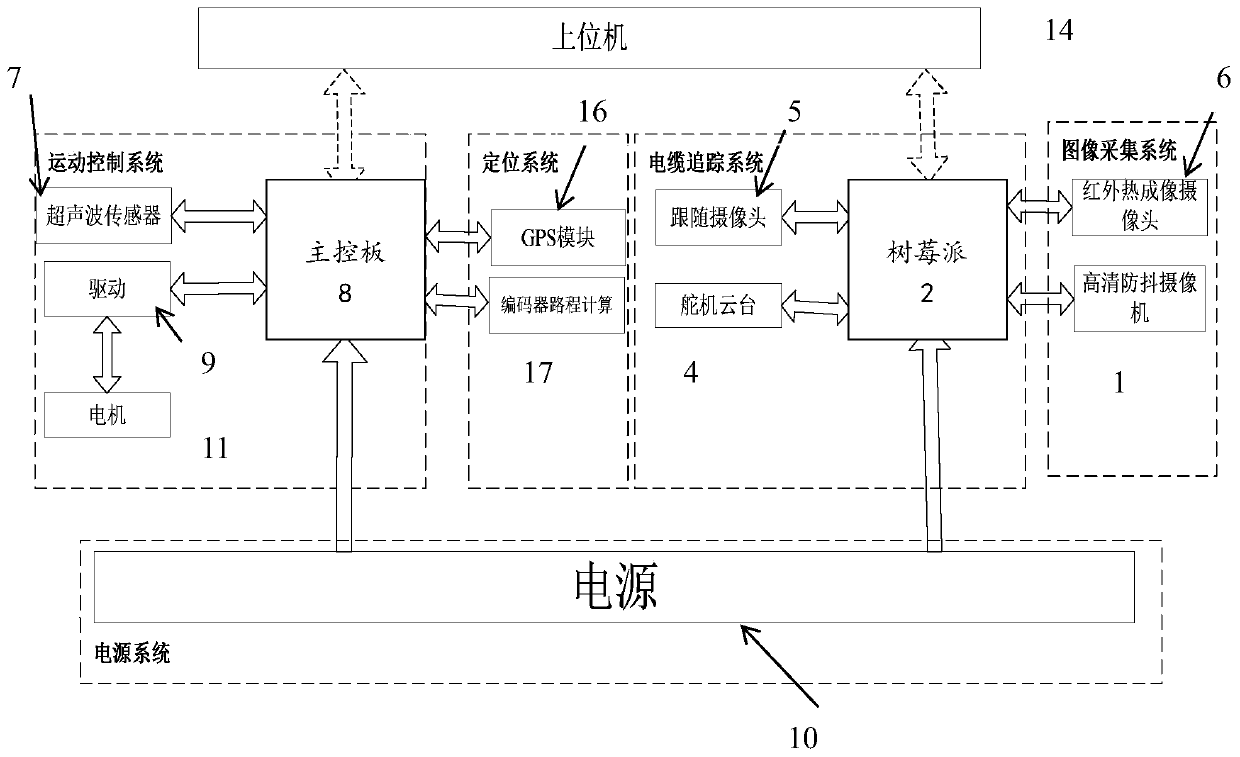

[0017] Such as Figure 1-Figure 3 As shown, the portable cable flaw detection robot system provided by the present invention includes a high-definition anti-shake camera 1, a raspberry pie 2, an LED light 3, a steering gear pan / tilt 4, a following camera 5, an infrared thermal imaging camera 6, an ultrasonic sensor 7, a main controller Plate 8, motor drive plate 9, power supply 10, motor 11, car body 12, support platform 13, GPS module 16 and distance calculation module 17; Wherein car body 12 adopts crawler structure; The lower end of support platform 13 is fixed on car body 12 edge of the top surface; HD anti-shake camera 1, raspberry pie 2, LED light 3 and steering gear pan / tilt 4 are installed on the top surface of support platform 13; following camera 5 and infrared thermal imagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com