Water pipe winding device for garden watering

A sprinkler and water pipe technology, applied in the field of gardens, can solve the problems of water pipe surface corrosion, pollution without effective cleaning, and the impact of water pipe service life, etc., to achieve the effect of increasing the contact area, preventing damage, and preventing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

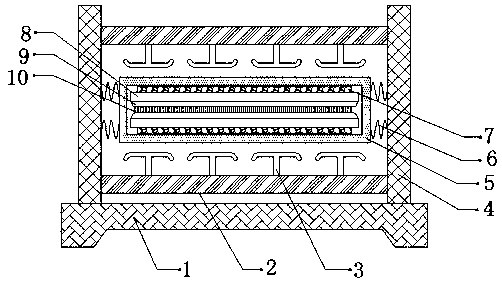

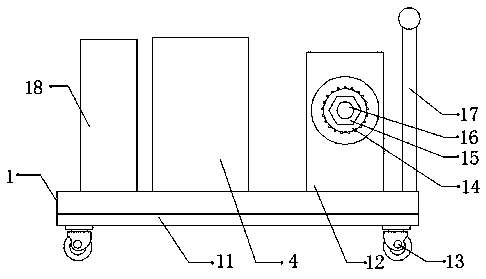

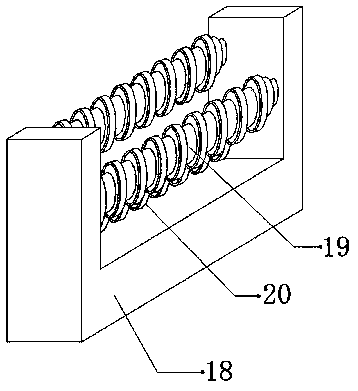

[0028] refer to Figure 1-3 , a garden sprinkling water hose winding device, including a fixed seat 1, one side of the top outer wall of the fixed seat 1 is connected with two connecting plates 4 by bolts, and the outer walls of the opposite side of the two connecting plates 4 are connected by bolts Spring 6, and one side outer wall of spring 6 is connected with support seat 5 by bolt, and one side outer wall of support seat 5 is provided with cleaning mouth, and the top outer wall and the bottom inner wall of cleaning mouth are all bonded with extruding block 7, two The outer walls of the opposite side of the extrusion block 7 are all connected with support plates 8 by bolts, and the outer walls of the opposite sides of the two support plates 8 are provided with fixing grooves, and the inner walls of the two fixing grooves are rotatably connected with rotating rollers 9, and The outer wall of the rotating roller 9 is provided with a cleaning brush 10, two fixed plates 2 are c...

Embodiment 2

[0038] refer to Figure 4 , a garden sprinkling water pipe rewinding device. Compared with Embodiment 1, this embodiment has a side plate 21 connected to one side of the top outer wall of the fixing seat 1 by bolts, and a fixed opening is opened on one side of the outer wall of the side plate 21. And the inner wall of the fixed port is connected with a dryer 22 by bolts.

[0039] Working principle: When in use, wrap one end of the water pipe to be wound on the winding roller 14 through the support rod 19 and the cleaning port, start the motor, and the motor will drive the winding roller 14 to rotate, thereby winding the water pipe. During this period, the water pipe can be squeezed by the extrusion block 7, so as to deal with the dirt adhering to the water pipe, and prevent the dirt from corroding the water pipe. range, so as to make the collision between the support seat 5 and the impact plate 3, so as to clean up the larger impurities adhered to the surface of the water pipe....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com