Chemical fiber drawing equipment for textile production

A chemical fiber and equipment technology, applied in the field of chemical fiber spinning equipment for textile production, can solve the problems of poor tension effect affecting storage neatness, inconvenient disassembly and replacement of storage structure, lack of guiding and cleaning functions, etc., to achieve improved spinning effect, guarantee the effect of spinning, and improve the efficiency of spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

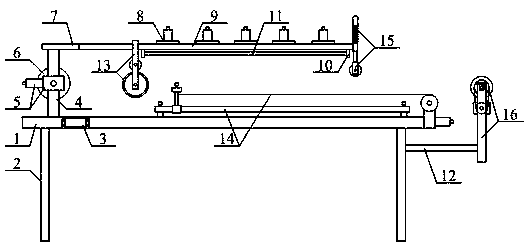

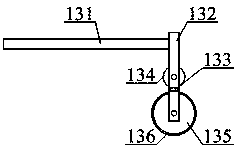

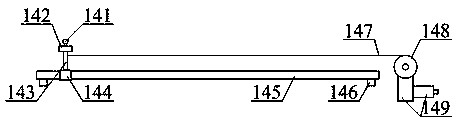

[0037]The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the chemical fiber spinning equipment for textile production includes frame 1, machine legs 2, control machine 3, machine base 4, fiber release motor 5, fiber release wheel 6, beam 7, heat dissipation fan 8, heat dissipation frame 9, Tube base 10, cooling tube 11, connecting seat 12, heatable fiber spinning guide cleaning wheel structure 13, fast spinning traction moving machine structure 14, bufferable tensioning guide conveying wheel structure 15 and detachable spinning rear The replacement wheel structure 16 is accommodated, and the four corners of the bottom of the frame 1 are longitudinally bolted to the organic legs 2; the front left side of the frame 1 is screwed to the control machine 3; The side longitudinal bolts are connected to the organic base 4; the front middle position of the base 4 is bolted to a fiber releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com