System and method for controlling variable-frequency washing machine based on direct-current brushless motor drive

A brushless DC motor and control system technology, applied in the direction of motor control, washing machine control device, control system, etc., can solve the problem of low control accuracy of frequency conversion washing machine, improve safety and reliability, improve accuracy and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

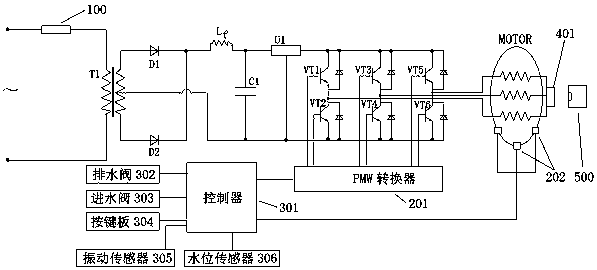

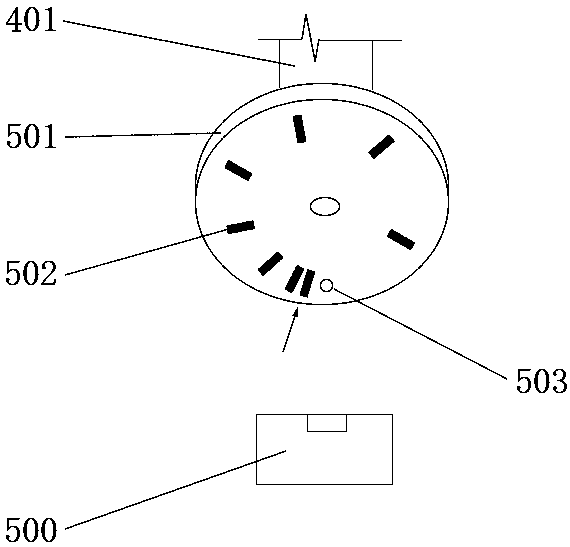

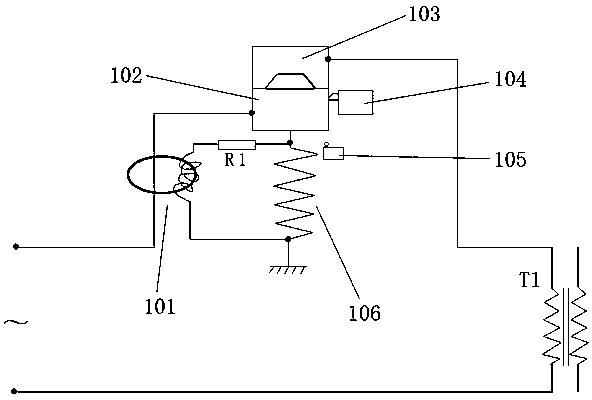

[0024] A control system based on DC brushless motor driven frequency conversion washing machine, such as figure 1As shown, this embodiment includes a transformer T1, a rectifier, a voltage stabilizer, a converter, a water level sensor 306, a water inlet valve 303, a drain valve 302, a keypad 304, a vibration sensor 305, a brushless DC motor rotor 401 positioning unit and The controller 301, the transformer T1, the rectifier, the voltage stabilizer and the converter are connected in sequence, the primary coil of the transformer T1 is connected to the mains, and the mains is transformed by the transformer T1 and then converted into direct current by the rectifier and input after being regulated by the voltage stabilizer To the converter, the three windings of the DC brushless motor are connected to the converter, the three Hall sensors 202 of the DC brushless motor are connected to the controller 301, and the controller 301 controls the DC brushless motor according to the preset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com