Single-class and multi-class tiny object suspension directional movement and self-loading huge transfer method

A technology of directional movement and transfer method, which is applied in the directions of microstructure devices, processing microstructure devices, assembling microstructure devices, etc., which can solve the problems of low transfer efficiency, poor positioning accuracy, and poor operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

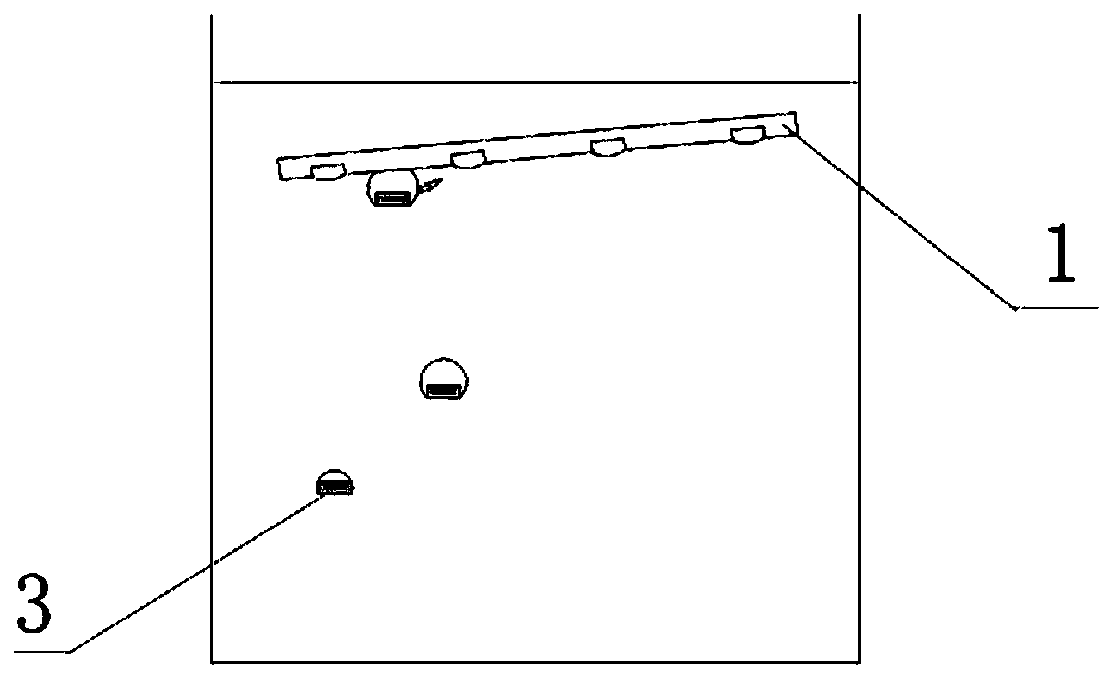

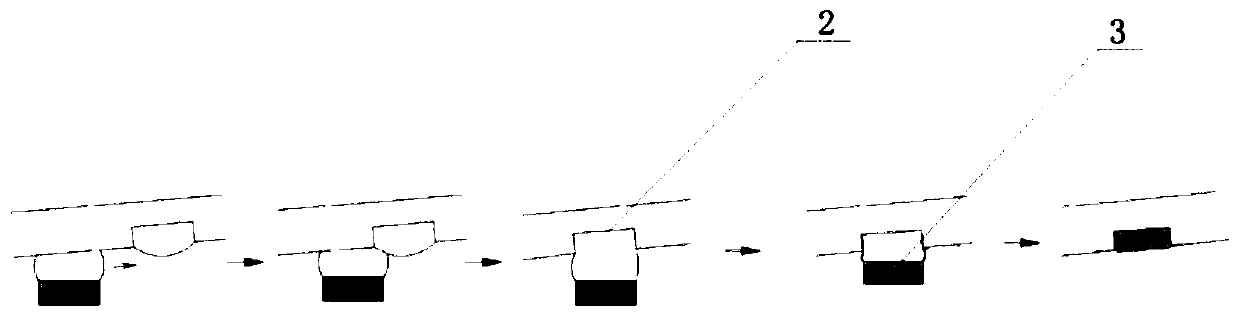

[0048] Figure 1 to Figure 2 Shown is the first embodiment of the method for floating directional movement of a single type of small objects and autonomously mounted massive transfer of the present invention. The method of suspending and directional movement of a single class of small objects and autonomously mounted massive transfer includes the following steps:

[0049] S1. After surface treatment of the small objects 3 to be transferred, they are put into solution A with surfactant and viscosity modifier. The surface of the small objects 3 does not infiltrate with the solution A, and the density of the solution A is lower than that of the small objects 3;

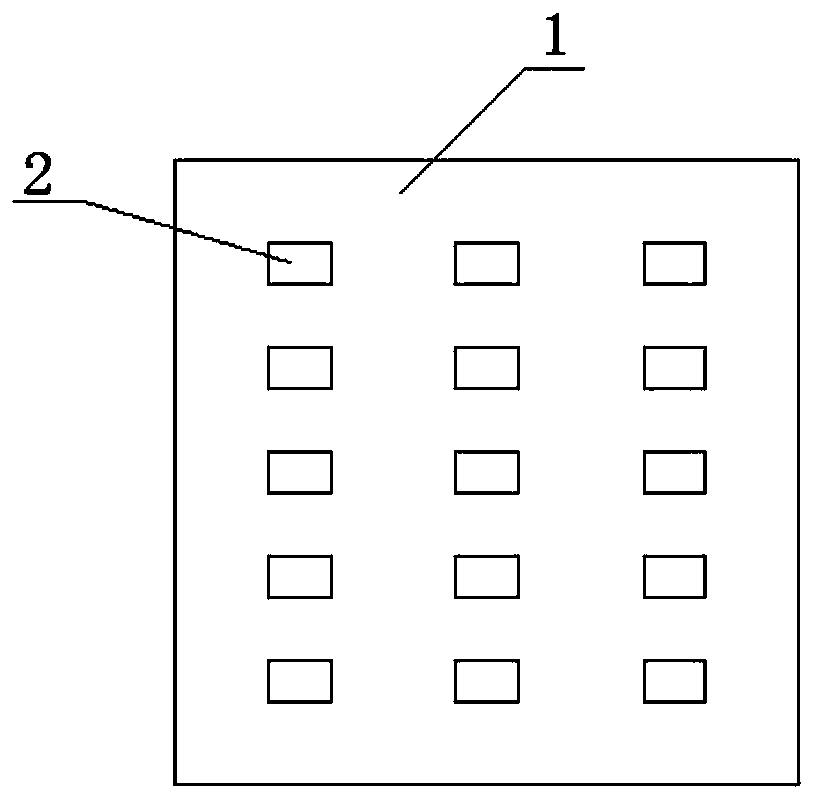

[0050] S2. Perform patterning treatment and surface treatment on the target carrier 1 so that a patterned groove 2 is generated at the target position, and the surface of the patterned groove 2 does not infiltrate the solution A but wets the surface of the small object 3, and the target carrier The surface of the board 1 exc...

no. 2 example

[0060] This embodiment is an embodiment of the method of floating and directional movement of multiple types of small objects and autonomously mounted mass transfer methods. The difference from the first embodiment is that in this embodiment, three different shapes of small objects are realized on a target carrier. The method of suspending and directional movement of objects and autonomous transfer of massive amounts. The numbers of the three types of small objects with different shapes and sizes are the first small object 7, the second small object 8, and the third small object 9, respectively.

[0061] The patterned grooves of three shapes and sizes are produced on the target carrier by etching, which are the first patterned groove 4, the second patterned groove 5 and the third patterned groove 6, respectively. The surfaces of the groove 4, the second patterned groove 5, and the third patterned groove 6 and the first small object 7, the second small object 8 and the third small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com