Rice crust production equipment

A kind of production equipment and rice cracker technology, applied in the field of rice cracker production equipment, can solve the problems of no longer having the crispy taste of traditional crispy rice, unable to meet people's eating needs, sticking teeth, etc., and achieve the effect of improving appearance and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be further described in detail below by describing the embodiments in conjunction with the accompanying drawings.

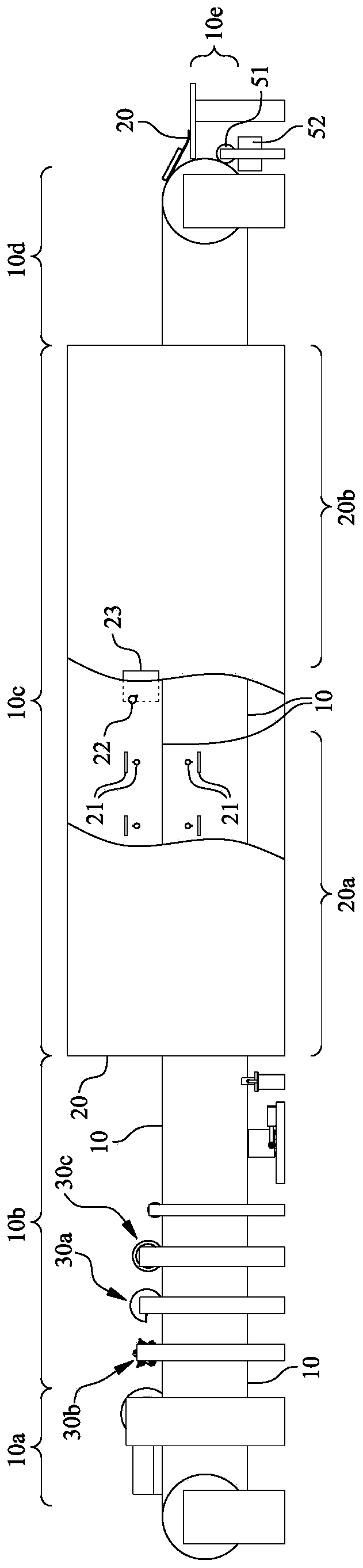

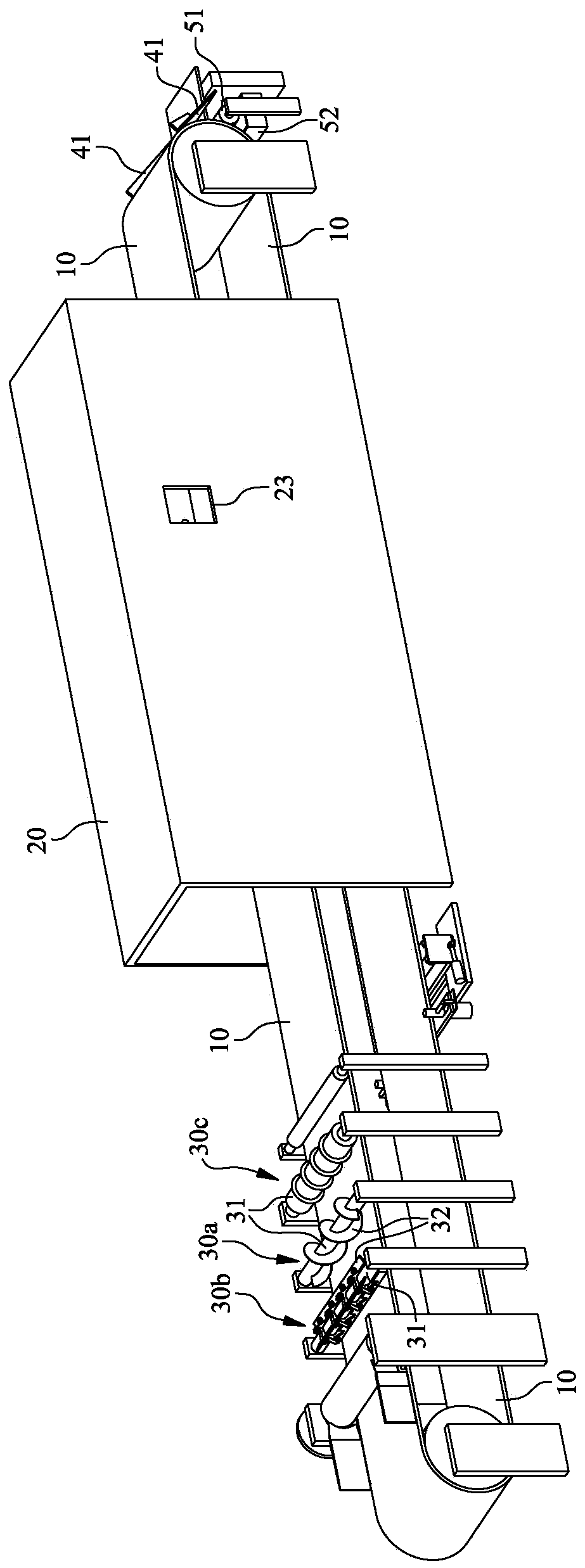

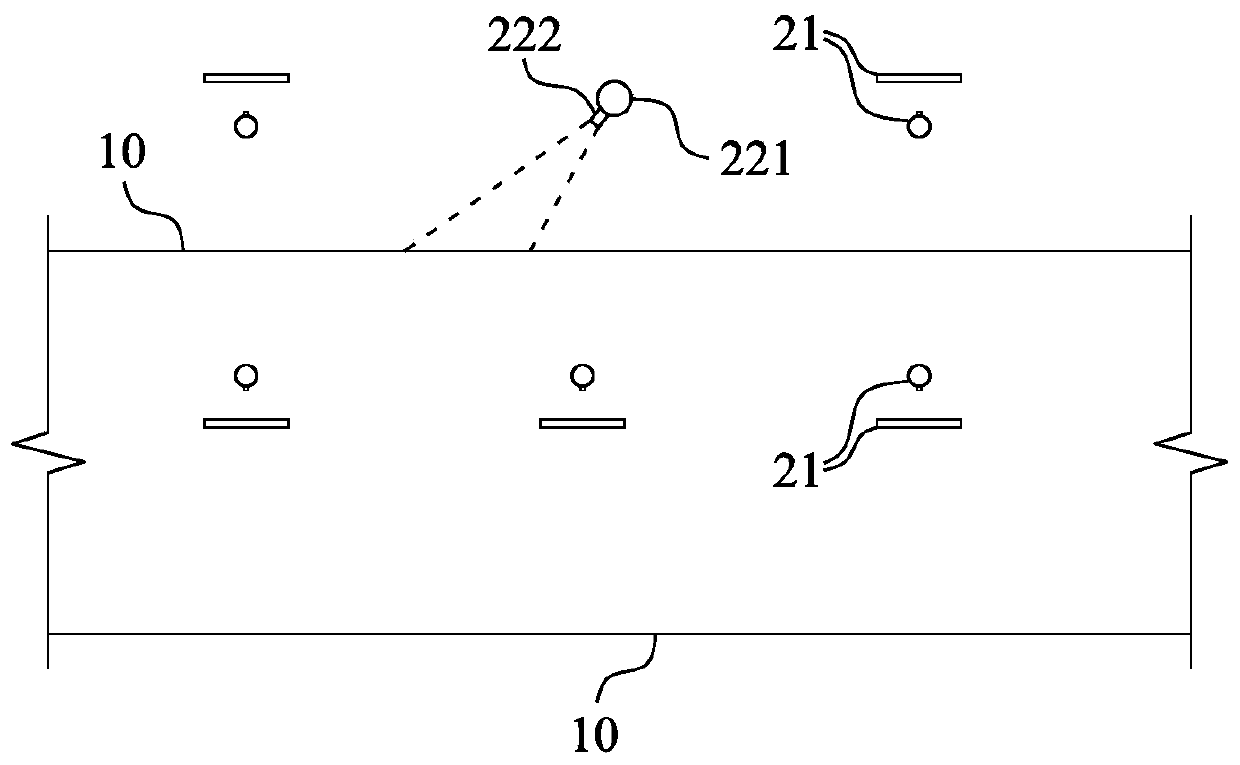

[0013] A kind of crispy rice production equipment, the displacement path of the conveyor belt 10 is sequentially arranged with a distribution section 10a, a cutting section 10b, a baking section 10c and a cleaning section 10e, and the baking section 10c is provided with a furnace body 20 extending along the conveying direction of the conveyor belt 10 A heating unit 21 is arranged inside the furnace body 20 along its extension direction, and a spray unit 22 is arranged inside the middle section of the furnace body 20 .

[0014] When producing crispy rice, the cooked material is evenly spread on the conveyor belt 10 in the cloth section 10a, then cut into pieces of appropriate size at the cutting section 10b, and sent to the baking section 10c to be baked until the first ripening is slightly yel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com