Mechanical water concentration device for agriculture seeds

A technology for agricultural seeds and mechanical water, applied in the field of machinery and equipment, can solve problems such as seed damage, and achieve the effects of ensuring sealing, strengthening dispersion effect, and improving flipping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

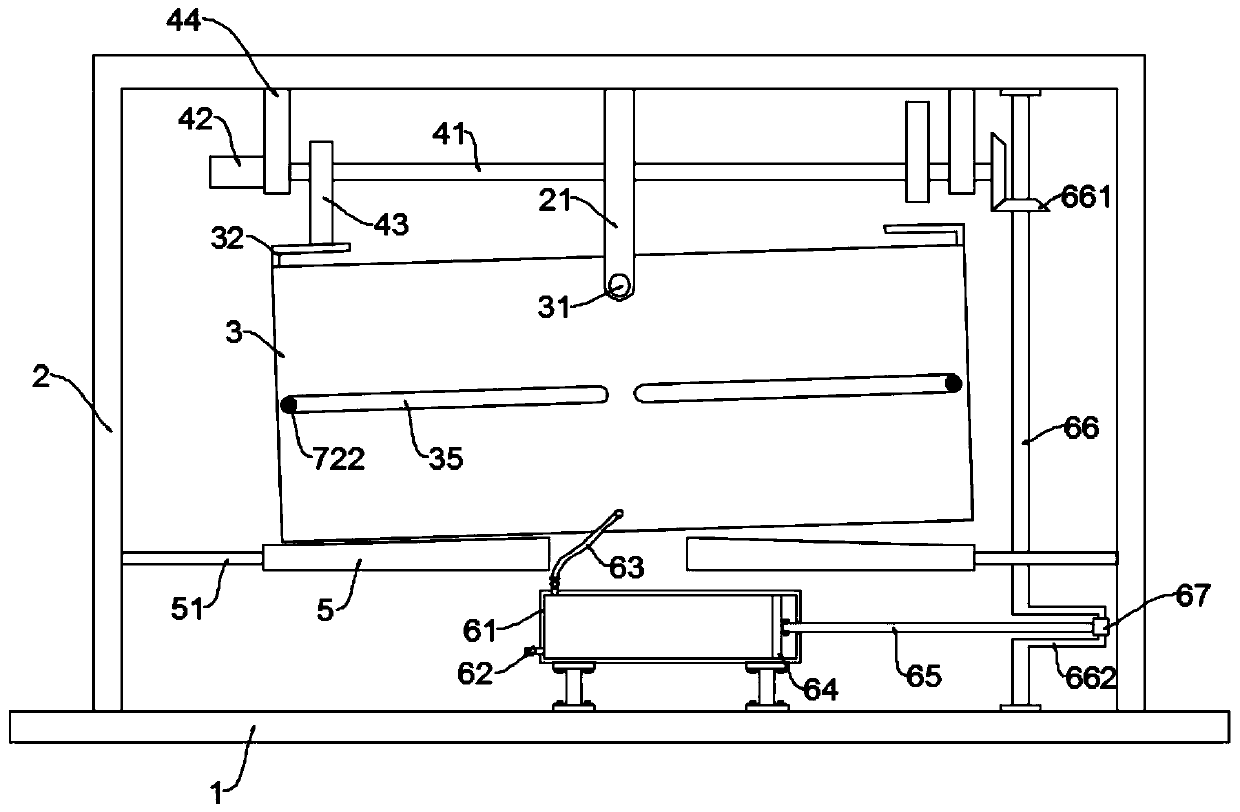

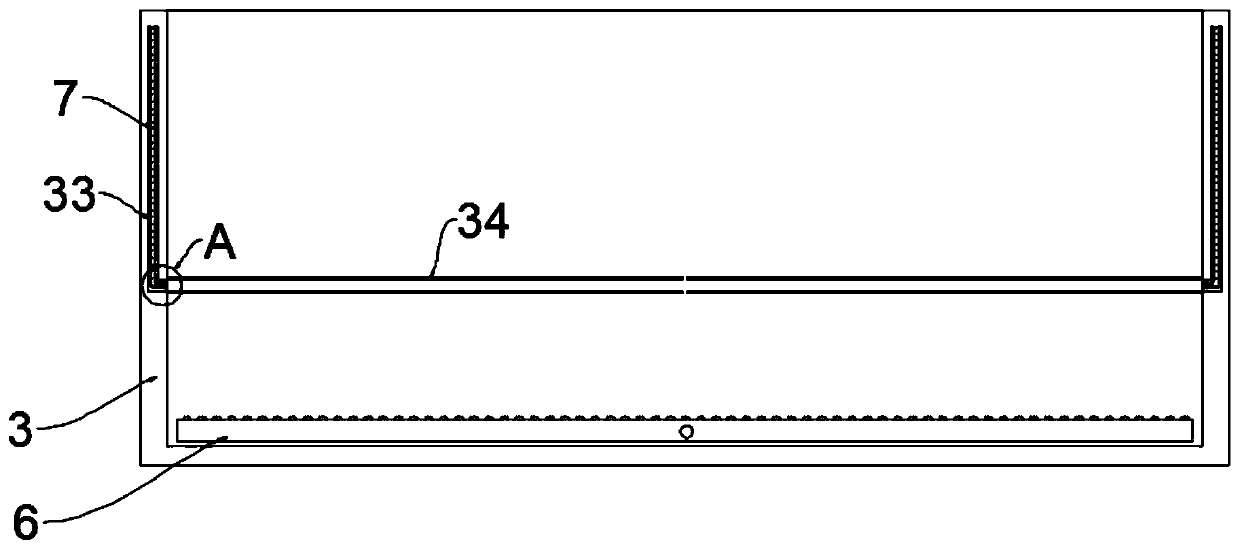

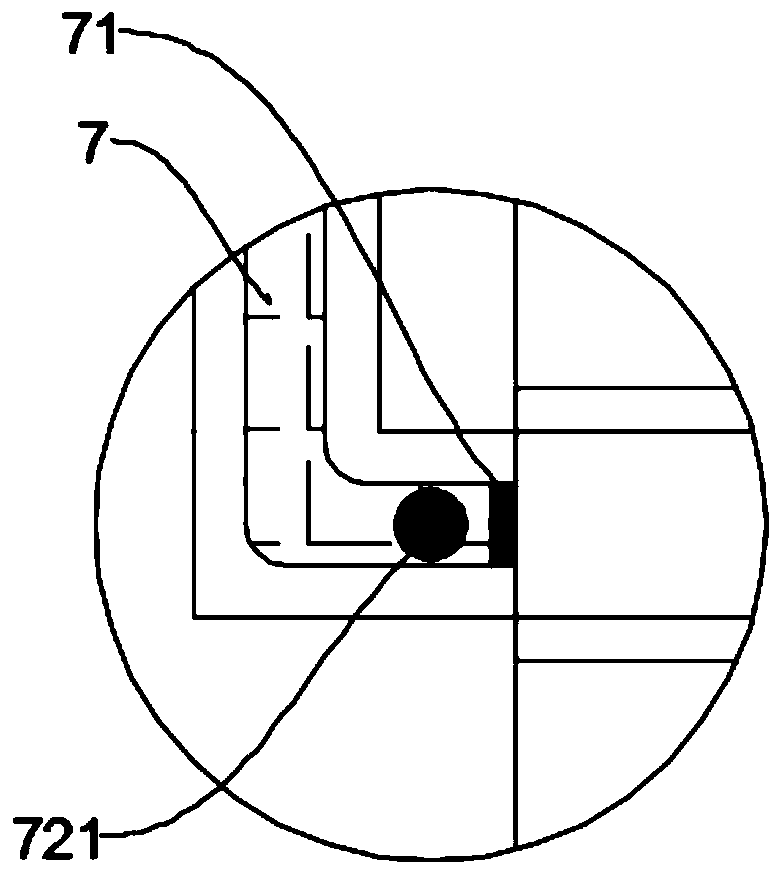

[0024] see Figure 1~5 , in an embodiment of the present invention, a mechanical water separation device for agricultural seeds includes a base 1, a support frame 2 and a water storage frame 3, and the water storage frame 3 has a drain pipe; the inner top surface of the support frame 2 is fixed with The connecting frame 21, the end of the connecting frame 21 is rotatably connected to the pin shaft 31 fixed on the outer wall of the water storage frame 3, and the support frame 2 is also provided with a drive mechanism that drives the water storage frame 3 to shake; the drive mechanism includes a rotating shaft 41 and a motor 42 , wherein the rotating shaft 41 is rotatably connected to two vertical plates 44 fixed on the support frame 2, the motor 42 is installed on one of the vertical plates 44, and the periphery of the rotating shaft 41 is sleeved and fixed with two cams 43, and the water storage frame 3 The top of the top is fixed with a contact plate 32 corresponding to the t...

Embodiment 2

[0034] Embodiments of the present invention provide a method for using the mechanical water separation device as described in Embodiment 1, specifically as follows:

[0035] Add water with a certain liquid level in the water storage frame 3, add the seeds to be selected into the water storage frame 3, start the motor 42 to make the drive mechanism run to drive the water storage frame 3 to rotate, and also the piston plate in the cylinder 61 64 starts to move back and forth, and the two cooperate to disperse the seeds, avoiding the impact of seed accumulation on the floating of dry seeds. After the water separation is completed, use the external active magnetic block 722 to make the two intercepting nets 7 stretch out and combine Together, then open the drain pipe of the water storage frame 3 to drain, the full seeds are discharged with the water flow, and the dry seeds are intercepted by the interception net 7, so far, the water selection of the seeds has been completed, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com