Vacuum extrusion molding cement fiber wallboard production line and vacuum extrusion molding cement fiber wallboard processing technology

A cement fiber and production line technology, applied in the field of vacuum extrusion cement fiber wallboard production line and its processing technology, can solve the problems of low degree of automation, low efficiency, unusable strength and frost resistance, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

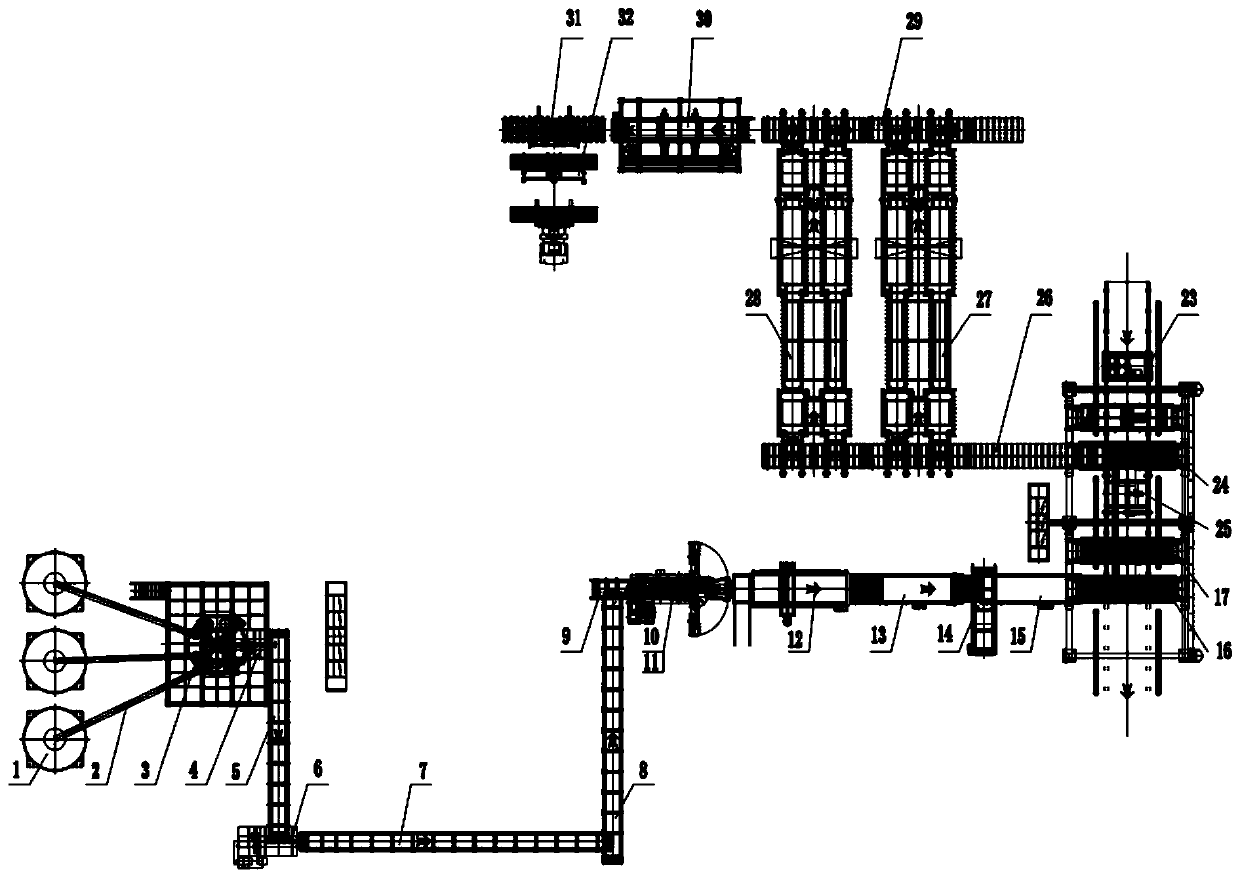

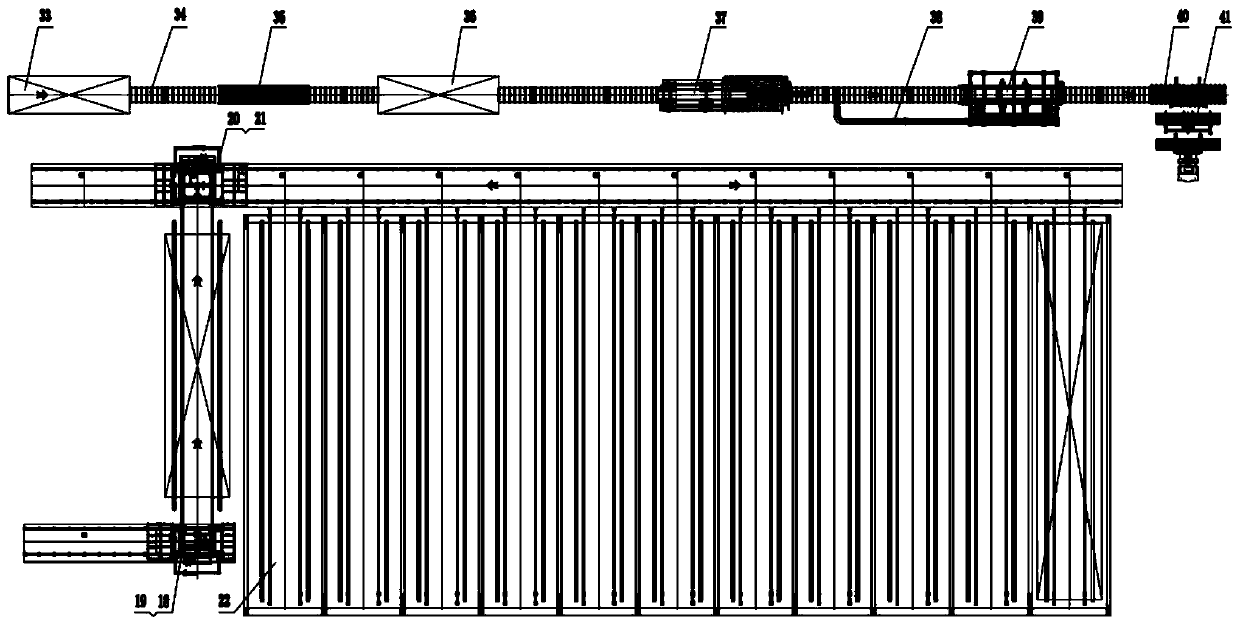

[0021] The present invention provides such Figure 1-2 A cement fiber wallboard production line, comprising a material tank 1, a vacuum extrusion machine 11, a wet billet lifting and conveying roller machine 16, a dry billet lifting and conveying roller machine 24 and a curing kiln 22, the material tank 1 is fed by a screw The material machine 2 is connected to the vertical shaft high-speed mixer 3, and the output end of the vertical shaft high-speed mixer 3 is connected to the first kneader 4 with a pipeline, and the output end of the first kneader 4 is connected to the first belt conveyor 5 Docking, the other end of the first belt conveyor 5 is connected to the second kneader 6, the output end of the vacuum extruder 11 is connected to the synchronous cutting machine 12, and the output end of the synchronous cutting machine 12 is connected to the synchronous conveyor 13 docking, the front side of the curing kiln 22 is provided with a kiln loading trolley 20 and a kiln loading...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap