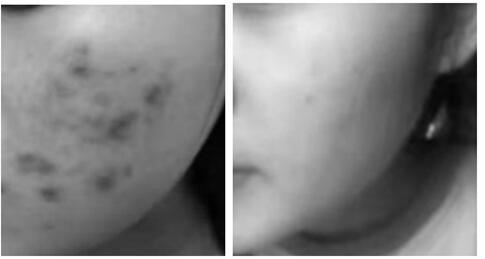

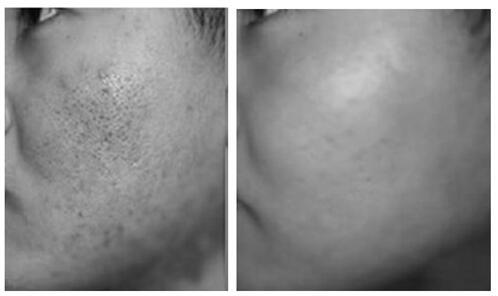

Acne-removing soap prepared by taking eucommia oil refining byproducts as raw materials and preparation method thereof

A technology of by-product and soap, applied in the field of Eucommia ulmoides processing, can solve problems such as hidden dangers of clean production, polluted soil, no document disclosure, etc., and achieve the effects of reducing irritation, realizing reuse, and easy cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Taking the laboratory test as an example, the preparation method of the acne-removing soap made from the by-products in Eucommia oil refining comprises the following steps:

[0048] (1) Put the filter paper in the Buchner funnel, then place the funnel on the suction filter bottle with the sealing ring, connect the suction filter bottle and the vacuum pump with a rubber tube; The oil content in the soapstock is about 0.1%;

[0049](2) Put 20 parts of Eucommia saponins into the Buchner funnel, open the vacuum pump, filter out the excess grease in the Eucommia saponins; set the vacuum degree of the vacuum pump to be about 0.8MPa;

[0050] (3) Put 80 parts of soap base into a beaker and heat it with a digital display constant temperature water bath to melt it; the heating time in the water bath is until the soap base melts, and the temperature is 65°C;

[0051] (4) Put the weighed and filtered eucommia saponins into the melted soap base, continue heating to make it melt an...

Embodiment 2

[0058] Taking the laboratory test as an example, the preparation method of the acne-removing soap made from the by-products in Eucommia oil refining comprises the following steps:

[0059] (1) Put the filter paper in the Buchner funnel, then place the funnel on the suction filter bottle with a sealing ring, and connect the suction filter bottle and the vacuum pump with a rubber tube;

[0060] (2) 15 parts of eucommia soapstock are put into Buchner funnel, open vacuum pump, filter out unnecessary grease in the eucommia soapstock; The vacuum degree of setting vacuum pump is 0.6MPa,

[0061] (3) Put 85 parts of soap base into a beaker and heat it to about 60°C with a digital constant temperature water bath to melt it;

[0062] (4) Put the weighed and filtered Eucommia saponins into the melted soap base, continue heating to about 60°C to make it melt and mix evenly;

[0063] (5) Pour the homogeneous soap liquid obtained in (4) into the mould, make it cool and finalize the shape; ...

Embodiment 3

[0066] Taking the laboratory test as an example, the preparation method of the acne-removing soap made from the by-products in Eucommia oil refining comprises the following steps:

[0067] (1) Put the filter paper in the Buchner funnel, then place the funnel on the suction filter bottle with a sealing ring, and connect the suction filter bottle and the vacuum pump with a rubber tube;

[0068] (2) put 15 parts of Eucommia saponins into the Buchner funnel, open the vacuum pump, filter out the unnecessary grease in the Eucommia saponins; the vacuum degree of setting vacuum pump is 0.9MPa,

[0069] (3) 85 parts of soap base, put it into a beaker and heat it to about 70°C with a digital constant temperature water bath to make it melt;

[0070] (4) Put the weighed and filtered eucommia saponins into the melted soap base, continue heating to about 70°C to make it melt and mix evenly;

[0071] (5) Pour the homogeneous soap liquid obtained in (4) into the mould, make it cool and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com