Tunnel boring machine propulsion valve group adopting full cartridge valve control

A technology for controlling tunnels and cartridge valves, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve the problems that product solutions cannot meet the application requirements, and achieve the effects of reduced weight and volume, high strength, and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

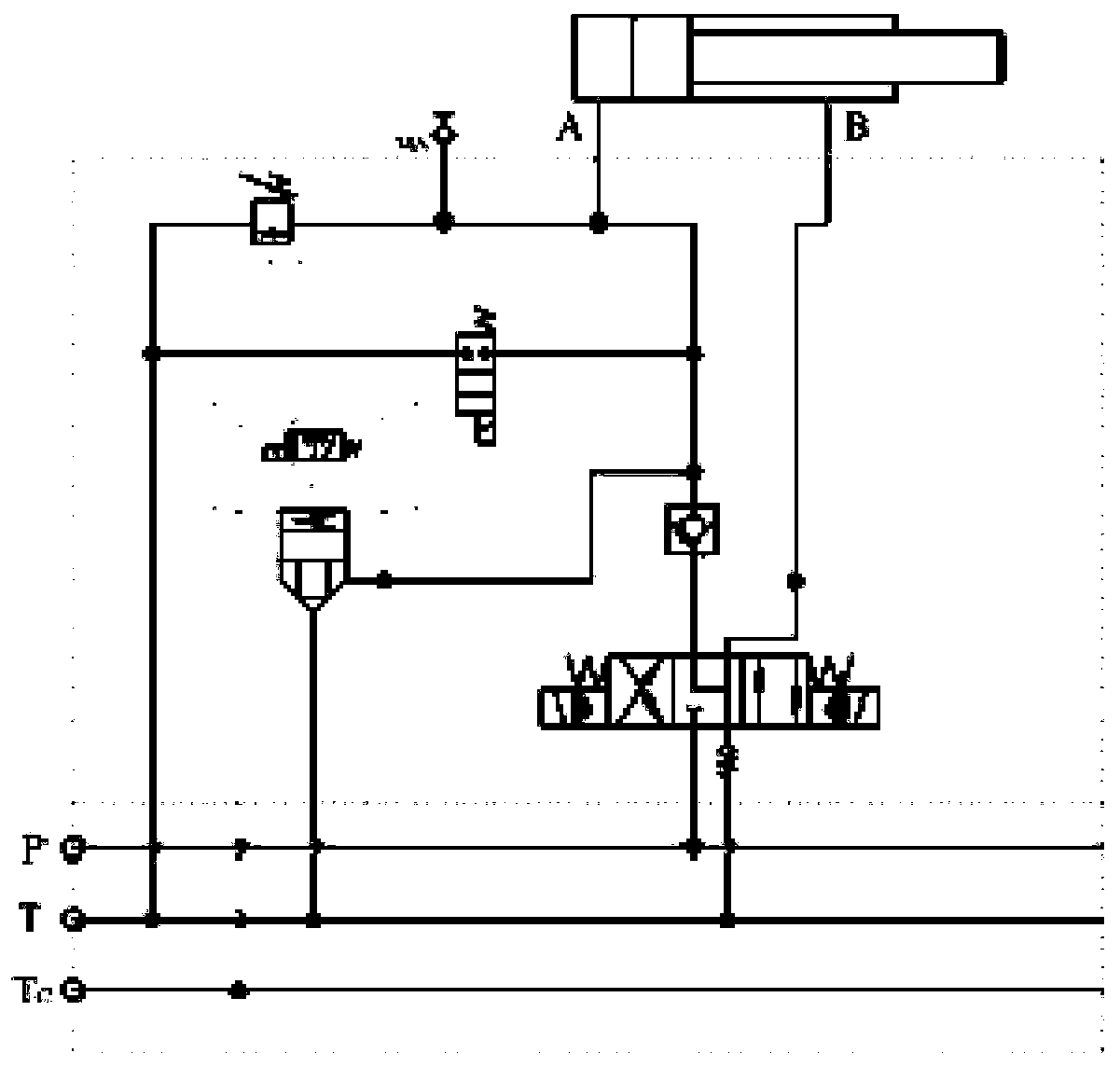

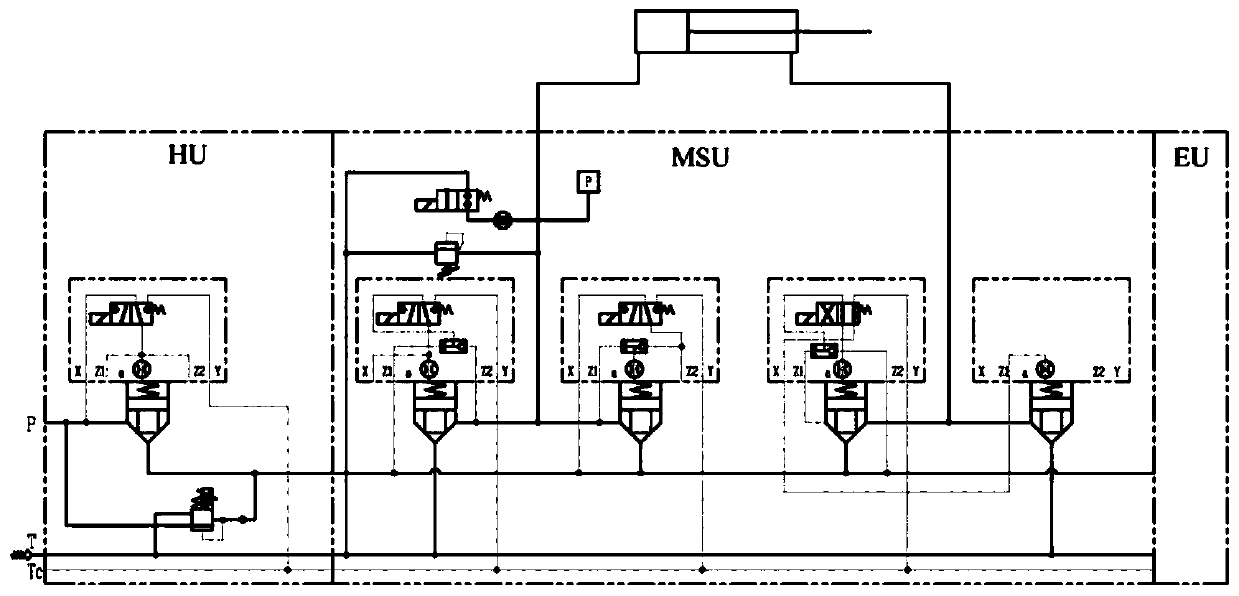

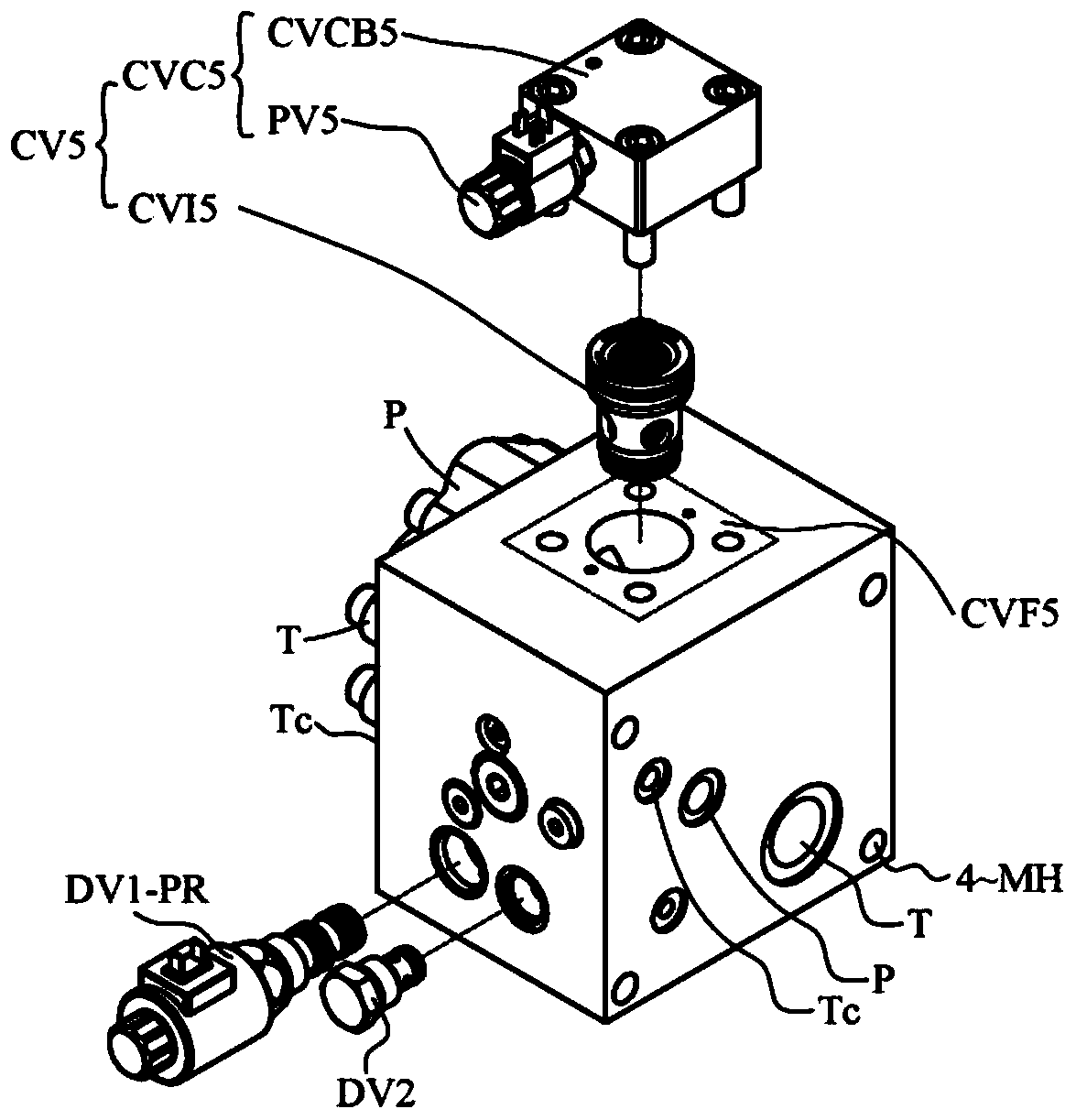

[0031] In this embodiment, the propulsion cylinder of a 6m tunnel boring machine is taken as the control object as an example. The main control requirements of the tunnel boring machine cylinder (including cylinder diameter, rod diameter, stroke, working pressure, and speed requirements during extension and retraction) are measured and calculated. Output: When the oil cylinder is extending, the flow rates of the rodless cavity and the rod cavity are 67L / min and 19L / min respectively; 35L / min. Then carry out specification matching according to the calculated flow rate. The compact two-way cartridge valve for controlling the rodless chamber of the tunnel boring machine cylinder is selected with a diameter of DN16, and the compact two-way cartridge valve for controlling the rod chamber of the tunnel boring machine cylinder is selected for DN10. Diameter sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com