Gas water heater

A gas water heater, gas technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as easy corrosion of walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

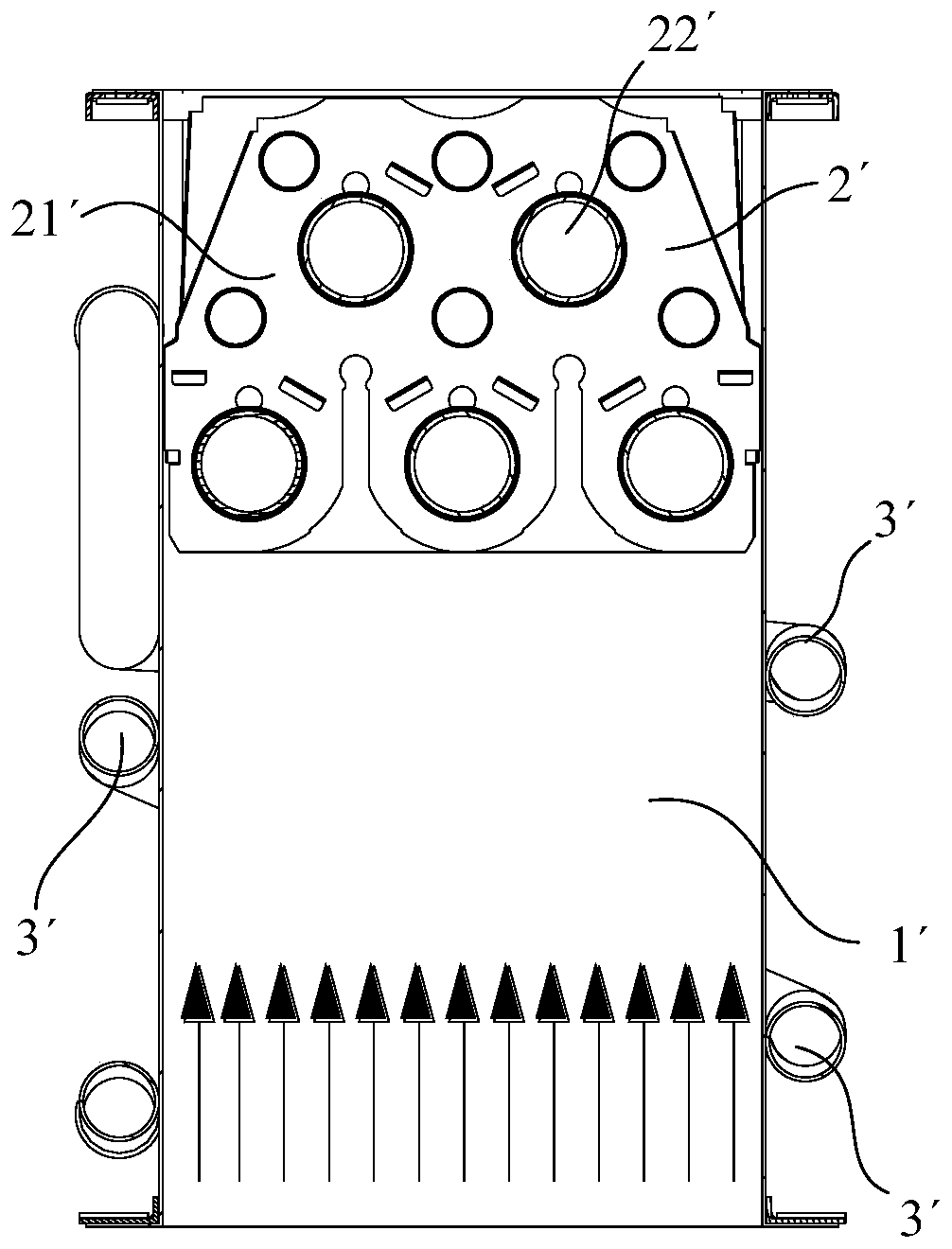

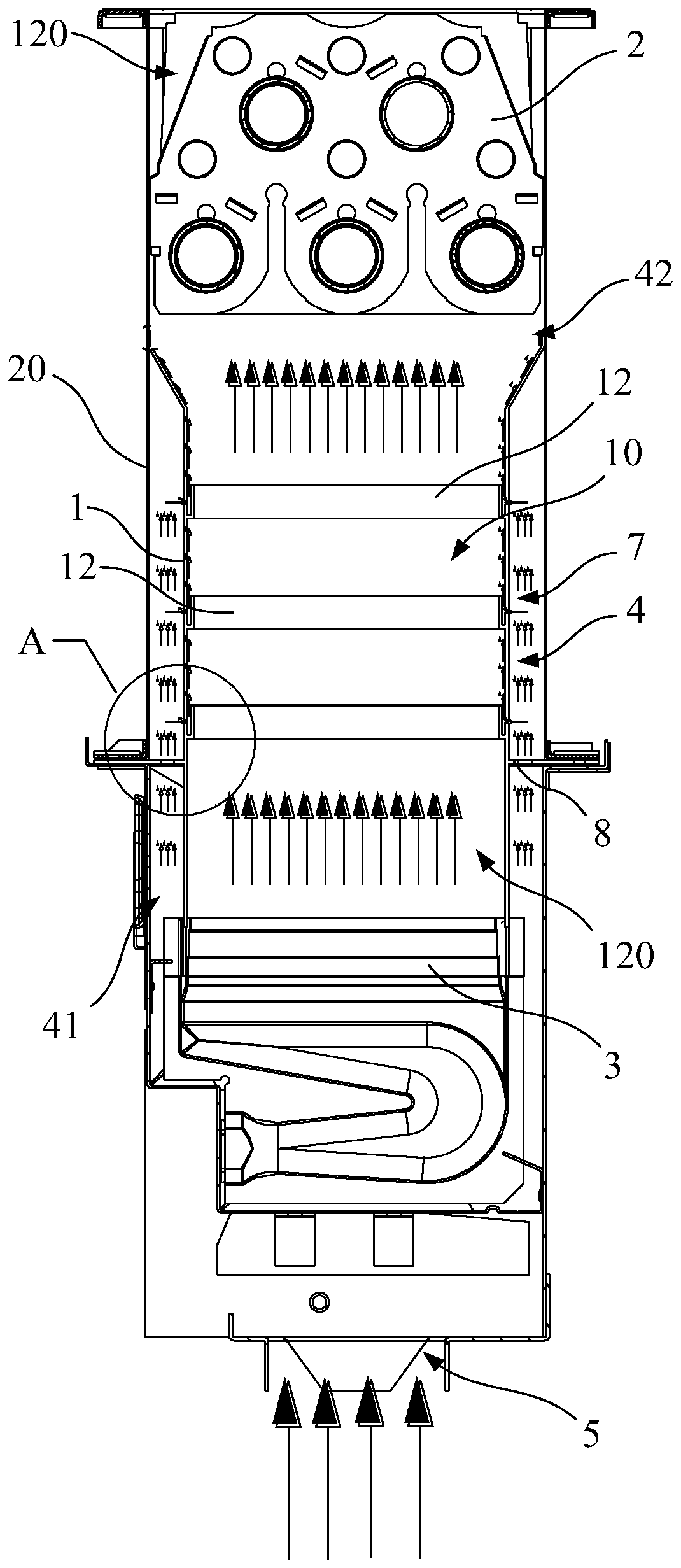

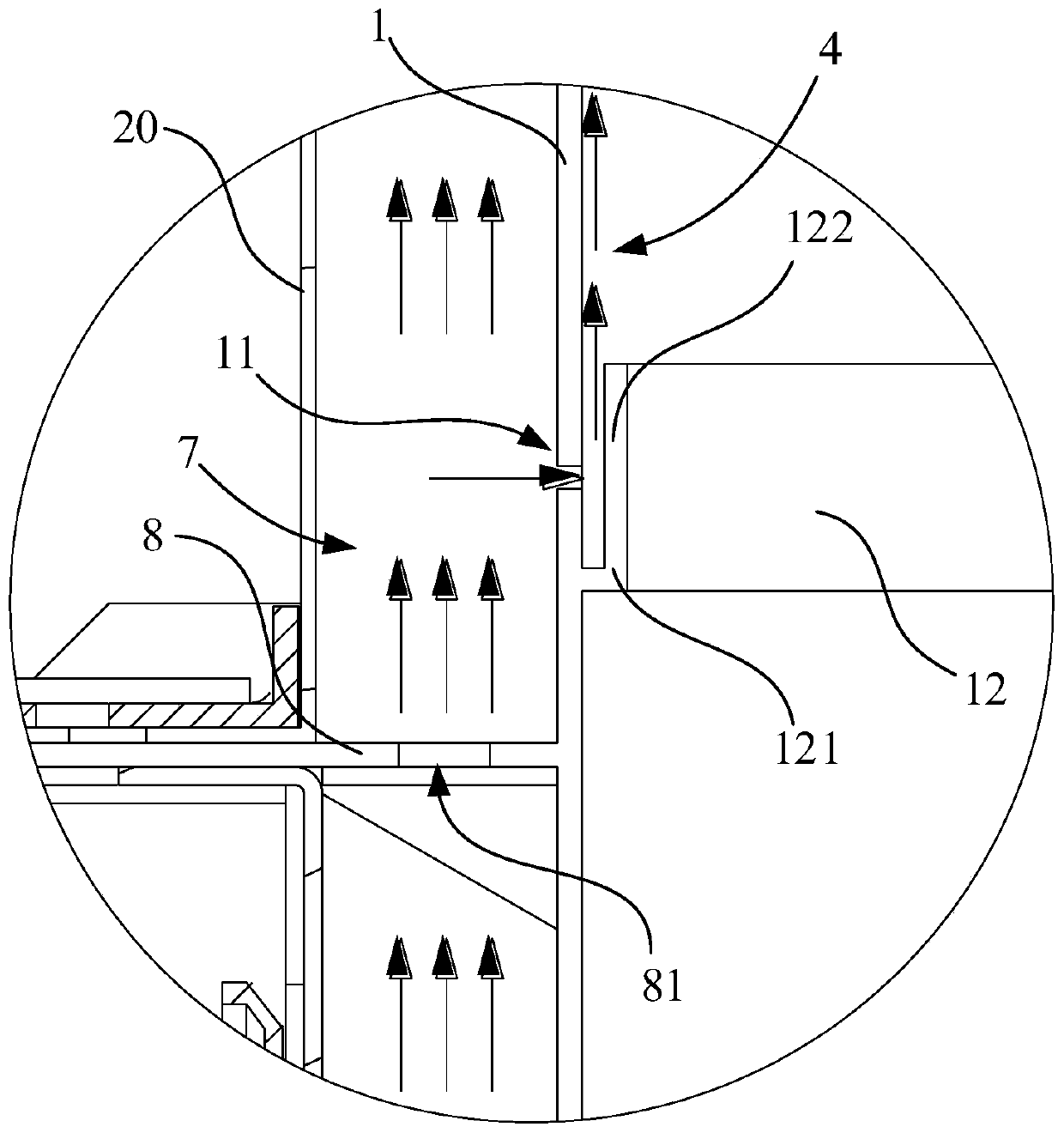

[0072] Figure 2 to Figure 5 Shown is the gas water heater of Embodiment 1 of the present invention. In this embodiment, the gas water heater includes a casing 1, a heat exchanger 2 and a burner 3, a combustion chamber 10 is formed in the casing 1, and the heat exchanger 2 is arranged in a heat exchange area 120 of the combustion chamber 10, The burner 3 is disposed in the combustion area 110 of the combustion chamber 10 . The mixture of gas and air is burned at the burner 3 , and the high-temperature flue gas generated flows to the heat exchange area 120 and exchanges heat with the heat exchanger 2 .

[0073] The gas water heater also includes an air film generating mechanism. The air film generating mechanism has an air flow path 4 flowing through the combustion chamber 10. The air flow path 4 is formed on the inner wall surface of the housing 1. The air film generating mechanism drives air to flow through the air flow path 4. The inside flows to the heat exchange area 120...

Embodiment 2

[0088] Such as Figure 6 and Figure 7 As shown, it is the gas water heater of embodiment 2 of the present invention, the gas water heater of embodiment 2 is basically the same as embodiment 1, the difference is: the fan 6 is arranged at the end 42 of the air flow path 4, and the fan 6 is an exhaust fan 6.

[0089] The exhaust fan 6 can extract air from the end 42 of the air flow passage 4 , so as to realize the function of driving air to flow in the air flow passage 4 . The end 42 of the air flow passage 4 coincides with the smoke exhaust passage of the heat exchange area 120, and the fan 6 is also used to drive the smoke to be discharged from the combustion chamber 10. While the fan 6 drives the air flow in the air flow passage 4, it also The driving flue gas is discharged from the combustion chamber 10, which can effectively reduce the number of components in the gas water heater.

[0090] In addition, in this embodiment, the gas water heater also includes a cooling wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com