Lubricating oil pump test bed

A technology of lubricating oil pump and test bench, which is applied in the direction of engine testing, mechanical component testing, machine/structural component testing, etc. It can solve the problems of shortened service life of equipment, facilitate disassembly and maintenance, and avoid and endanger personal Healthy, avoiding the effects of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

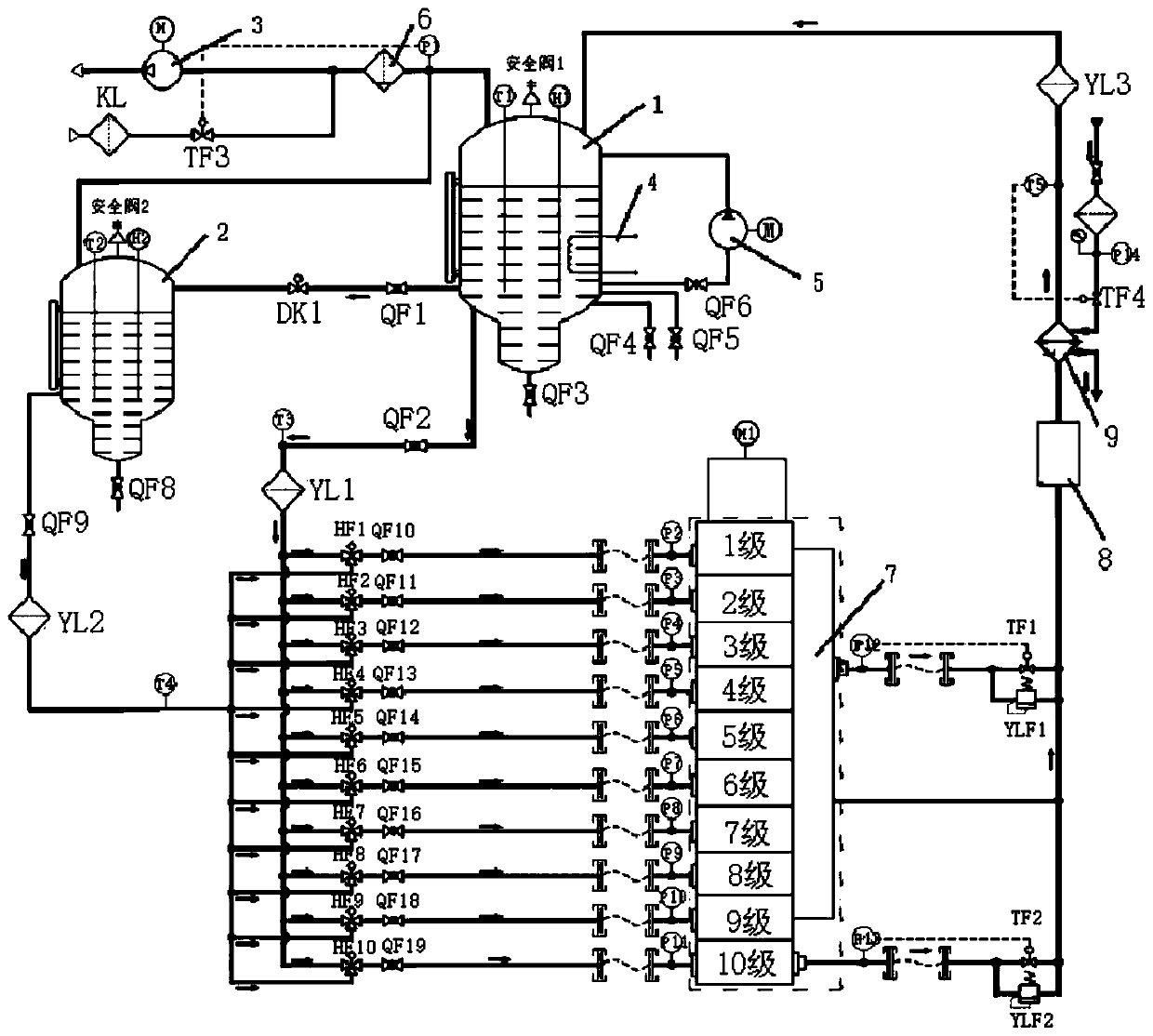

[0023] A lubricating oil pump test bench comprises a test bench on which a power transmission system, a lubricating oil system, a vacuum system, a cooling system, and an electrical control system are installed; the lubricating oil system is connected to the power transmission system, the vacuum system, and the cooling system respectively , electrical control system, and lubricating oil pump; the lubricating oil pump is installed on the test bench and connected to the lubricating oil system through pipelines.

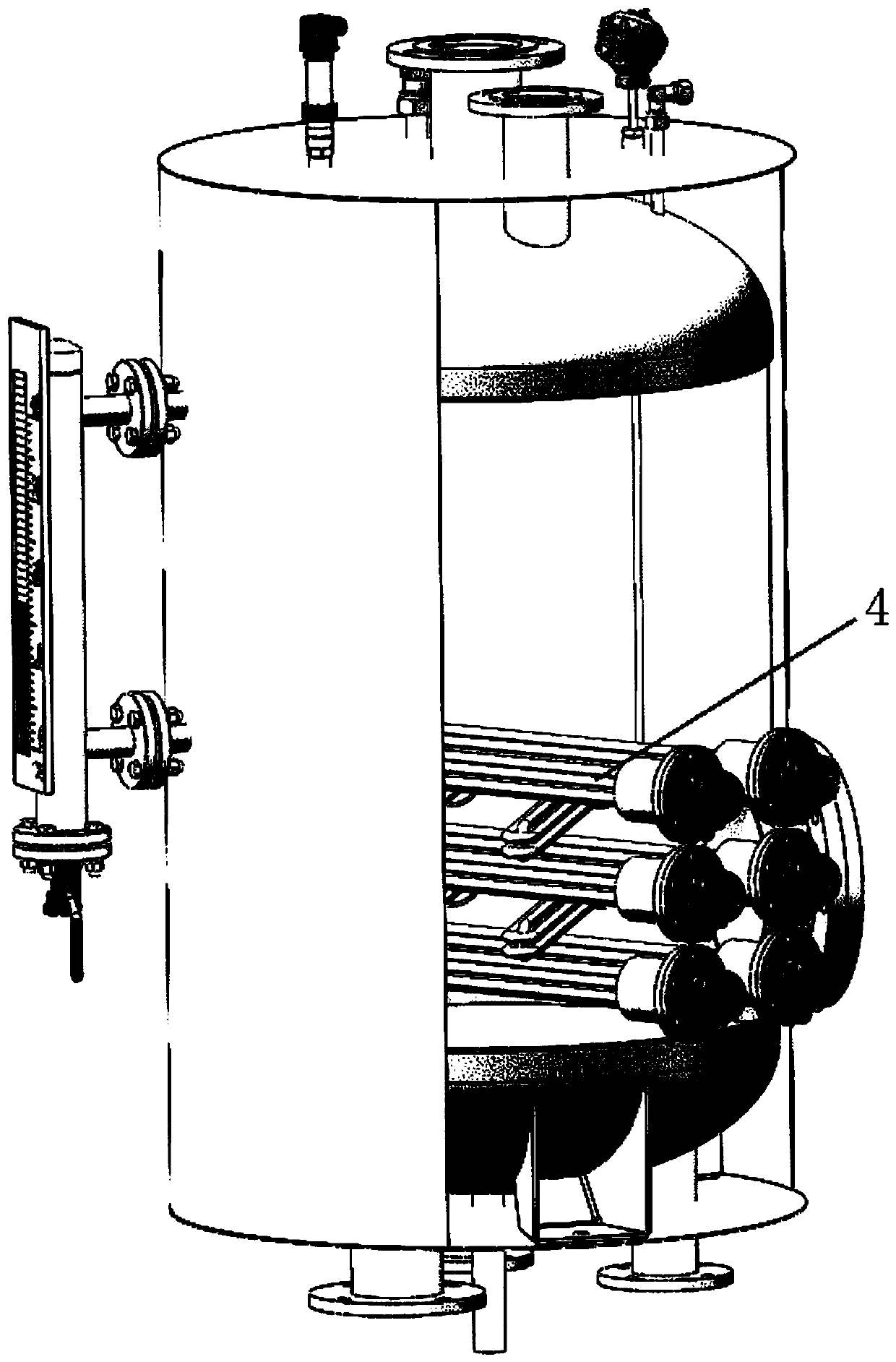

[0024] The lubricating oil system includes a main oil tank 1, a metering oil tank 2, and a pipeline system; the main oil tank 1 and the metering oil tank 2 are installed on a liftable base. The pipeline system includes a metered oil tank replenishment pipeline; the metered oil tank replenishment pipeline is arranged between the main oil tank and the metered oil tank. There are 5 outlets in the main fuel tank, 3 outlets for fuel supply and 2 outlets as spare outlets. The...

Embodiment 2

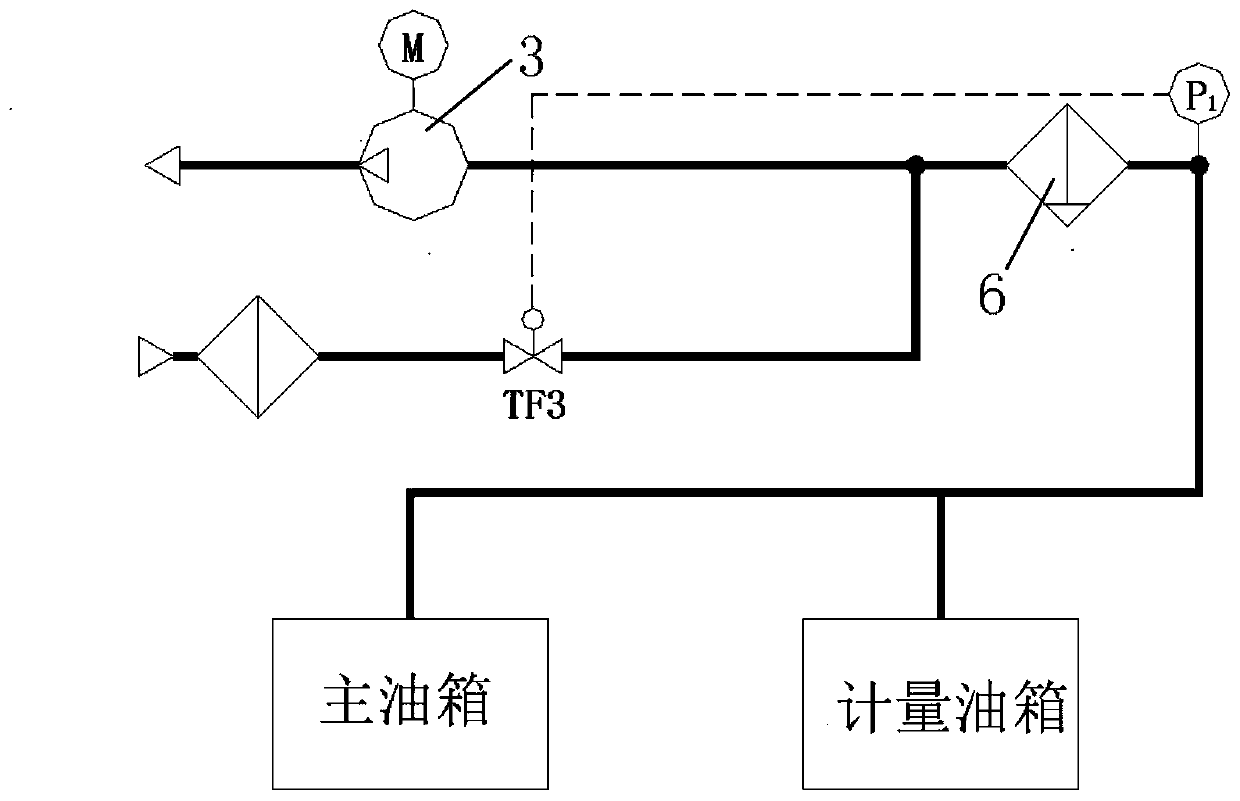

[0035] Such as figure 1 — Figure 4 As shown, the pressure on the upper part of the main oil tank is closed-loop controlled by the electric regulating valve TF3 and the pressure transmitter P1 to keep the vacuum pump working continuously and the pressure in the main oil tank stable. Oil pump single stage flow test test.

[0036] When carrying out the flow measurement test of a certain stage of the test lubricating oil pump, it is necessary to open the electric switch valve DK1 on the connecting pipeline between the main oil tank 1 and the metering oil tank 2, so that the liquid level in the metering oil tank reaches the upper limit, and then the flow measurement can be performed test. The on-off valve DK1 is automatically controlled by the electrical control system, and the test personnel only need to press the oil filling button of the metering oil tank on the operating table to complete the oil replenishment of the metering oil tank. Then select the metering oil circuit (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com