Gas shielded arc welding wire and gas shielded arc welding method

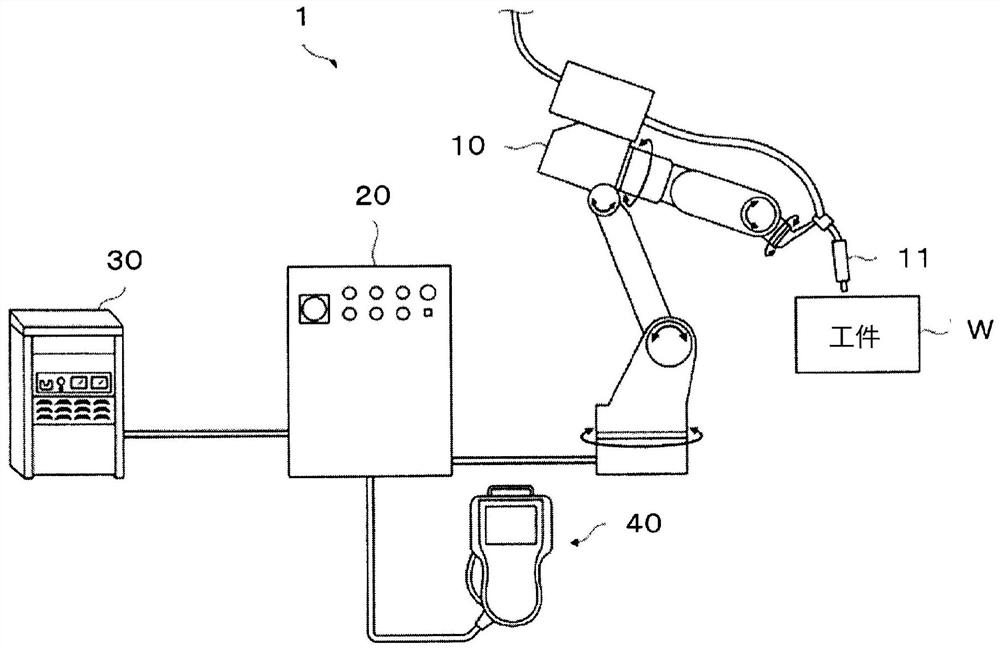

A gas shielded and arc welding technology, applied in arc welding equipment, welding equipment, welding medium, etc., can solve the problems of unconsidered welding defects, poor shape, difficult to apply automation, etc., to suppress incomplete fusion and poor weld bead shape , to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

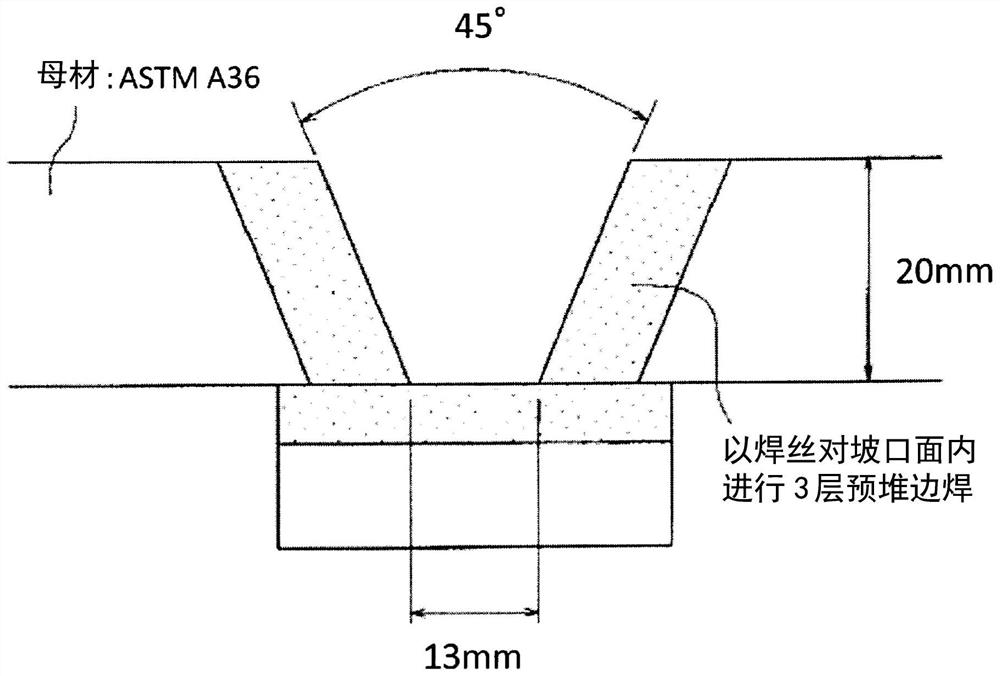

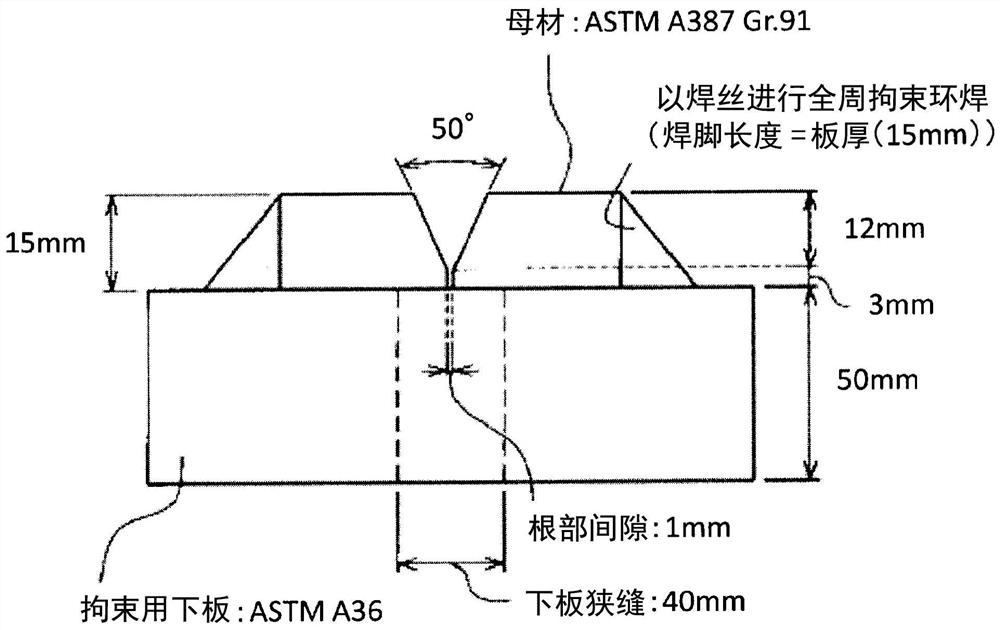

[0121] Hereinafter, the present invention will be described more specifically with reference to examples. The present invention is not limited by these examples, and can be modified and implemented within the range that can meet the gist of the present invention, and these are included in the technical scope of the present invention.

[0122] The welding wires used in this example are shown in Tables 1-4. Using this welding wire, welding was performed under the welding conditions shown below (wire diameter, welding current, arc voltage, and welding speed were constant in all Examples and Comparative Examples). In addition, the welding conditions demonstrated here are an example, and this embodiment is not limited to the following welding conditions. In addition, in Tables 5 to 9, evaluation results regarding arc stability, bead appearance, welding defects (incomplete fusion, slag inclusions, pores, etc.), hot crack resistance, toughness, and creep strength are shown.

[0123...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com