A point ring laser and arc hybrid welding method

A hybrid welding and laser arc technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unfused sides, welding bumps, undercuts, etc., to improve the forming quality, broaden the application field, reduce the The effect of additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

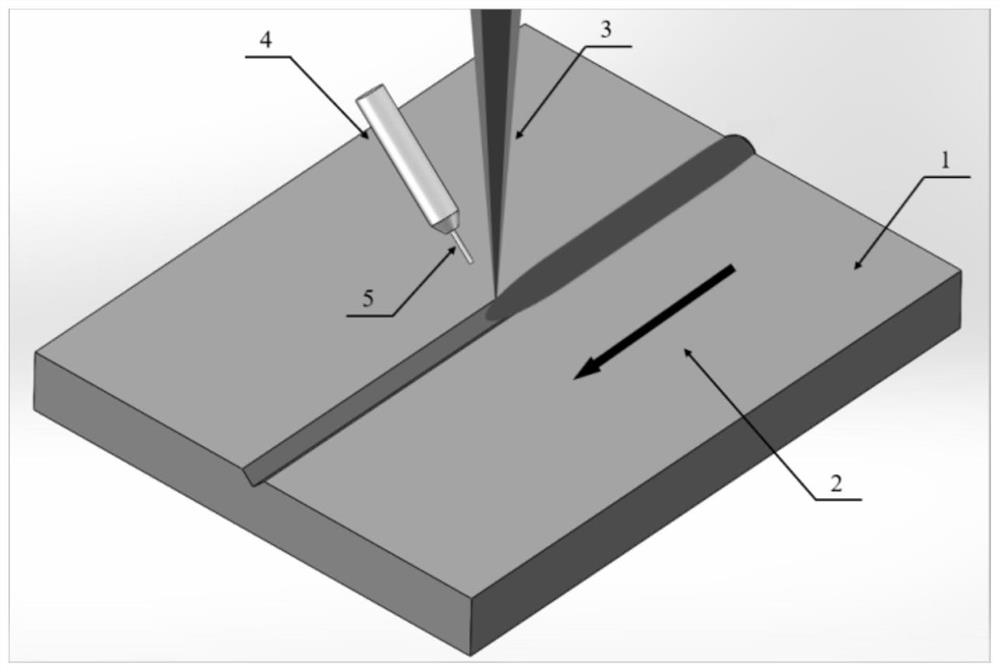

[0025] Specific embodiment one: the present embodiment is a point ring laser and arc composite welding method, which is carried out in accordance with the following steps:

[0026] First, welding before welding bevel processing and tooling fixing:

[0027] The groove is processed at the surface to be welded at the surface to be welded, and the welded surface and groove are sanded and cleaned after processing, and finally the welded surfaces of the two workpieces to be welded are closely matched and fixed;

[0028] Second, point ring laser and arc composite welding:

[0029] The laser processing head is fixed with the welding torch, and the laser is controlled to emit a point ring composite beam transmitted to the laser processing head, and the arc is arced, and the point ring laser arc composite welding is carried out under the condition of welding speed of 0.5m / min ~ 2m / min, that is, the point ring laser and arc composite welding method is completed;

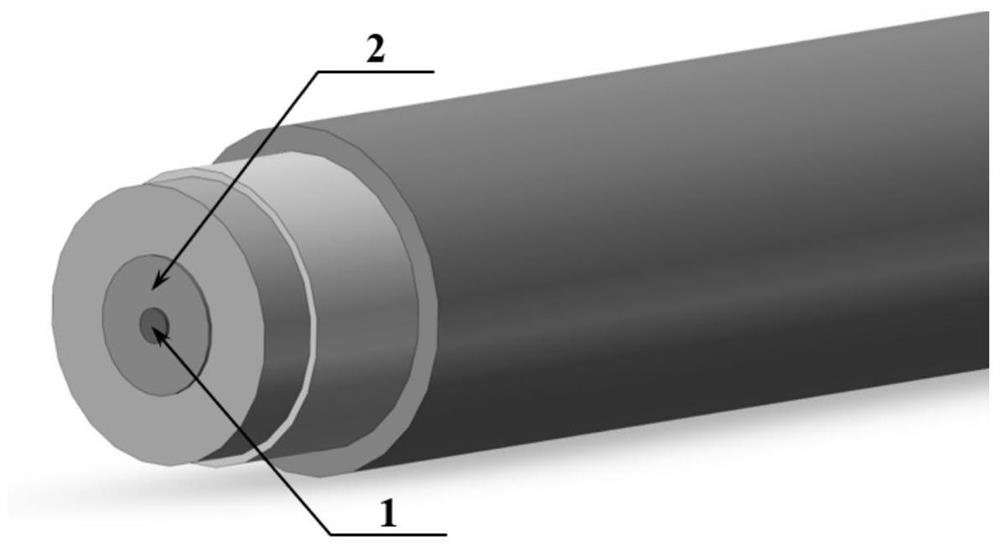

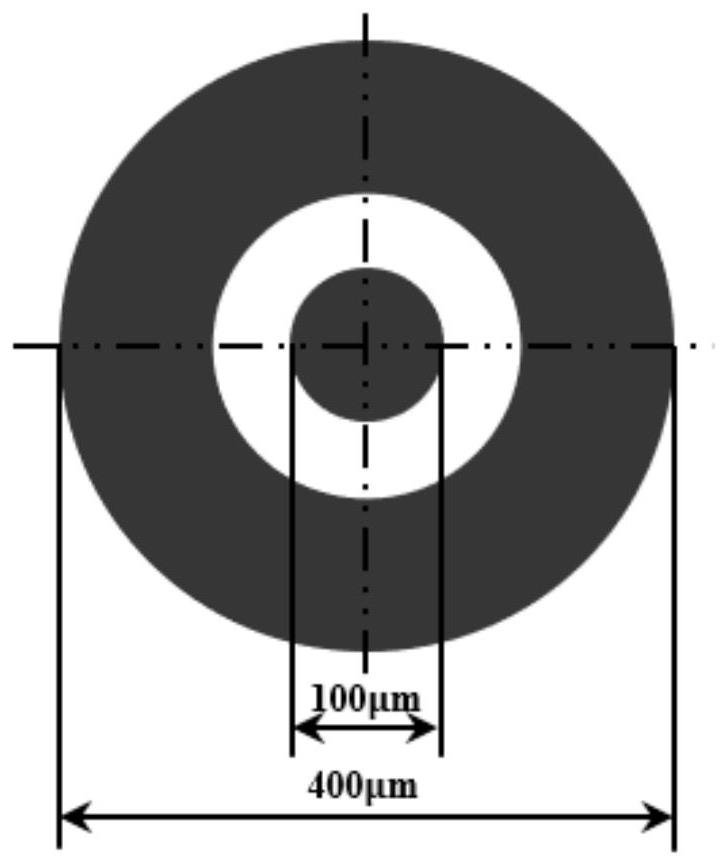

[0030]The dot ring composit...

specific Embodiment approach 2

[0039] Specific embodiment two: the present embodiment and the specific embodiment of a different is: the bevel described in step one is an I-type bevel, V-shaped bevel or Y-shaped groove. Others are the same as a specific embodiment.

specific Embodiment approach 3

[0040] Specific embodiment three: The present embodiment and one or two of the specific embodiments are different from: the material of the workpiece to be welded in step one is carbon steel, stainless steel or high strength steel. Others are identical with specific embodiments one or two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com