A systematic control method for suppressing welding defects

A welding defect and system technology, applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of affecting the mechanical properties of weldments, reducing the service life of weldments, weakening the fatigue limit of weldments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

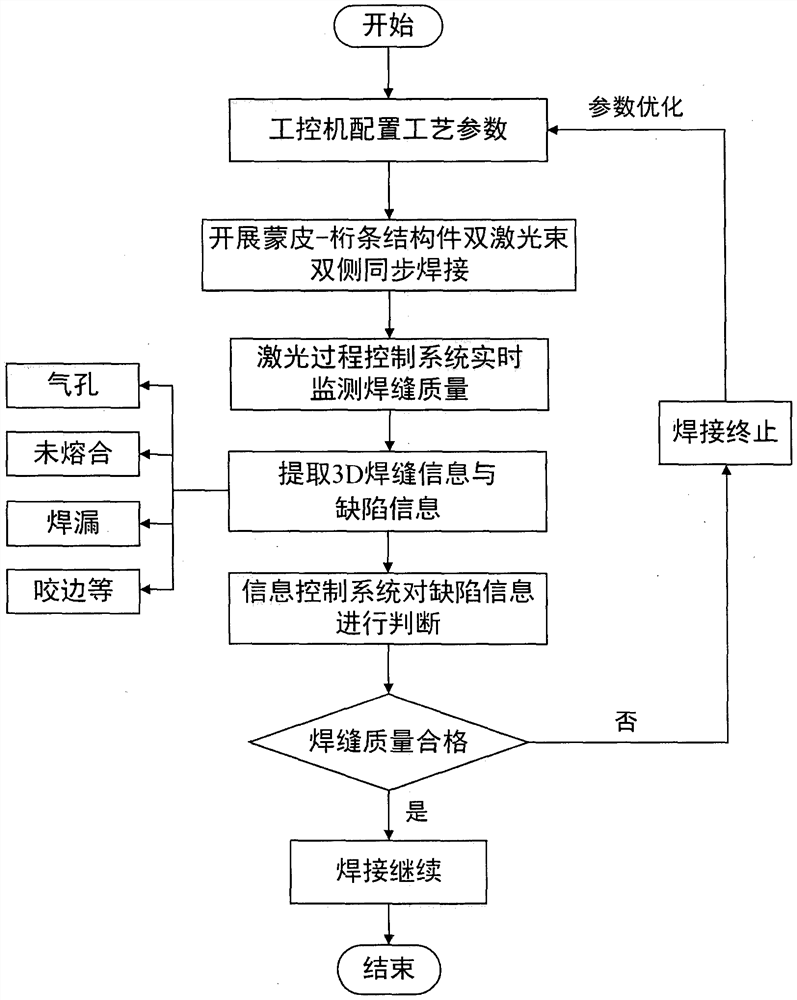

[0019] The following is a specific description of a systematic control method for suppressing welding defects of the present invention.

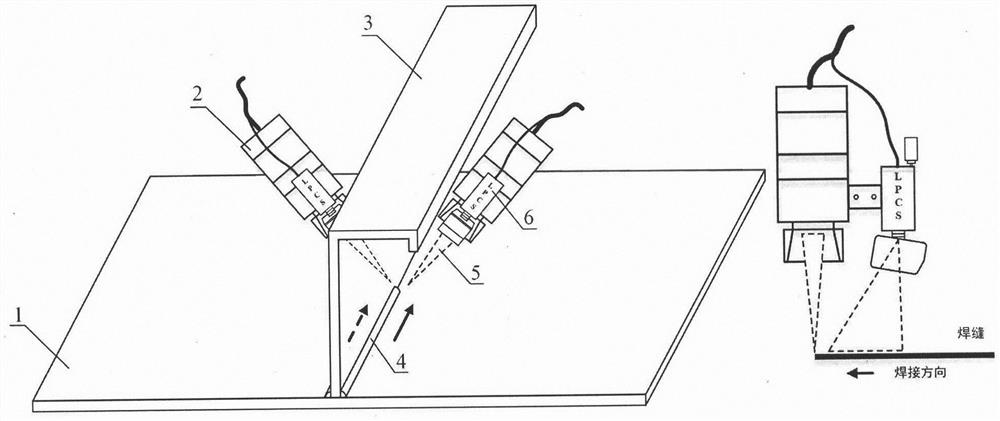

[0020] The double-laser beam double-sided synchronous welding experiment was carried out for the TC4 titanium alloy skin-stringer wall plate. The thickness of the skin was 1.2mm, and the stringer was simplified as a flat plate with a size of 500mm×100mm×2mm. The experiment uses a TruDisk 12003 disk laser with a maximum power of 12000W. The laser is equipped with one split and two optical gates. It is equipped with 2 optical fibers with a length of 30m and a core diameter of 1000μm. They are respectively connected to two laser welding heads to achieve double beams. Laser welding process.

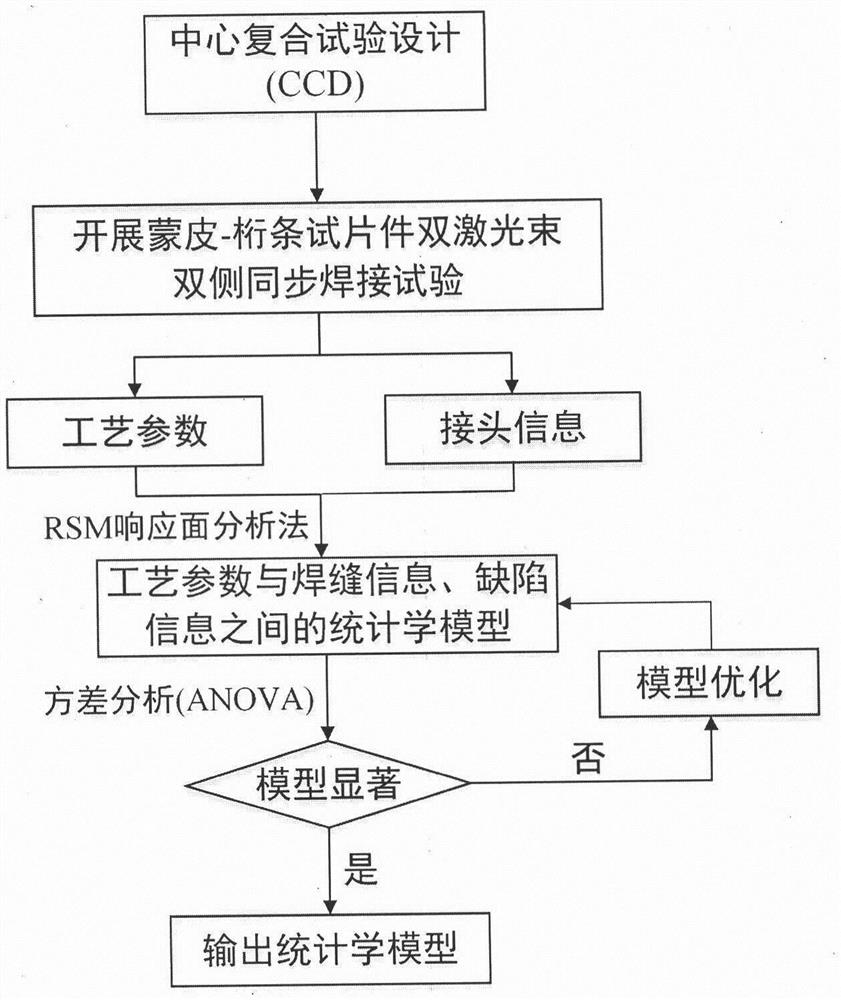

[0021] Central composite design (Central Composite Design, CCD) was used to design the experimental scheme, and a double-laser simultaneous welding experiment was carried out on the titanium alloy skin-stringer panel specimen. After the welding experiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com