Method for preparing a thermoplastic polyurethane having a low glass transition temperature

A thermoplastic polyurethane, caprolactone technology, applied in the field of thermoplastic polyurethane, can solve the problems of impairing cold flexibility, unsatisfactory mechanical properties, indivisibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

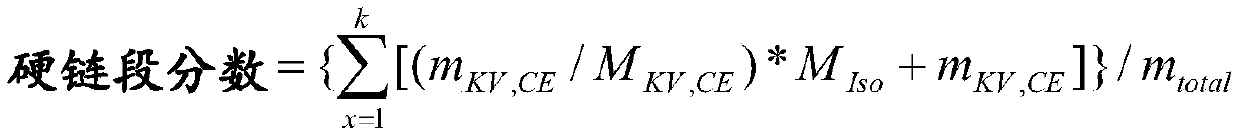

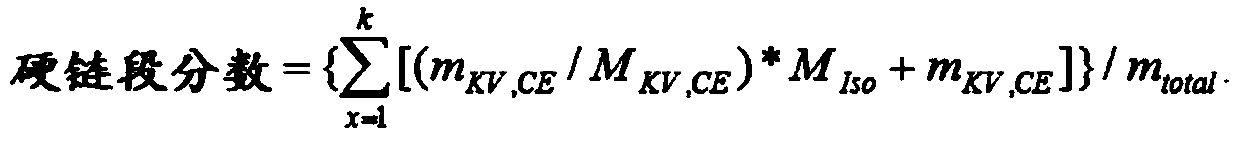

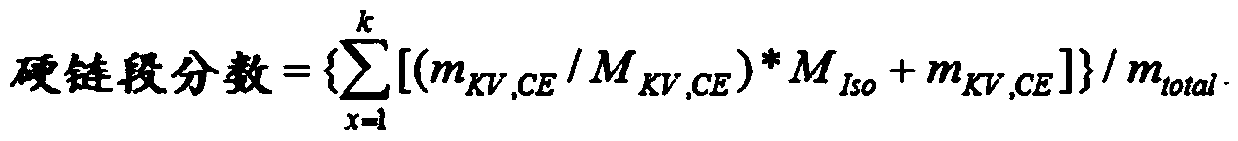

Image

Examples

Embodiment

[0315] Examples and Comparative Examples

[0316] 1. Compound

[0317] Polyester polyol

[0318]

[0319] Polyisocyanate - 4,4'-MDI from BASF with an isocyanate content of 33.5% by weight.

[0320] low molecular weight diols

[0321] CE 1 1,6-Hexanediol

[0322] CE 2 1,4-Butanediol

[0323] Obtained from Sigma Aldrich

[0324] additive

[0325] AD 1 Phenolic antioxidant stabilizer purchased from BASF

[0326] 2. Standard method

[0327]

[0328] For T determined by dynamic mechanical thermal analysis according to DIN EN ISO 6721-1:2011-08 g , all values given in this application were determined at a heating rate of 2 K / min and in 1 Hz torsional mode. Unlike the DIN specification, the temperature was adjusted in steps of 5 K with 35 s steps, which corresponds to a continuous heating rate of 2 K / min. Tests were carried out with samples having a width:thickness ratio of 1:6.

[0329] 3. Conventional TPU synthesis

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com