A rotary exhaust gas dust removal device for factories

A dust-removing device and rotary technology, applied in cleaning methods and utensils, using liquid separating agents, separating methods, etc., can solve the problems of inconvenient disassembly and replacement, waste of production time, low cleaning efficiency, etc., and achieve ingenious design of linkage structure structure. Reasonable, lower manufacturing cost, high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

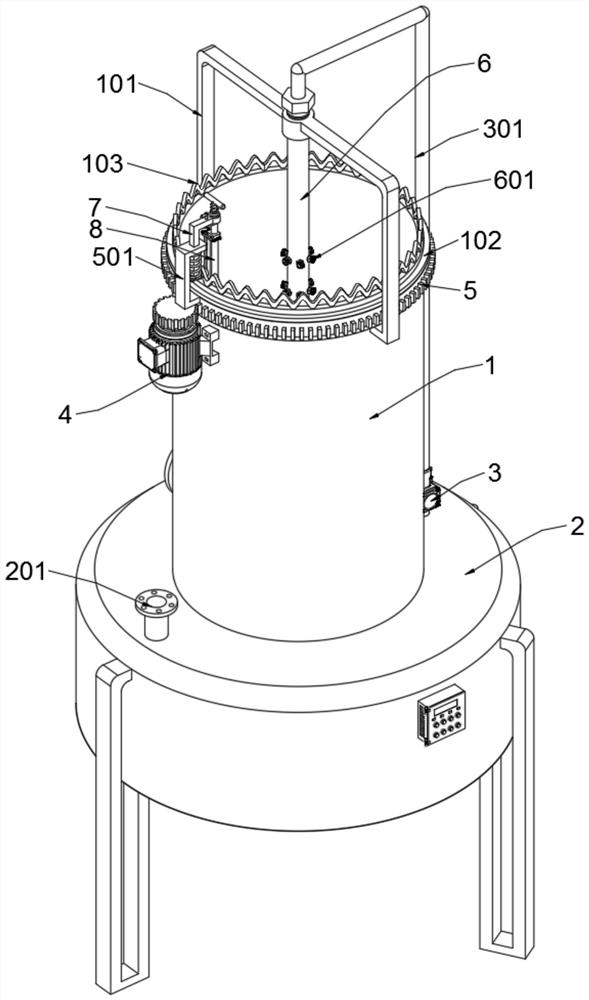

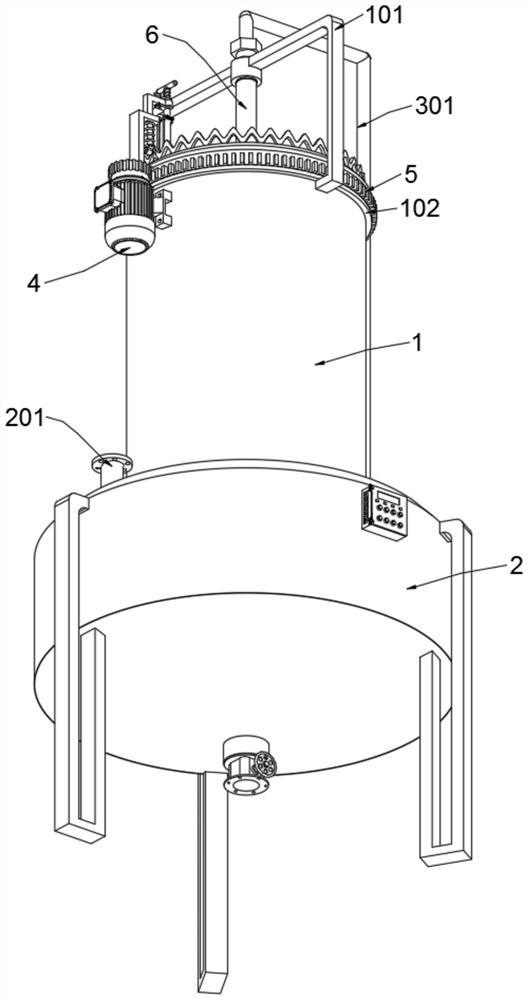

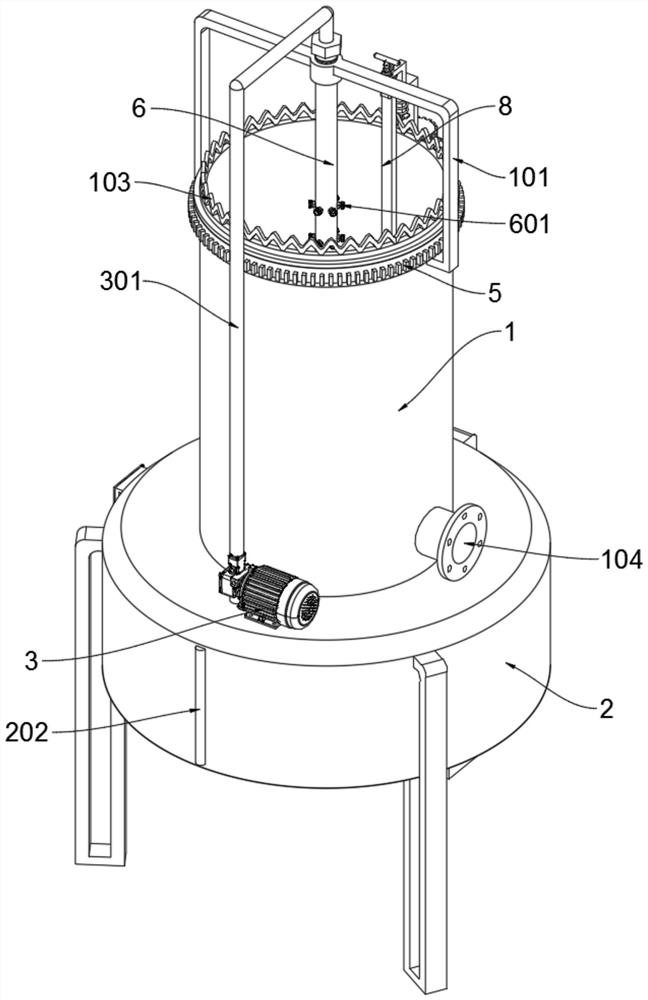

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0033] see Figure 1 to Figure 11, an embodiment provided by the present invention: a factory rotary exhaust gas dedusting device, including a settling tank 2, a circulating water pump 3, an L-shaped ejector rod 7 and a vertical support square rod 8, and the settling tank 2 includes a water supply pipe 201 And the water level glass tube 202, the bottom of the settling tank 2 is welded with a mud gathering hopper, the bottom of the gathering hopper is equipped with a discharge valve, and the annular top plate of the settling tank 2 is welded and communicated with a water supply pipe 201; The center of the top of the settling tank 2 is supported and welded with a dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com