A kind of soil remediation management system and method

A soil remediation and soil technology, applied in the field of soil remediation, can solve the problems of huge soil pollution and severe soil pollution, and achieve the effect of improving the efficiency of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

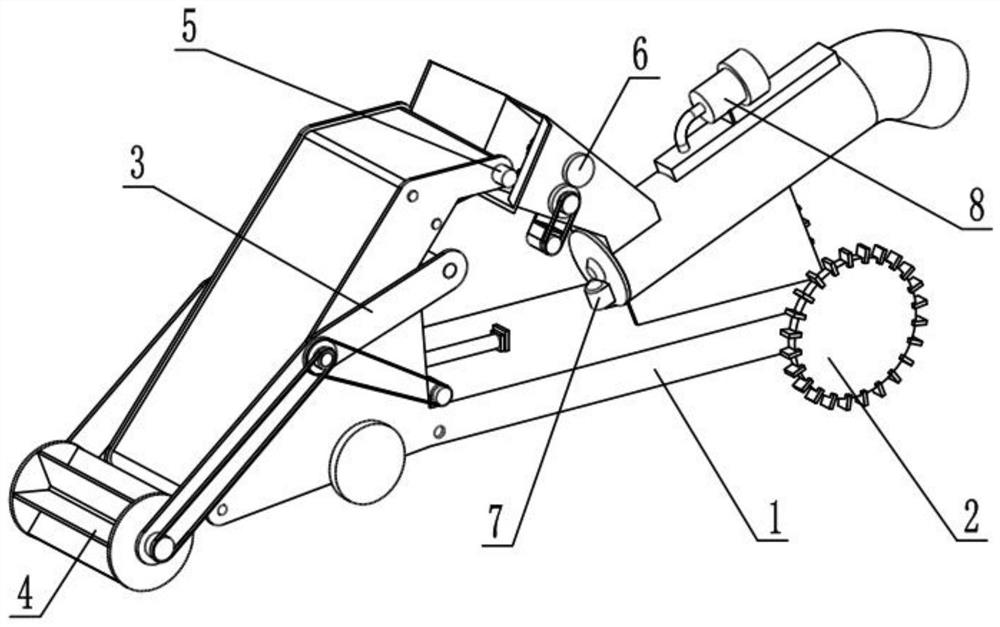

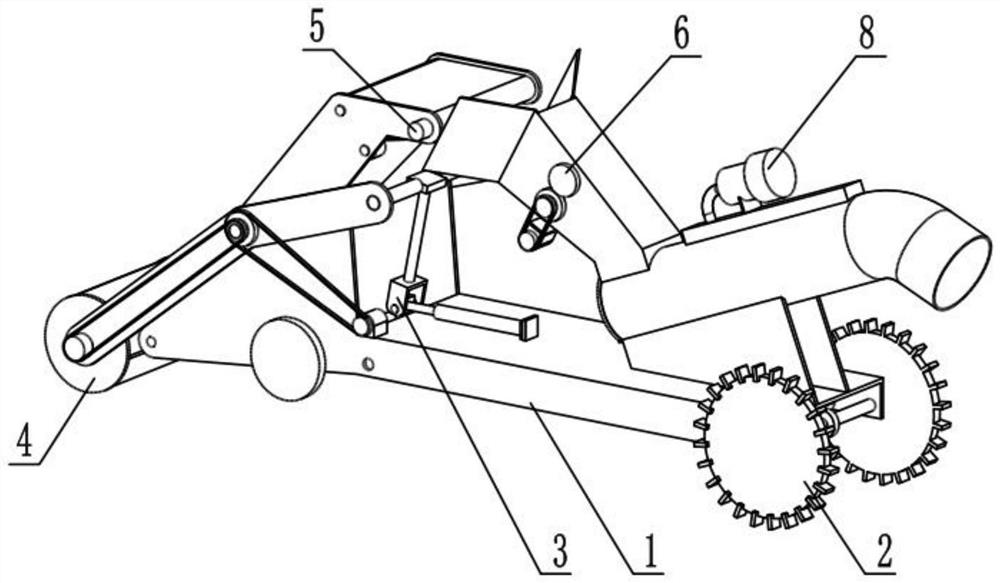

[0033] like Figure 1-11Shown, a kind of soil remediation governance system comprises mobile support 1, mobile mechanism 2, turret 3, digging mechanism 4, transportation mechanism 5, pulverizing mechanism 6, bulldozing mechanism 7 and volatile substance treatment device 8, described The moving mechanism 2 is rotatably connected to the rear end of the mobile bracket 1, the described turret 3 is rotatably connected to the front end of the mobile bracket 1, and the described earth-digging mechanism 4 is rotatably connected to the front end of the turret 3, and the earth-digging mechanism 4 and the mobile The support 1 is fixedly connected, the excavating mechanism 4 is rotatably connected to the turret 3, the transport mechanism 5 is rotatably connected to the mobile support 1, the crushing mechanism 6 is rotatably connected to the mobile support 1, and the bulldozing mechanism 7 Connected to the mobile support 1, the volatile substance processing device 8 is fixedly connected to...

specific Embodiment approach 2

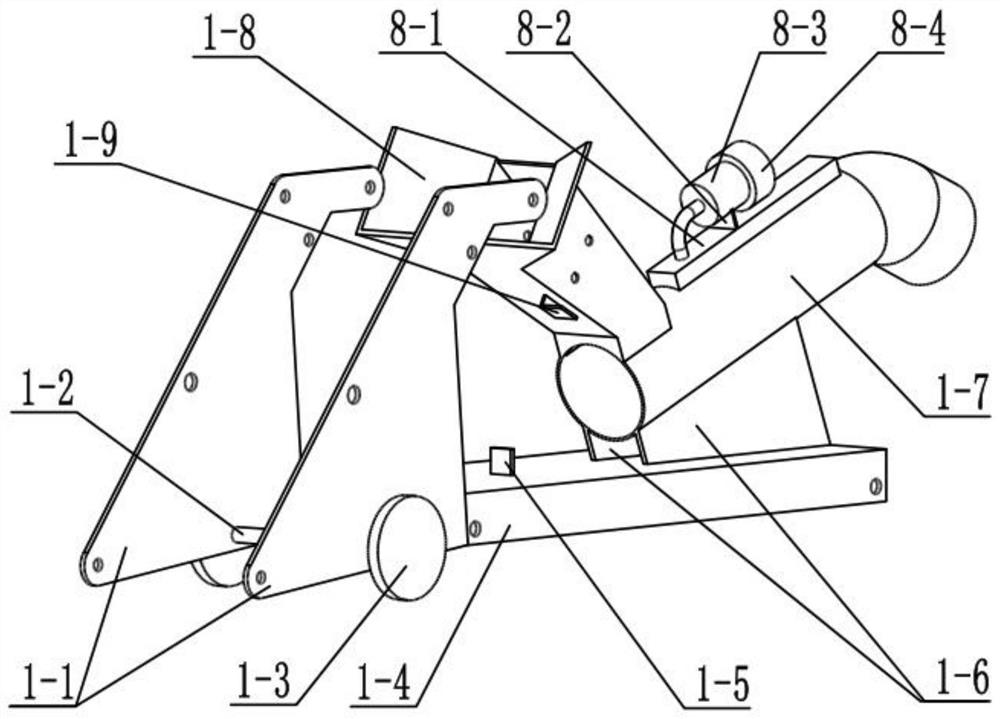

[0035] Such as Figure 1-11 As shown, the mobile support 1 includes a conveying support plate 1-1, a support shaft 1-2, a moving front wheel 1-3, a support base plate 1-4, a fixed plate 1-5, a connecting plate 1-6, a heating circle Pipe 1-7, crushing frame 1-8 and motor mounting plate 1-9, conveying support plate 1-1 is provided with two, and two conveying support plates 1-1 are all fixedly connected on the front end of support base plate 1-4, support The shaft 1-2 is fixedly connected to the two conveying support plates 1-1, the two ends of the support shaft 1-2 are connected to the moving front wheel 1-3 through bearing rotation, and the fixed plate 1-5 is fixedly connected to the support base plate 1- 4, two connecting plates 1-6 are provided, and the two connecting plates 1-6 are fixedly connected to the rear of the support base plate 1-4, and the heating round pipe 1-7 is fixedly connected to the two connecting plates 1 -6, the heating circular tube 1-7 is provided with ...

specific Embodiment approach 3

[0037] Such as Figure 1-11 As shown, the moving mechanism 2 includes a moving wheel 2-1, a moving shaft 2-2, a moving gear 2-3, a moving motor 2-4 and an anti-skid plate 2-5, and the moving shaft 2-2 is rotatably connected to the The rear end of the support base plate 1-4, the two ends of the moving shaft 2-2 are fixedly connected with moving wheels 2-1, and the two moving wheels 2-1 are provided with a plurality of anti-skid plates 2-5, and the moving shaft 2-2 2 is fixedly connected with a mobile gear 2-3, and the mobile motor 2-4 is fixedly connected to the support base plate 1-4, the mobile gear 2-3 and the mobile motor 2-4 are meshed and connected, and the mobile motor 2-4 is connected to the power supply through wires connected to the switch;

[0038] Start mobile motor 2-4, drive mobile gear 2-3, drive mobile wheel 2-1 to rotate by mobile shaft 2-2, make device move, antiskid plate 2-5 on the mobile wheel 2-1 can increase mobile wheel 2 -1 friction with the ground fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com