Automatic feeding machine and using method thereof

A technology of automatic feeding and driving motors, which is applied in the direction of conveyor objects, transportation and packaging, storage devices, etc., which can solve the problems of large space occupation and achieve the effects of improving work efficiency, reducing equipment size, and increasing work speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

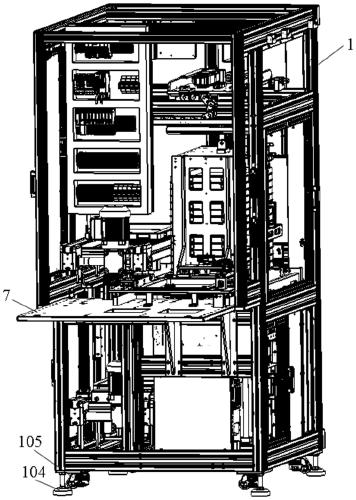

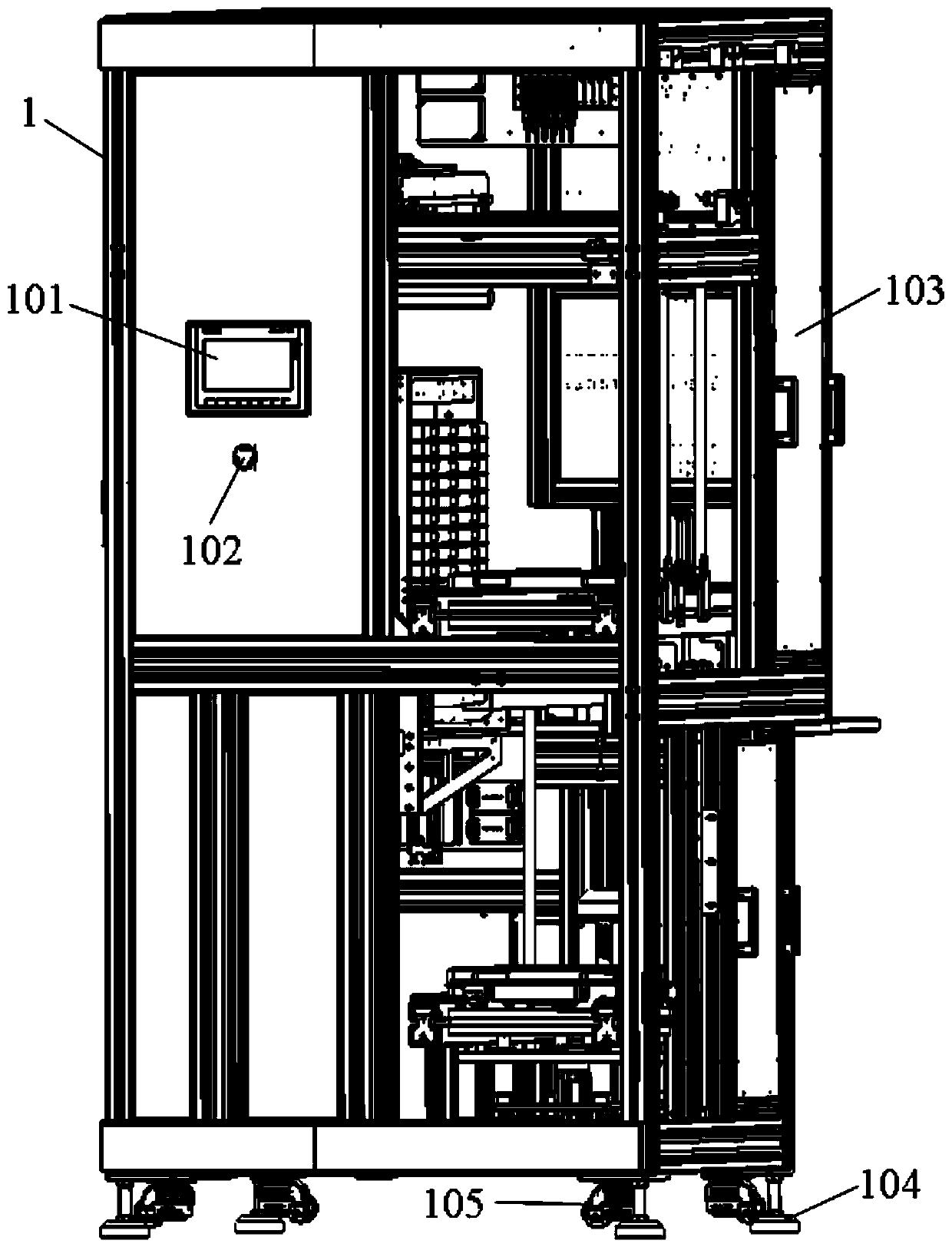

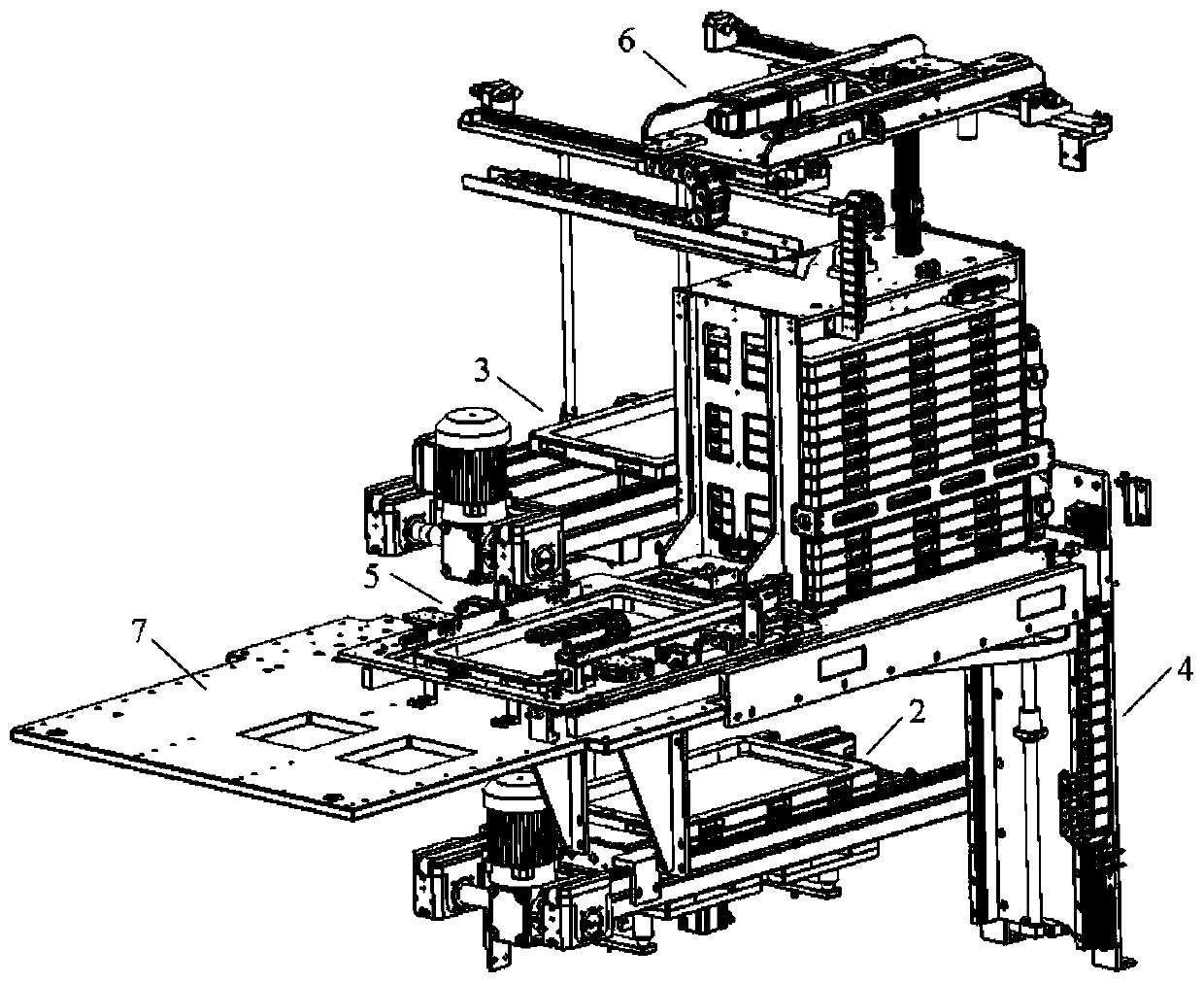

[0052] An automatic loading machine, comprising a chassis 1, a material feeding transmission line body 2, a material discharging transmission line body 3, a lifting component 4, a pushing and positioning component 5, a translation component 6, and a material retrieving platform 7.

[0053] as attached figure 1 and 2 As shown, the chassis 1 is provided with a touch screen 101 , an emergency stop button 102 , and a maintenance door 103 , and the lower end of the chassis 1 is provided with feet 104 and rollers 105 .

[0054] The feed transmission line body 2 , the discharge transmission line body 3 , the lifting assembly 4 , the translation assembly 6 , and the push positioning assembly 5 are all arranged in the cabinet 1 .

[0055] Further, a four-axis manipulator is arranged on the material reclaiming platform 7 , and the four-axis manipulator realizes the grabbing of materials on the material reclaiming platform 7 .

[0056] as attached image 3 and 4 As shown, the feed tr...

Embodiment 2

[0070] Based on above-mentioned embodiment 1, a kind of using method of automatic feeding machine comprises the following steps:

[0071] S1. Turn on the power supply, the full tray 8 is fed by the feed transmission line body 2, and is transferred to the lifting assembly 4 by the feed transmission line body 2.

[0072] The full tray 8 is transmitted via the feeding conveyor belt 202, and the first support frame 203 is pushed upward by the first cylinder 204, so that the full tray 8 is detached from the feeding conveyor belt 202, and then pushed by the second cylinder 206 to the lift assembly 4.

[0073] S2. After step S1, the full material tray 8 is moved upwards by the lifting component 4, and then transferred to the material picking platform 7 by the push positioning component 5 for material picking.

[0074] The full tray 8 is placed on the flat belt 407, the first servo motor 401 drives the screw 402 to rotate, and the connecting plate 404 drives the bracket 403 to move u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com