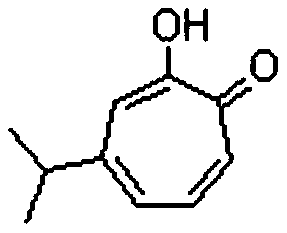

Efficient bacteriostatic and antibacterial soap stably containing hinokitiol derivative

A technology of hinoki alcohol and its derivatives, which is applied in the field of daily chemical cleaning products, can solve the problems of easy discoloration and yellowing of soap, and achieve the effects of low cost, high safety, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] components Composition (w / w) soap base 99.75% Hinokitiol Calcium Salt 0.25%

[0055] Add 300g of soap base into a glass beaker, place the beaker in a 65°C water bath, and after the soap base melts, turn on the cantilever stirring (r=300rpm / min), and stir for about 5 minutes to make the soap base evenly stirred. Weigh about 0.75 g of hinokitiol calcium salt, add it into the above stirring system, and continue stirring for about 10 min. Take the beaker out of the water bath, turn on the homogenizer (r=10000rpm / min), homogenize until the temperature of the soap liquid is about 50°C, and stop the homogenization. Put the soap liquid into the soap mold while it is hot, take it out after cooling and solidifying, put it in a 30% humidity environment and dry it in the dark for about 15 hours to get the finished soap.

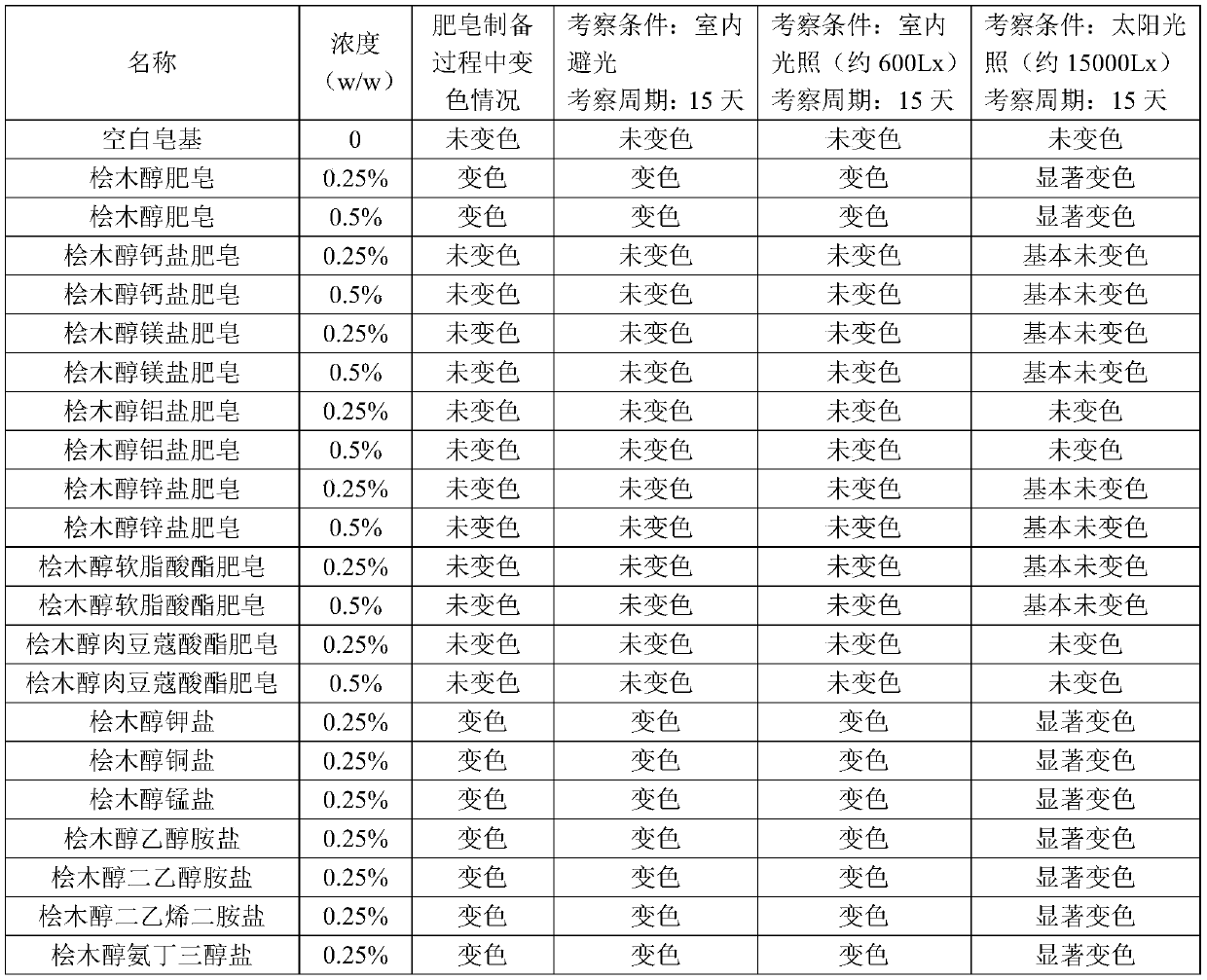

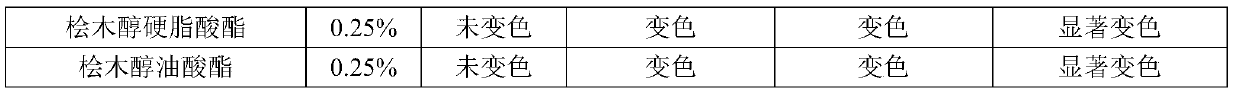

[0056] Table 1 Results of light discoloration during preparation and use of hinoki alcohol calcium salt soap

[0057]

Embodiment 2

[0059] components Composition (w / w) soap base 99.75% Magnesium hinokinol 0.25%

[0060] Add 300g of soap base into a glass beaker, place the beaker in a 65°C water bath, and after the soap base melts, turn on the cantilever stirring (r=300rpm / min), and stir for about 5 minutes to make the soap base evenly stirred. Weigh about 0.75 g of Hinokitiol magnesium salt, add it into the above stirring system, and continue stirring for about 10 min. Take the beaker out of the water bath, turn on the homogenizer (r=10000rpm / min), homogenize until the temperature of the soap liquid is about 50°C, and stop the homogenization. Put the soap liquid into the soap mold while it is hot, take it out after cooling and solidifying, put it in a 30% humidity environment and dry it in the dark for about 15 hours to get the finished soap.

[0061] Table 2 Results of light discoloration during preparation and use of hinoki alcohol magnesium salt soap

[0062]

Embodiment 3

[0064] components Composition (w / w) soap base 99.75% Aluminum salt of hinokinol 0.25%

[0065] Add 300g of soap base into a glass beaker, place the beaker in a 65°C water bath, and after the soap base melts, turn on the cantilever stirring (r=300rpm / min), and stir for about 5 minutes to make the soap base evenly stirred. Weigh about 0.75g of hinokitico aluminum salt, add it into the above stirring system, and continue stirring for about 10min. Take the beaker out of the water bath, turn on the homogenizer (r=10000rpm / min), homogenize until the temperature of the soap liquid is about 50°C, and stop the homogenization. Put the soap liquid into the soap mold while it is hot, take it out after cooling and solidifying, put it in a 30% humidity environment and dry it in the dark for about 15 hours to get the finished soap.

[0066] Table 3 Results of light discoloration during preparation and use of hinokiti alcohol aluminum salt soap

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com