A kind of pipe wall coating method

A coating and pipe wall technology, applied in the field of surface treatment of petroleum and mechanical engineering, can solve the problems of uneven corrosion degree, gas pipeline corrosion, uneven plating, etc., to improve the anti-corrosion ability, prolong the service life, targeted Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

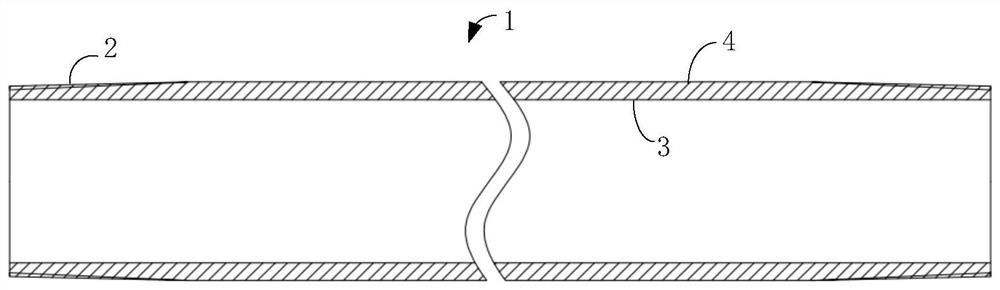

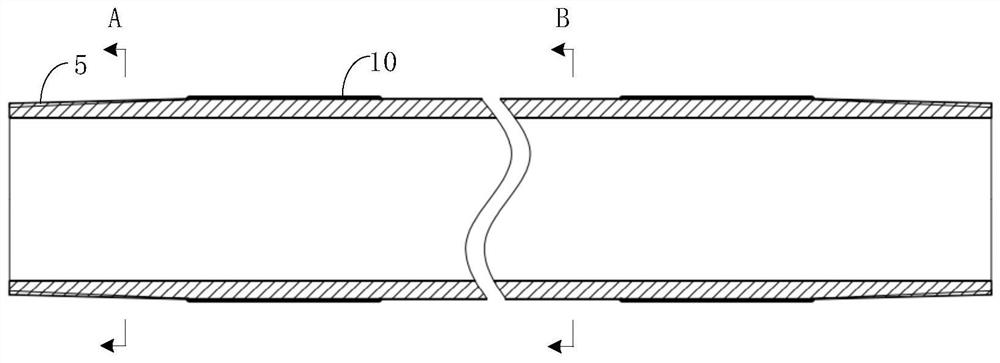

[0034] This embodiment provides a method for coating the walls of oil and casing pipes, such as figure 1 As shown, the pipe wall includes the inner wall 3 , the outer wall 4 and the screw thread 2 of the pipe body 1 . Electroplating is performed on the threaded button 2 , the inner wall 3 and the outer wall 4 respectively, including: threaded button electroplating, inner wall electroplating and outer wall electroplating. The thread button electroplating includes one or more steps of thread button high temperature degreasing, thread button chemical degreasing, thread button pickling, thread button activation and thread button electroplating process. The inner wall electroplating adopts the method of flow electroplating, and before the flow electroplating, it undergoes rust removal, oil removal, pickling, neutralization and activation in sequence. The outer wall electroplating includes the steps of rust removal on the outer wall, chemical degreasing by immersion, pickling by im...

Embodiment 2

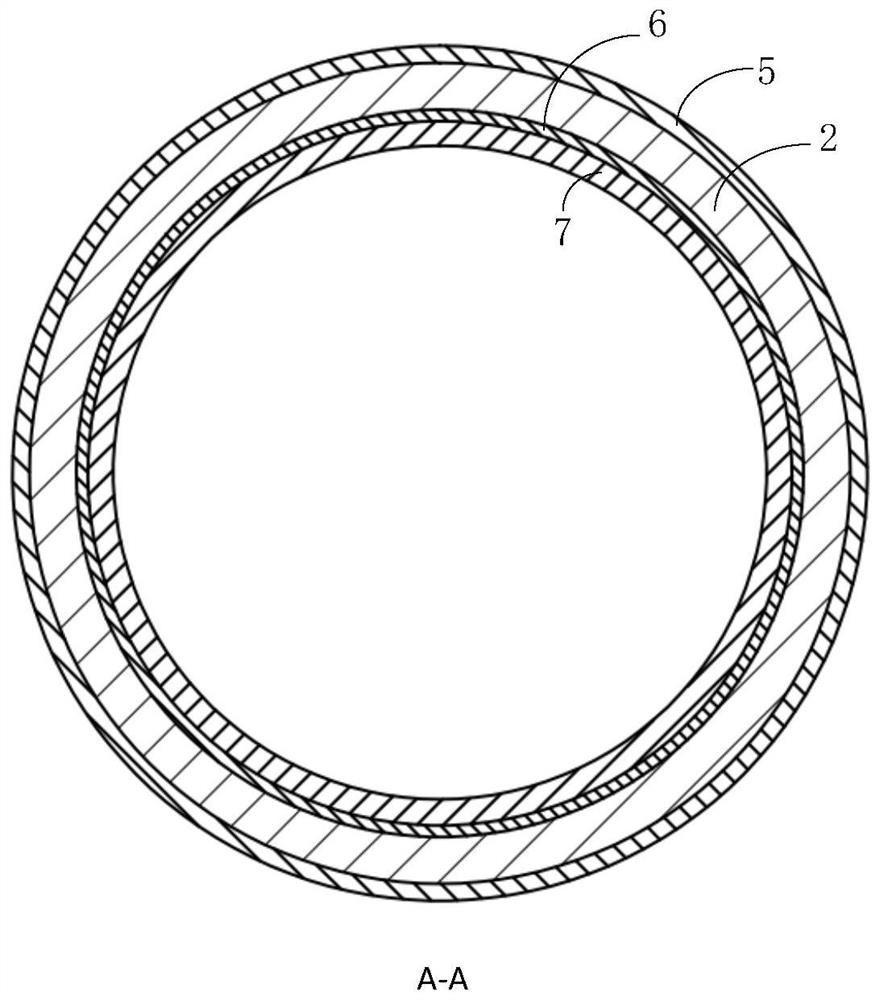

[0058] This embodiment is the pipe with anti-corrosion coating prepared by embodiment 1, such as figure 1 and figure 2 shown. The pipe with anti-corrosion coating includes a pipe body 1 and a threaded thread 2, and the inner wall 3 and the outer wall 4 of the threaded thread 2 and the pipe body 1 respectively have anti-corrosion coatings: namely, the threaded thread anti-corrosion coating 5, the inner wall anti-corrosion coating and the outer wall anti-corrosion plating.

[0059] The thread button anti-corrosion coating is metal nickel coating, and the thickness of the coating is 10 μm.

[0060] The anti-corrosion coating on the inner wall is a composite layer. From the inner wall to the outside, there are nickel coating 6 on the inner wall and nickel-tungsten-phosphorus coating 7 on the inner wall. The thickness of the composite layer is 60 μm.

[0061] The anti-corrosion coating on the outer wall is a composite layer, and from the outer wall to the outside, there are ni...

Embodiment 3

[0064] A well in Qinghai Oilfield is H 2 S is one of the more severely corroded wells. The sulfide content in the produced liquid is 20mg / L~45mg / L. On December 16, 2017, 3500 meters of pipes with anti-corrosion coating as shown in the application examples were compared with 100 meters of ordinary oil pipes. Well inspection on June 22, 2018 to prevent H 2 The S effect is obvious, and no corrosion damage occurs on the inner and outer walls, threads, and thickened sections. The expected effect was achieved. However, ordinary oil pipes are severely corroded in both the nozzle and the pipe body due to the influence of electrochemical corrosion and hydrogen-induced damage.

[0065] The invention has a perfect technological process, and performs comprehensive anti-corrosion on the inner and outer walls of the oil casing and threaded fasteners. High efficiency and strong anti-corrosion ability. Aiming at the corrosion of hydrogen sulfide, the invention completely prevents the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com