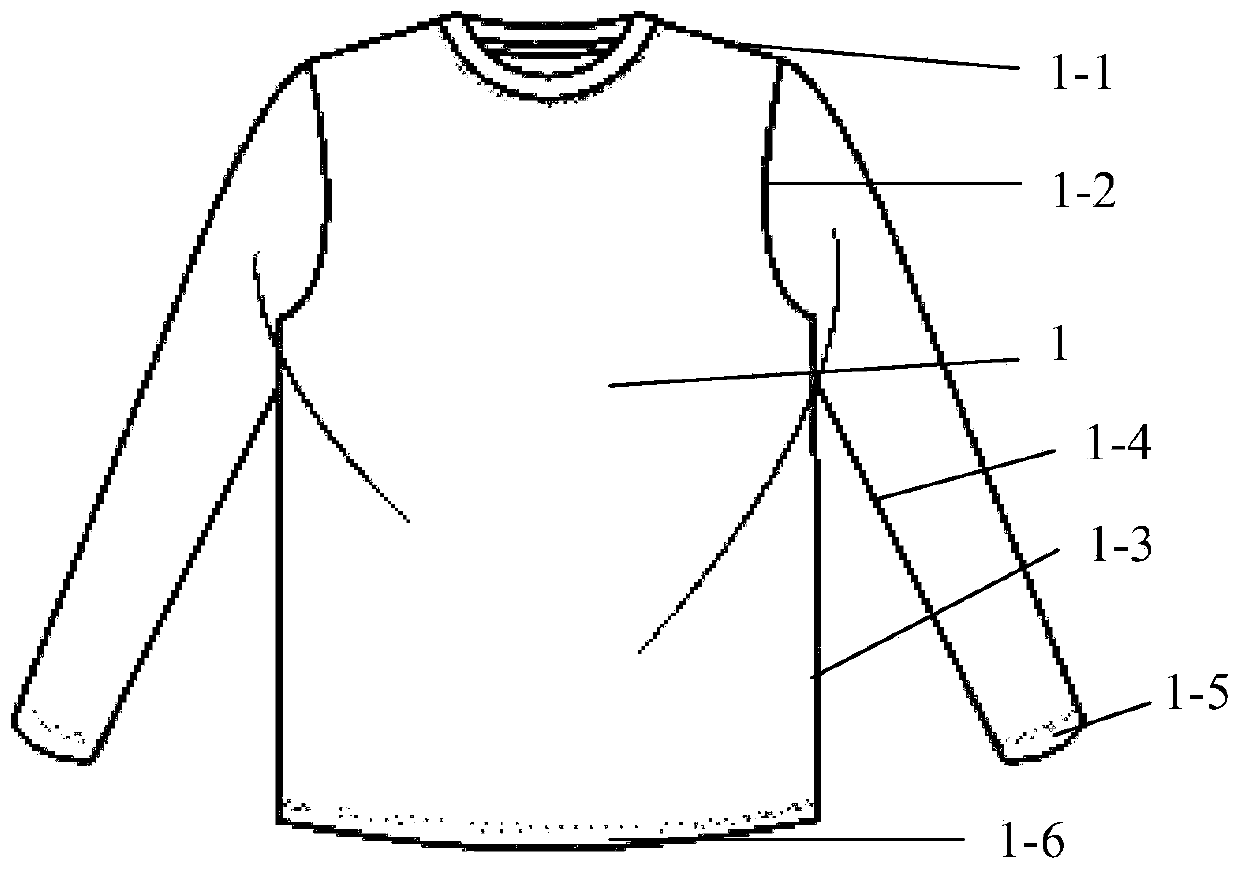

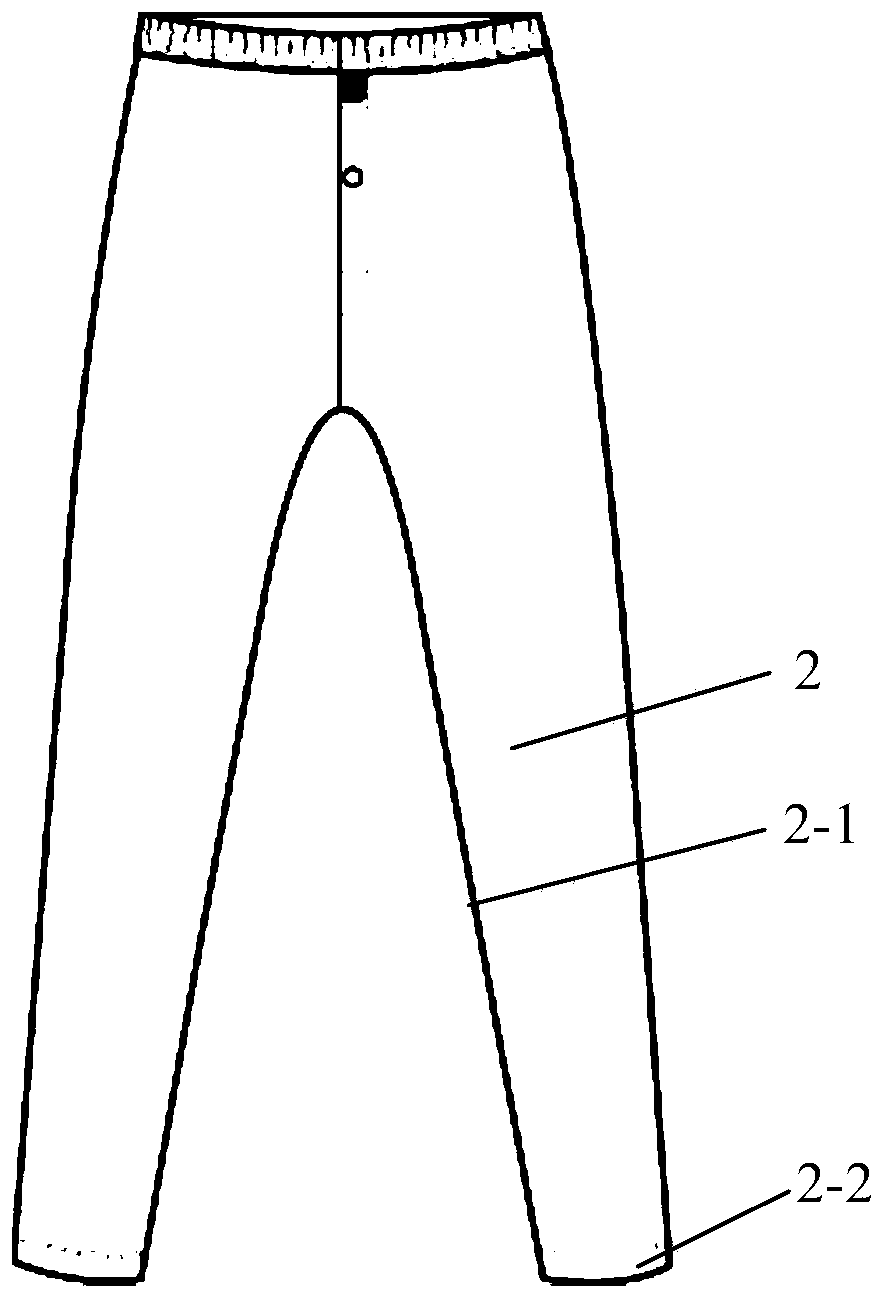

Super-soft heating red-bean-velvet underwear fabric and suit

A technology of underwear fabric and red bean velvet, which is applied in the directions of underwear, baby underwear, and cashmere, can solve the problems of uncomfortable wearing, non-soft cotton underwear, itchiness, etc., and achieve the effect of comfortable wearing and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

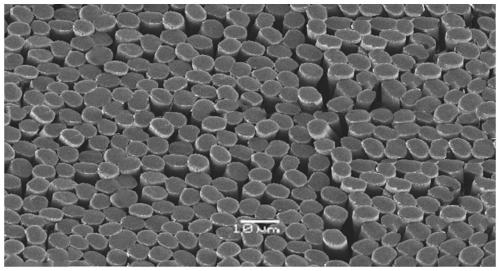

[0028] An ultra-soft and wind-heating red bean velvet underwear fabric, the fabric is a single-sided weft-knitted structure, woven from high-count blended yarn and spandex, and the fabric weight is 155g / m 2 , by mass fraction, the blended yarn includes 45% Lenzing Modal, 30% Australian cotton and 25% superfine soft acrylic fiber.

[0029] The acrylic fiber has a linear density of 0.56D and a fineness of 6.1 μm.

[0030] The length of the cotton fiber is 29 mm, the specific strength is 32 cN / tex, and the micronaire value is 4.

[0031] The Lenzing Modal has a linear density of 1.6dtex, a length of 40mm, and a moisture regain of 10%. The winding and warping process adopts an automatic warping machine, a metal groove drum, and is equipped with an electric blue and air splicer to realize knot-free yarn. When sizing Adding polyvinyl alcohol and propylene pulp, the process should adopt light pressure, stretch protection, strict control of tension, single immersion and single pressu...

Embodiment 2

[0043] An ultra-soft and wind-heating red bean velvet underwear fabric, the fabric is a single-sided weft-knitted structure, woven from high-count blended yarn and spandex, and the fabric weight is 155g / m 2 , by mass fraction, the blended yarn includes 45% Lenzing Modal, 30% Australian cotton and 25% superfine soft acrylic fiber.

[0044] The acrylic fiber has a linear density of 0.6D and a fineness of 6.4 μm.

[0045] The length of the cotton fiber is 30 mm, the specific strength is 30 cN / tex, and the micronaire value is 4.

[0046] The Lenzing Modal has a linear density of 1.8dtex, a length of 38mm, and a moisture regain of 10%. The winding and warping process adopts an automatic warping machine, a metal groove drum, and is equipped with an electric blue and air splicer to realize knot-free yarn. When sizing Adding polyvinyl alcohol and propylene pulp, the process should adopt light pressure, stretch protection, strict control of tension, single immersion and single pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com