A construction method for super long side span straight section of high pier PC bridge with corrugated steel web

A technology of corrugated steel webs and construction methods, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as low construction efficiency, large material investment, and difficulty in establishing support systems, so as to improve construction efficiency and reduce consumption , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

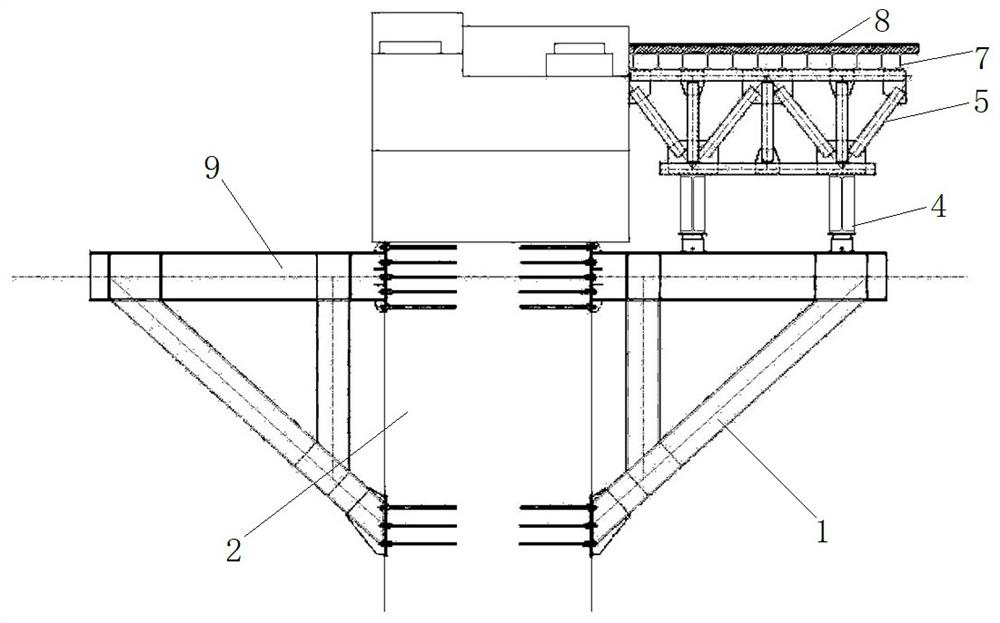

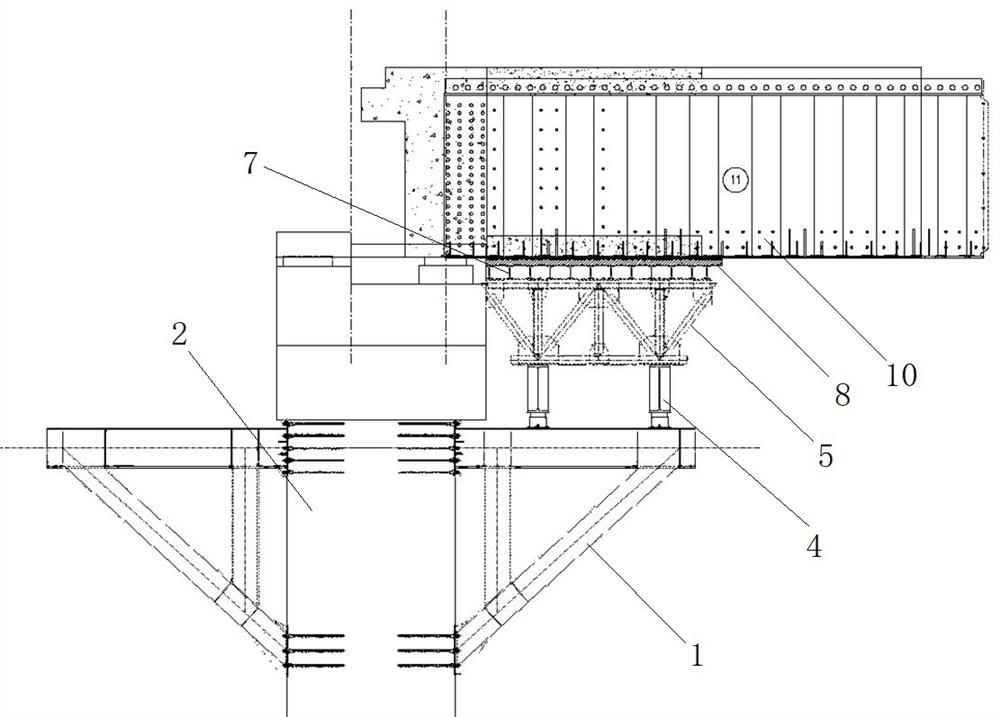

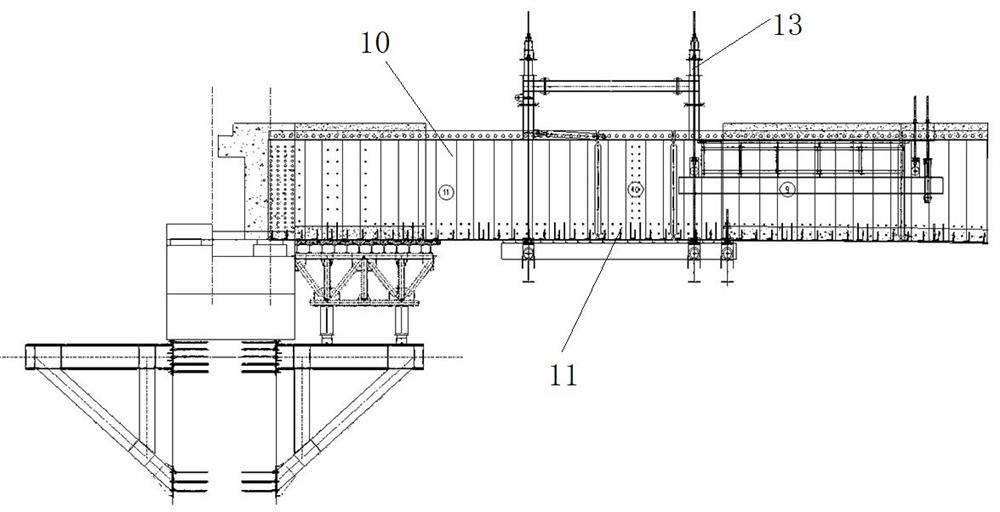

[0025] The present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0026] The embodiment of the construction method of the super-long side span straight section of the high pier of the corrugated steel web PC bridge of the present invention:

[0027] The construction method of the straight section of the high pier and the super long side span of the PC bridge with corrugated steel web mainly includes the following steps:

[0028] Step 1: Bracket installation: It mainly includes dividing the straight line section of the side span to be constructed into two construction sections longitudinally, pre-embedding the brackets symmetrically on both sides of the side pier, and preloading the brackets symmetrically. As the support platform for the first construction section;

[0029] Step 2: Cast-in-place construction of the first side span: mainly includes installing the side-span cast-in-place corrugated steel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com