Rubber cleaning equipment for airport runway

An airport and rubber technology, which is applied in the field of airport runway rubber cleaning equipment, can solve the problems of difficulty in recovery, damage to the engine, and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

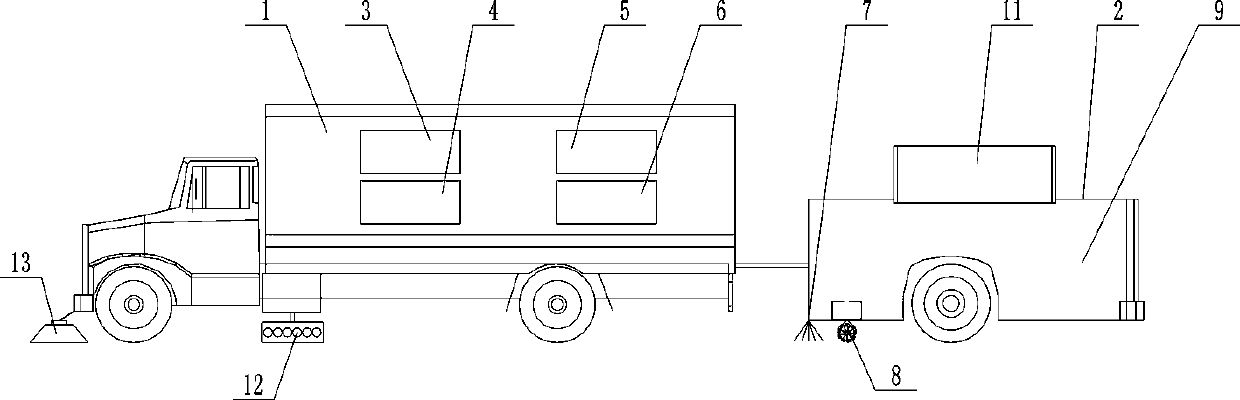

[0030] Such as figure 1 As shown, a rubber cleaning equipment for an airport runway includes a carrier vehicle 1, a trailer 2, a control center 3 installed in the carrier vehicle 1, an ion generator 4, an air separator 5, a generator 6 and a vehicle installed at the bottom of the trailer 2 The ion jet injection device 7 at the end, the dust collection device 8 and the dust box 9 inside the trailer 2, the control center includes two parts, the main control and calculation part is the control center 3, located in the carrier vehicle 1, the ion jet injection device 7, The controller 11 of the dust collection device 8 is located on the trailer 2, and acts in conjunction to control the operation of the ion generator 4, the air separator 5 and the ion jet injection device 7, and the generator 6 supplies power for the entire equipment, because each element There is only a connection relationship or an electrical signal transmission relationship between devices, and there is no specif...

Embodiment 2

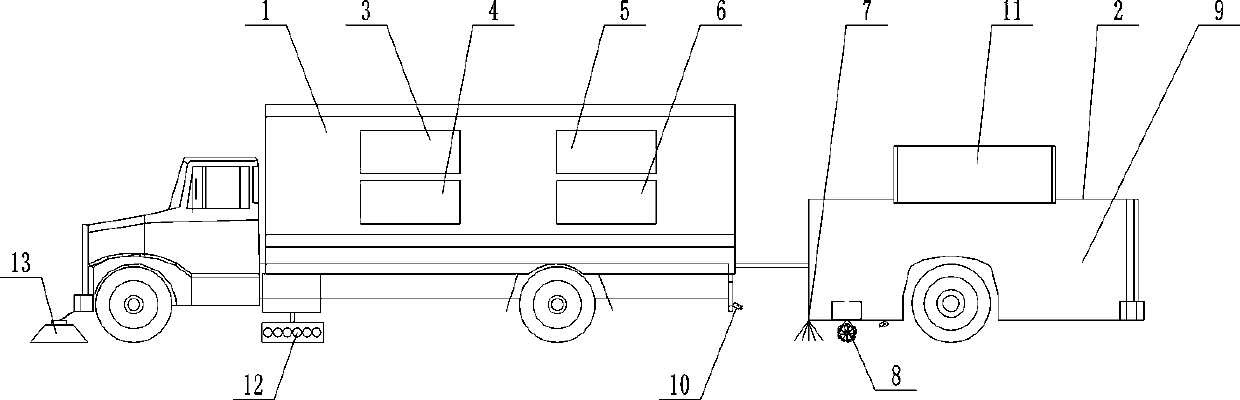

[0039] Such as figure 2 As shown, in order to improve the degree of automation, a video camera 10 is installed at the bottom of the car body, and the video camera 10 is distributed on the front and rear sides of the ion jet injection device. The video camera 10 is connected to the control center 3 for collecting road surface rubber images .

[0040]After analyzing the collected image information, for example, the following situations are obtained: no rubber layer on the road surface, a small amount of rubber layer on the road surface, and a large amount of rubber layer on the road surface. After obtaining these information, the control center 3 adjusts the ion The flow rate of the jet injection device, the efficiency of the air separator and the ionizer.

[0041] In other embodiments, in order to facilitate the walking of the vehicle while ensuring the effectiveness of the jet, the ion jet injection device can be installed on the vehicle body through an electronically contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com