Water-saving pedestal pan

A toilet and sinking technology, which is applied in the field of bathroom, can solve the problems of poor brushing and spraying effect, loss of conduction kinetic energy of flushing water, and inability to distribute water to the toilet, and achieves good water saving effect, enhanced washing effect, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

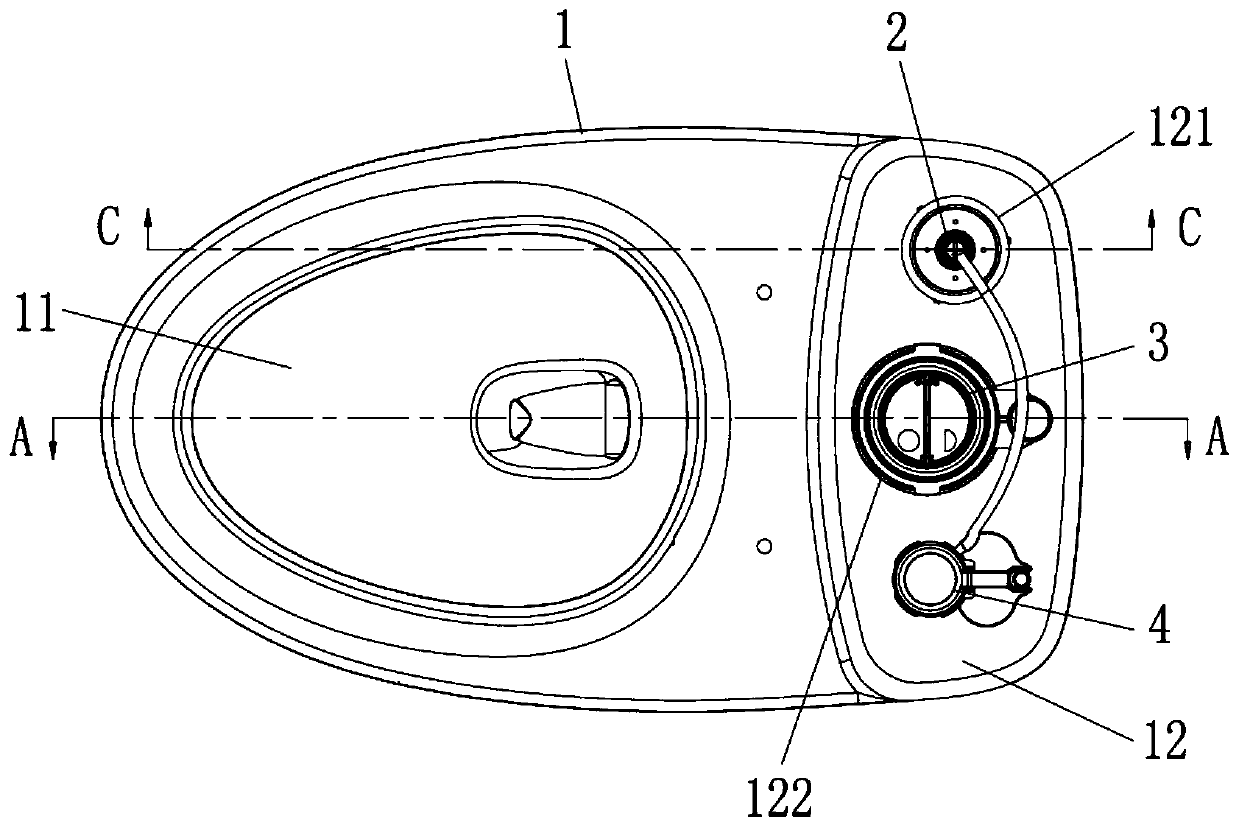

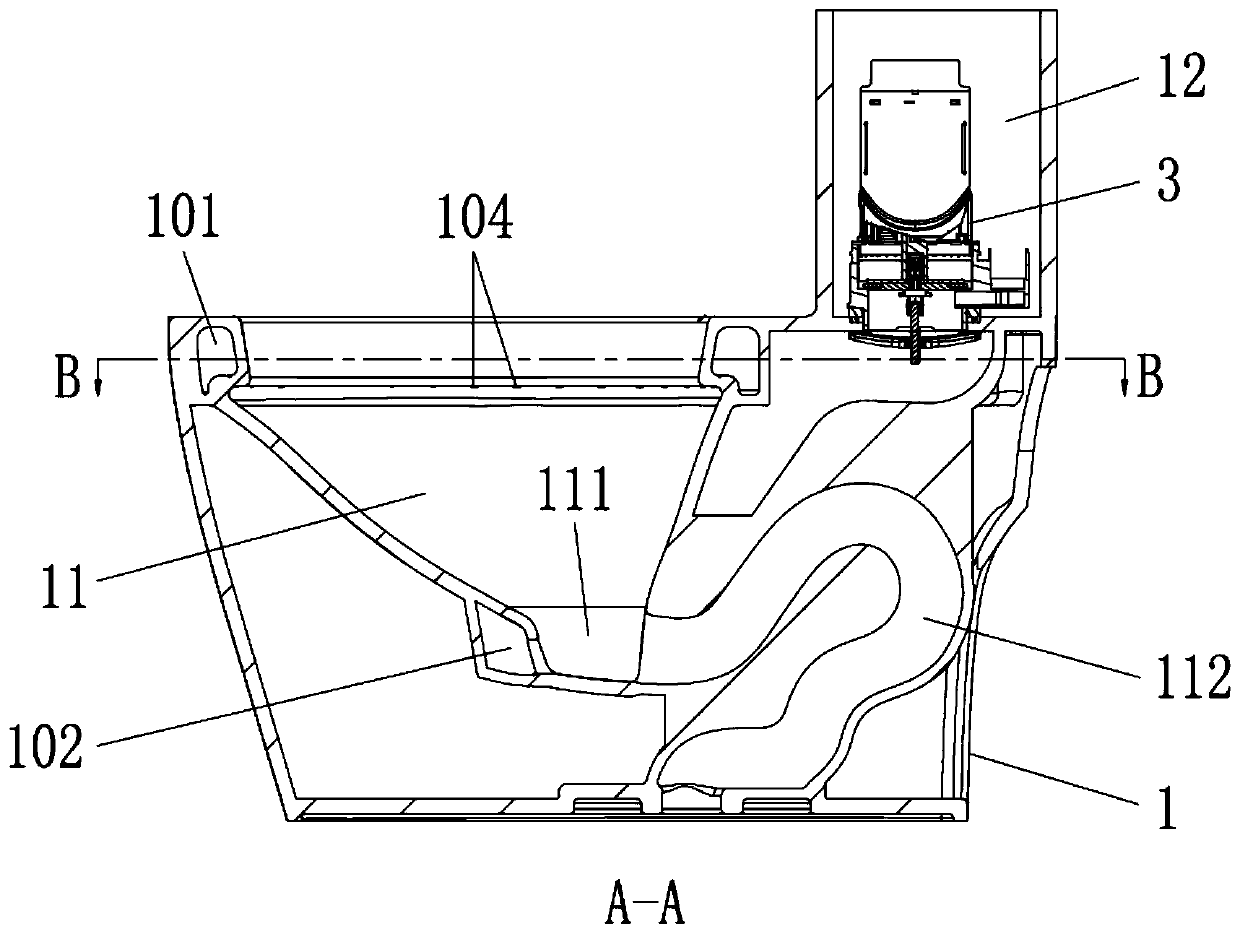

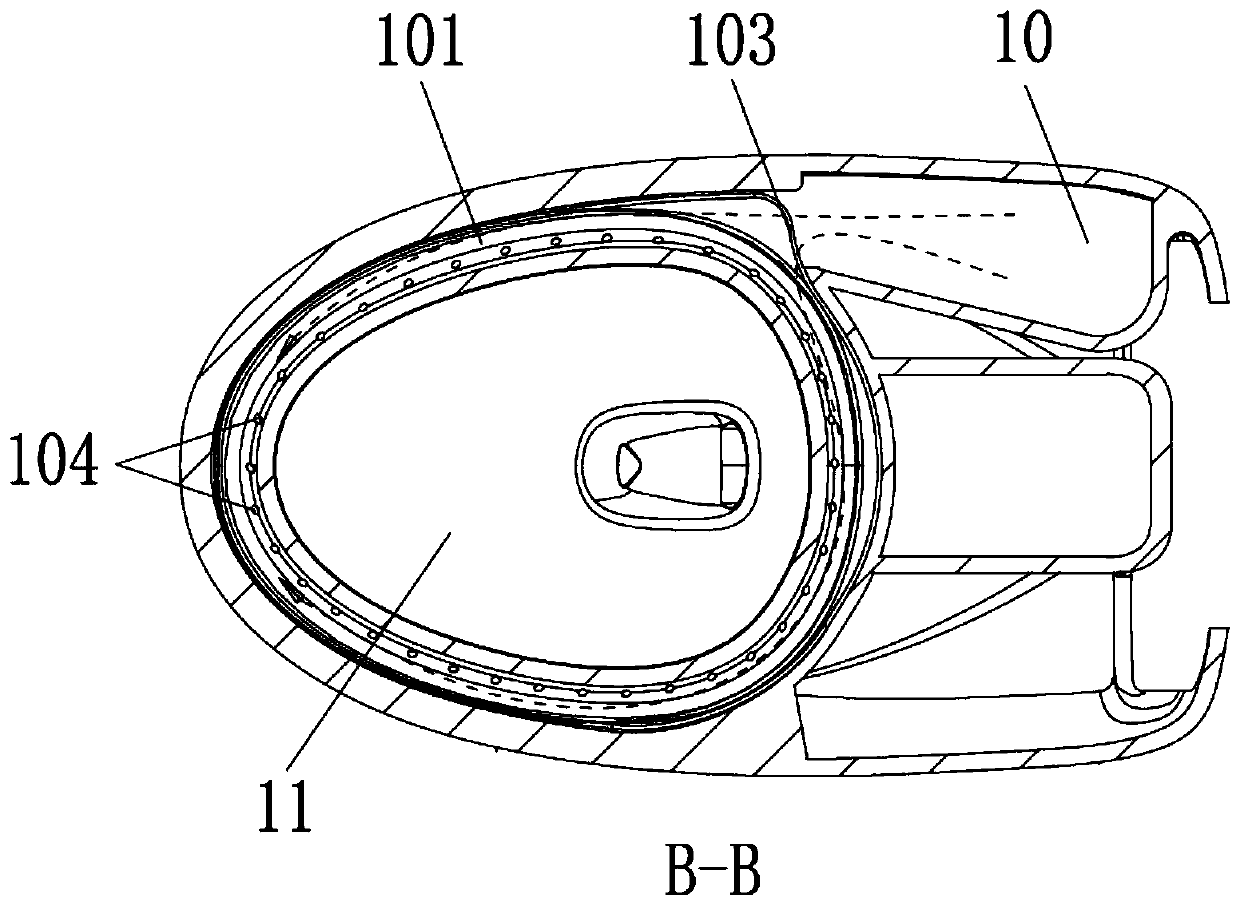

[0060] Such as Figure 1-4 As shown, a water-saving toilet includes a toilet body 1, a toilet 11 and a water storage tank 12 are arranged on the toilet body 1, a sinking bay 111 is provided at the bottom of the sinking 11, and the sinking bay 111 is connected with Sewage siphon 112. The inside of the toilet body 1 is provided with a scrubbing water delivery pipeline 101 for flushing the surrounding wall of the urinal 11 and a spray water delivery pipeline 102 for flushing the bottom of the cesspool 11, and the scrubbing water delivery pipeline 101 and the jet water delivery pipeline The pipes 102 are arranged independently of each other. The bottom of the water storage tank 12 is provided with a first installation hole 121 and a second installation hole 122 respectively, the first drainage valve 2 is installed in the first installation hole 121, the second drainage valve 3 is installed in the second installation hole 122, and the second drainage valve 3 is installed in the se...

Embodiment 2

[0078] Such as Figure 23-27 As shown, the difference between the present embodiment and the first embodiment is only that the brushing water delivery pipeline 101 is an annular water diversion tank with side openings, and the two sides of the transition water chamber 10 are respectively provided with a first channel connected with the annular water diversion tank. The direction of the swirl injection port 105 and the second swirl injection port 106, the first swirl injection port 105 and the second swirl injection port 106 are all the same as the flow direction of the flushing water of the annular water diversion tank. The rest of the structure of this embodiment is the same as that of Embodiment 1.

[0079] After the second drain valve 3 is opened, the water in the water storage tank 12 flows into the jetting water delivery pipeline 102 through the second installation port 122 to flush the bottom of the urinal 11 . When the water level drops to a certain height, the first d...

Embodiment 3

[0081] Such as Figure 28-30 As shown, the difference between this embodiment and the first embodiment is only that the first drain valve 2 and the second drain valve 3 are flap-type drain valves. The top of the first drain valve 2 is provided with a first chain 209 for driving it to open, and the top of the second drain valve 3 is provided with a second chain 300 for driving it to open. The tops of the first hanging chain 209 and the second hanging chain 300 are respectively connected with the connecting rod 61, and the side of the toilet body 1 is provided with the connecting rod 61 and is used to drive the connecting rod 61 to rotate to open the first drain valve 2 and the second connecting rod. The wrench 62 of the second drain valve 3. An overflow pipe 29 communicating with the transition water chamber 10 is installed on the top of the first drain valve 2 . The rest of the structure of this embodiment is the same as that of Embodiment 1.

[0082] In this implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com