Downhole tubing and sucker rod heating device

A technology for heating devices and sucker rods, applied in the direction of isolation devices, drill pipes, drill pipes, etc., can solve the problem of high power consumption, achieve the effects of reduced power consumption, shortened contact time, and reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

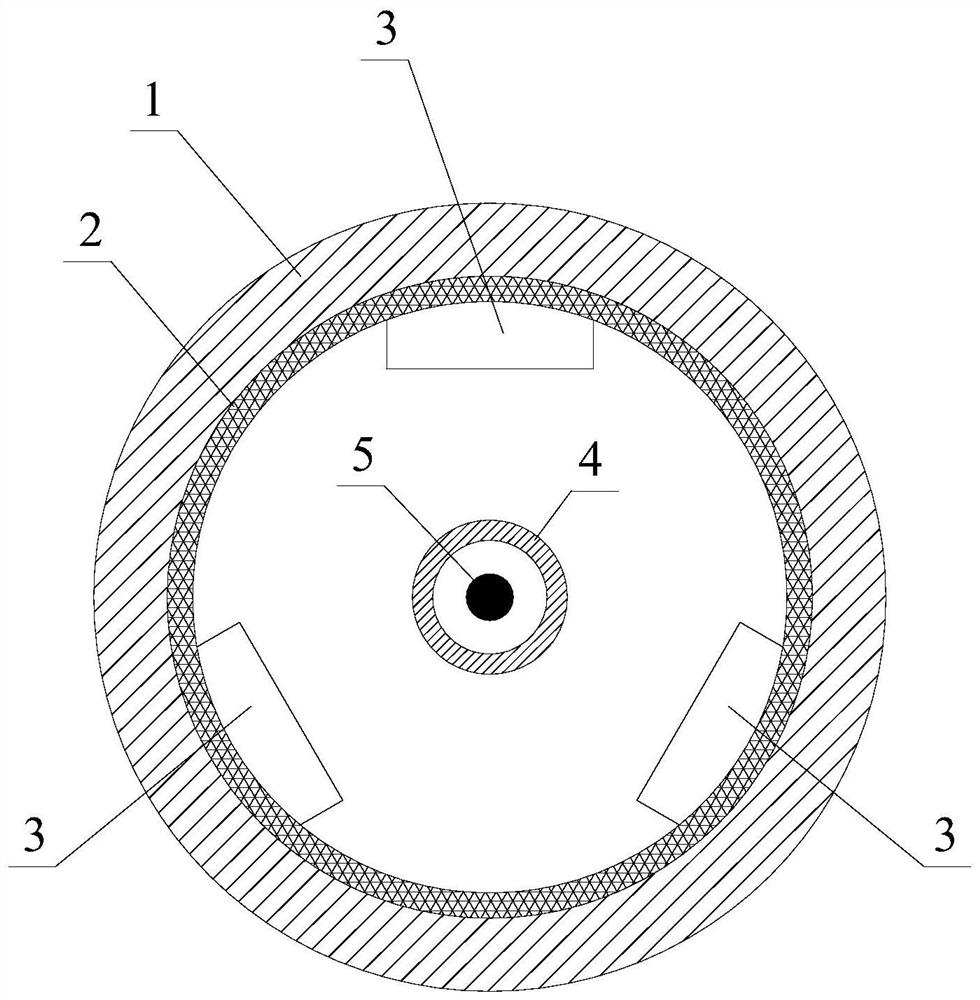

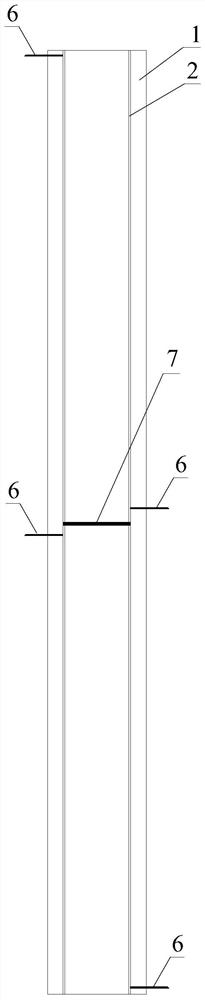

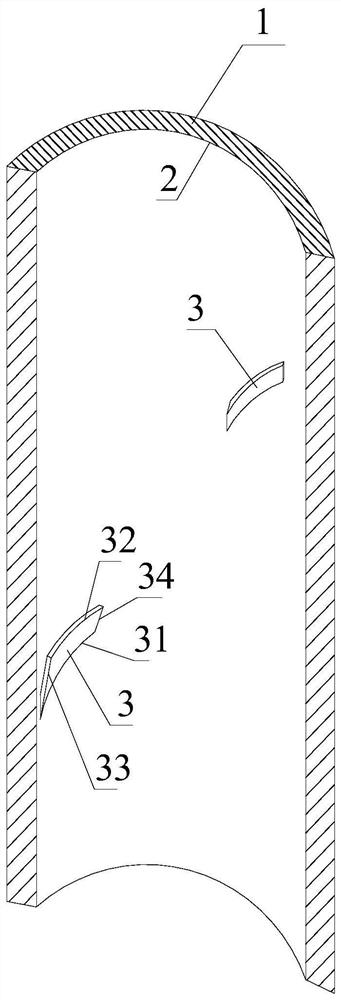

[0035] The downhole oil pipe and sucker rod heating device provided in this embodiment uses an intermediate frequency heating power supply and an intermediate frequency transformer to provide intermediate frequency current to the sucker rod 4 and the internal cable 5. In order to increase the heating temperature, the cable in the hollow sucker rod can use Skin heating cables. On this basis, improvements are made to the inner wall of the oil pipe. like figure 1 As shown, the oil pipe 1 in this embodiment is made of insulating material, and a metal layer is arranged on the inner wall of the oil pipe 1, which is called the first metal layer 2. The first metal layer 2 can be a thin metal plate, or it can be attached to the oil pipe. 1 For the metal film on the inner wall, there is no restriction on which metal to use, and it can be selected according to the actual situation. In principle, try to choose a material that generates a large amount of heat after electrification. For e...

specific Embodiment approach 2

[0042] On the basis of Embodiment 1, the downhole tubing and sucker rod heating device described in this embodiment also adds automatic control equipment, and its structure is as follows Figure 4 shown. There is a circuit breaker connected in series between the electrical parameter collector and the three-phase power supply, and the three-phase power is input to the intermediate frequency heating power supply after passing through the electrical parameter collector, and the three-phase electrical signals collected by the electrical parameter collector are sent to the signal control processor through the 485 bus , the intermediate frequency heating power supply processes the input three-phase electricity and then outputs two-phase intermediate frequency electrical signals to the intermediate frequency transformer. The intermediate frequency transformer isolates and transforms the input two-phase electrical signals, and the transformed electrical signals are used as loads (R1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com