Servo control system for automatic bagged cement loading robot

A servo control system, robot technology, applied in electric speed/acceleration control, transportation and packaging, stacking of objects, etc., to achieve high loading efficiency, remarkable effect, and high positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

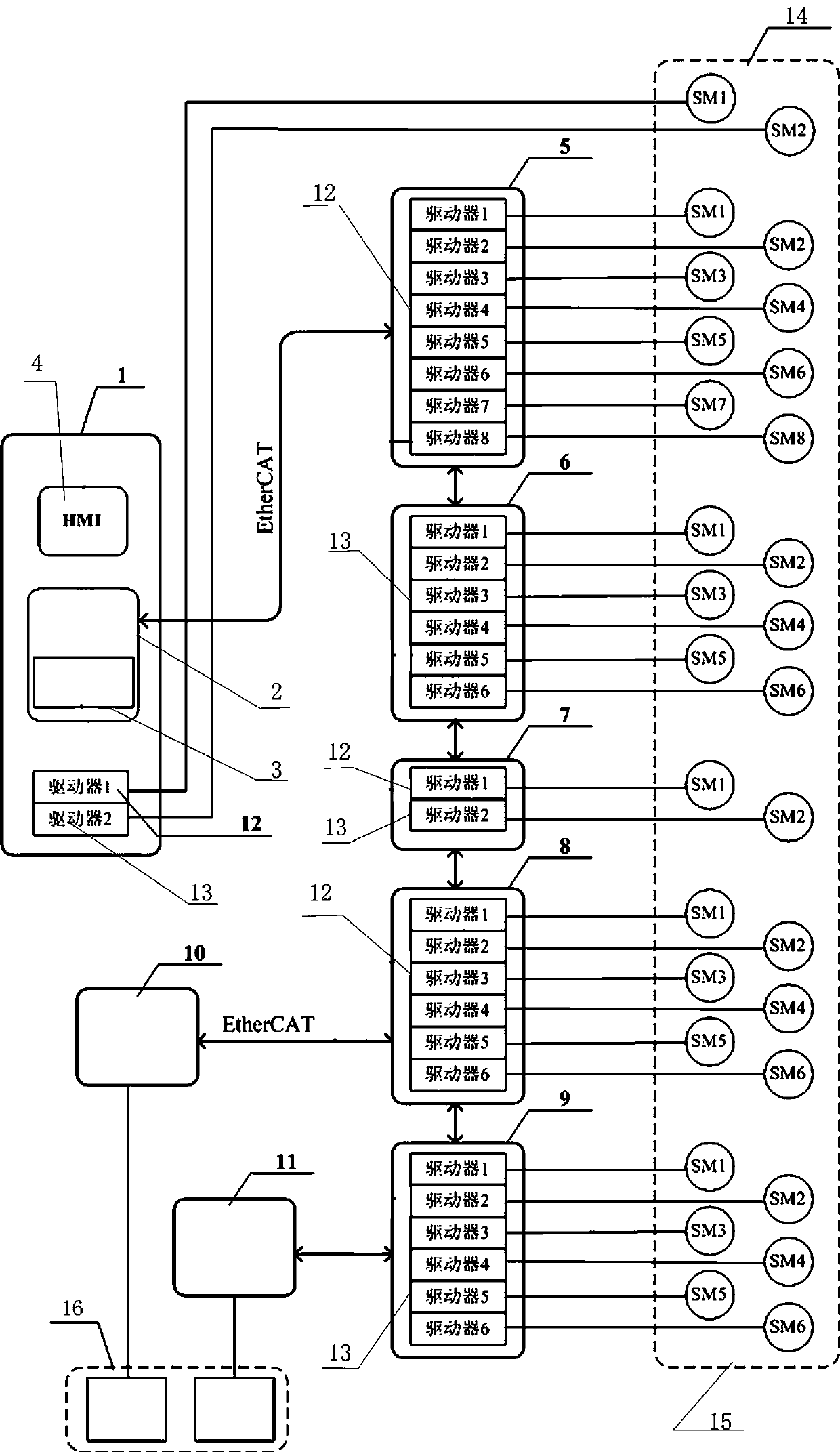

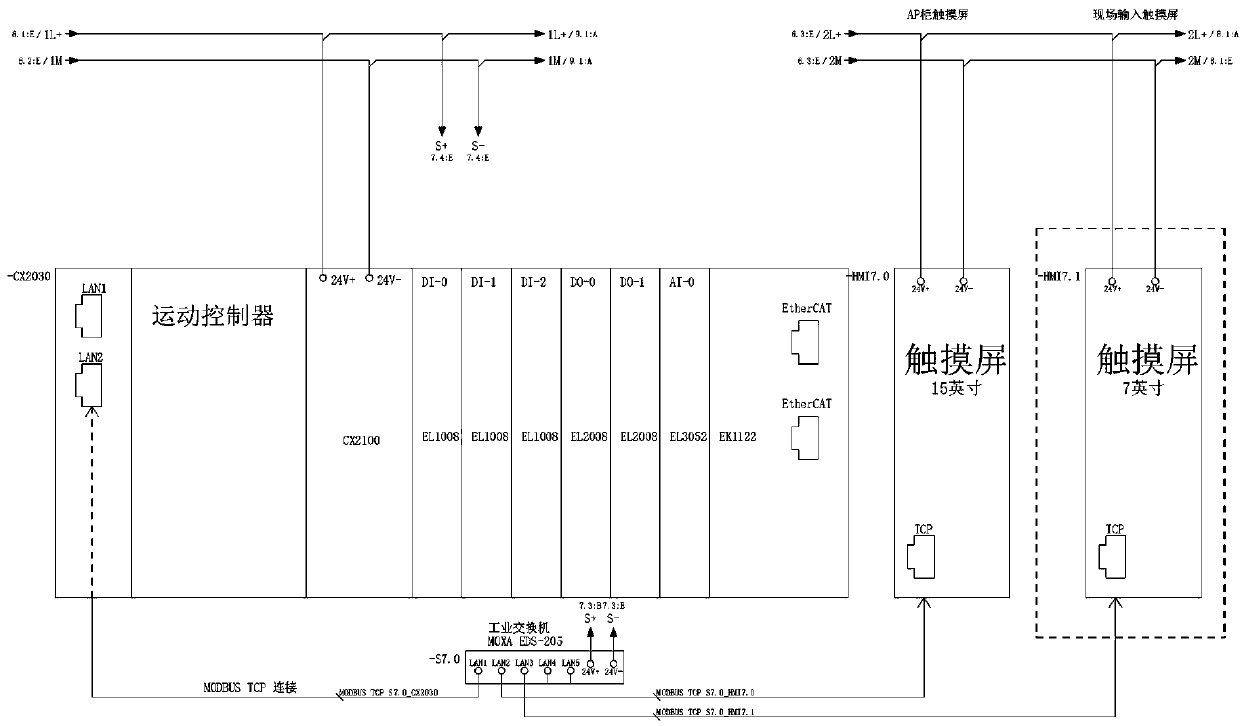

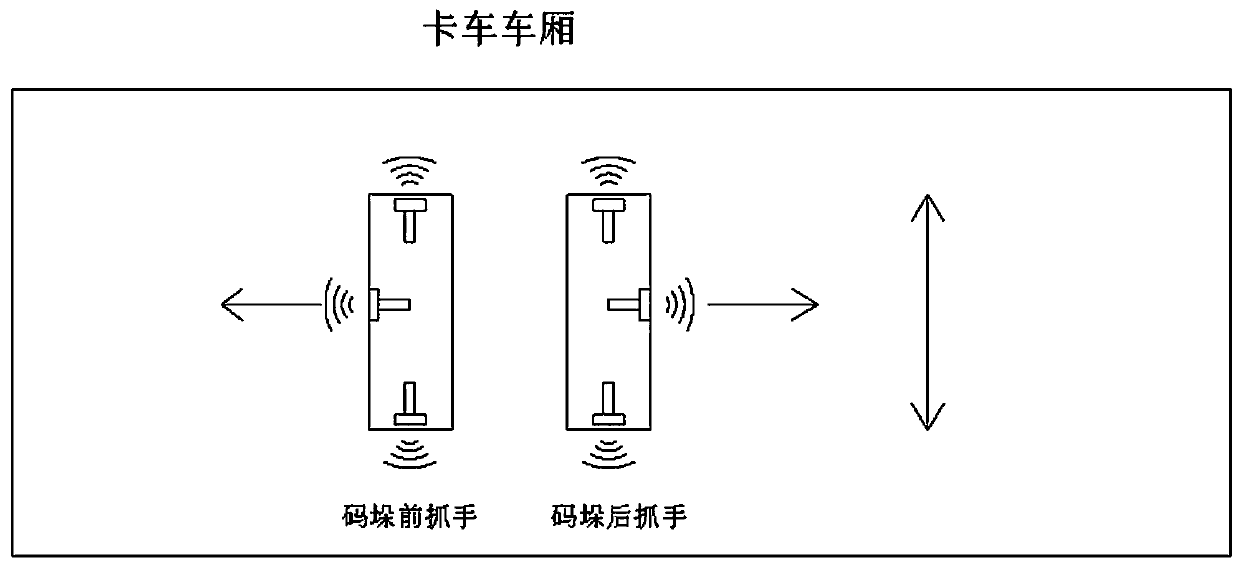

[0031] A robot servo control system for automatic loading of bagged cement, including a stacking robot with a large truss, two sets of monolithic platforms, and two sets of grab buckets, and a servo control system that cooperates with the stacking robot. The system includes main power supply cabinet 1, main controller 2, man-machine interface HMI4, electric control cabinet 5 for the first cart, electric control cabinet 6 for the second cart, electric control cabinet 7 for the base of the cart, and electric control cabinet 8 for the first cart , the second trolley electric control cabinet 9, the first trolley expansion box 10, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com