Ductile cast iron pipe spraying device capable of automatic positioning and 360-degree adjustment

A nodular cast iron, automatic positioning technology, applied in the direction of the spraying device, can solve the problems of uneven spraying thickness, uneven spraying, harmful gas environmental pollution, etc., and achieve the effect of increasing the contact area, improving production efficiency, and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

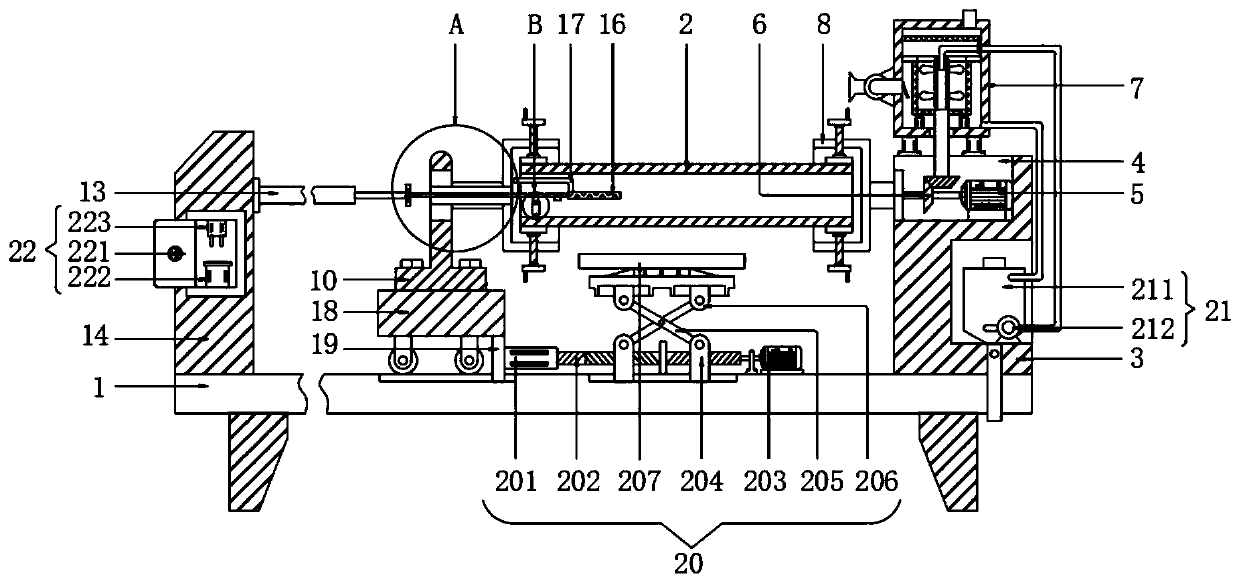

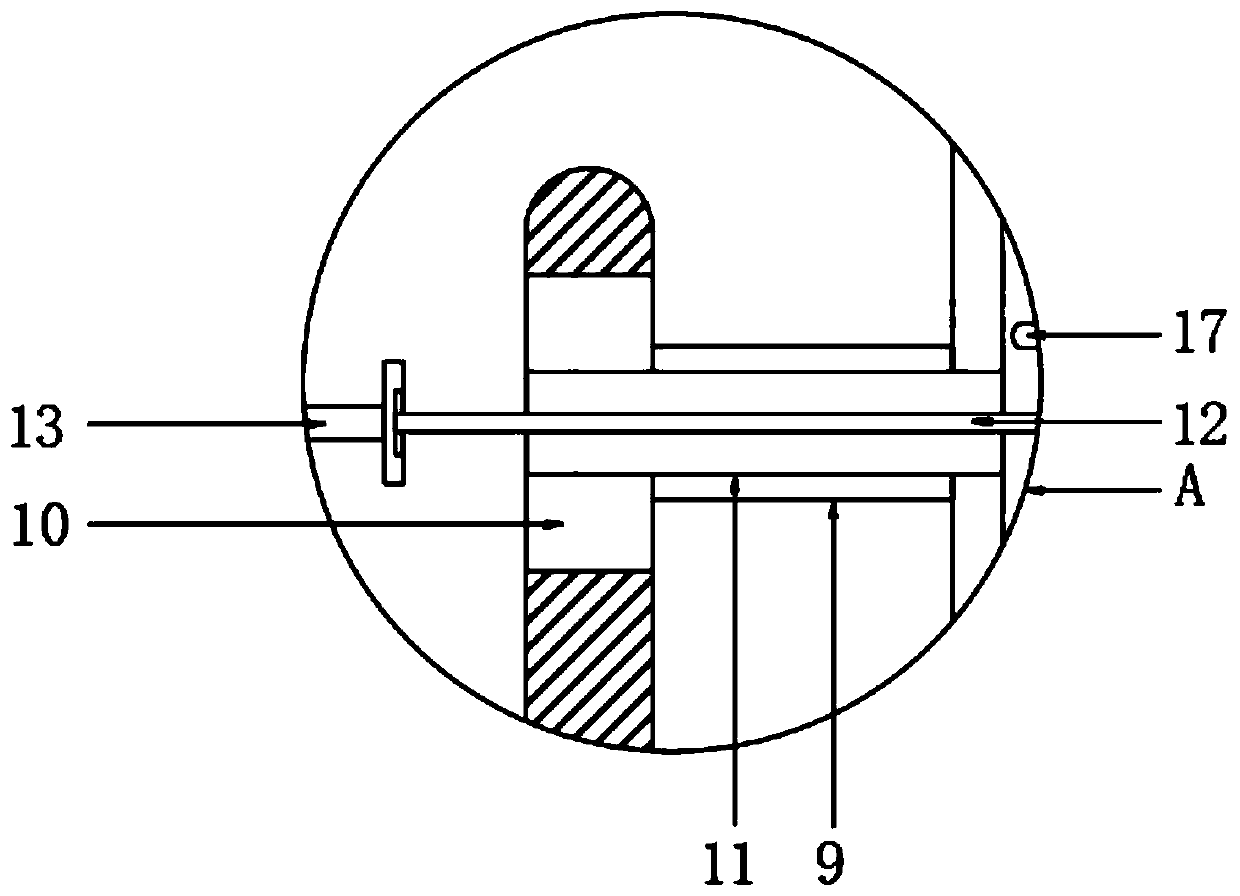

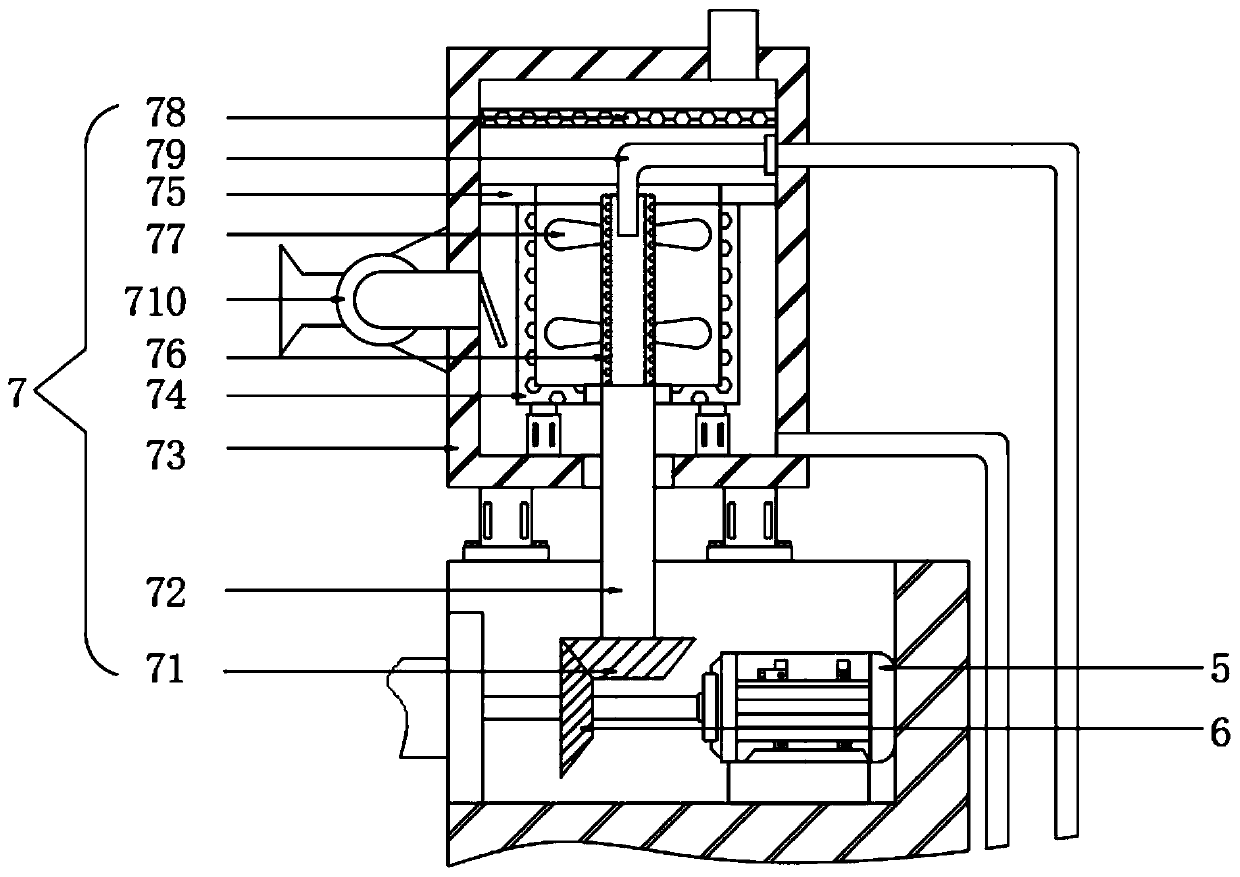

[0026] The present invention provides a technical scheme: a spraying device for ductile iron pipes that can be automatically positioned and adjusted 360 degrees, please refer to figure 1 with figure 2 , Including a base 1 and a ductile iron pipe body 2, a fixing base 3 is welded on the top right side of the base 1, a groove 4 is provided on the top of the fixing base 3, and a first motor 5 is fixedly connected in the groove 4, and the first motor The driving wheel 6 is sleeved on the power shaft of 5, the first motor 5 is connected to the power shaft through a reducer, and the speed of the power shaft can be adjusted. The top of the driving wheel 6 is connected with the purification assembly 7, and the two ends of the ductile iron pipe body 2 Both are movably connected with a clamping assembly 8. The clamping assembly 8 is used to fix the ductile iron pipe body 2. For those skilled in the art, it is the prior art. The two sets of clamping assemblies 8 are fixedly connected on th...

Embodiment 2

[0036] See Image 6 The difference from implementation 1 is that the anti-loosening component 156 includes anti-loosing plates 1561 movably connected to both sides of the knob 155, and rubber pads are filled between the anti-loosing plate 1561 and the knob 155, which can improve the anti-slip effect. The anti-loosing plate 1561 There is also a pull block for pulling the anti-loosing plate 1561. The two sets of anti-loosing plates 1561 are provided with a fixing block 1562 at the ends away from each other. The fixing block 1562 is provided with a support spring 1563. The two sets of support springs 1563 are far away from each other. One end is provided with a support block 1564, and the support block 1564 is installed on the sleeve rod 152. By pulling the pull block, the locking plate 1561 drives the fixed block 1562 to move, so that the support spring 1563 is compressed. At this time, you can turn the knob 155 to fix After the vertical rod 151 extends the length of the sleeve r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com