Pretreatment device for mold machining

A mold processing and pretreatment technology, which is applied in lighting and heating equipment, dry cargo handling, filtering and screening, etc., can solve the problem of insufficient preheating of raw materials, achieve uniform heating, improve dispersion effect, and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

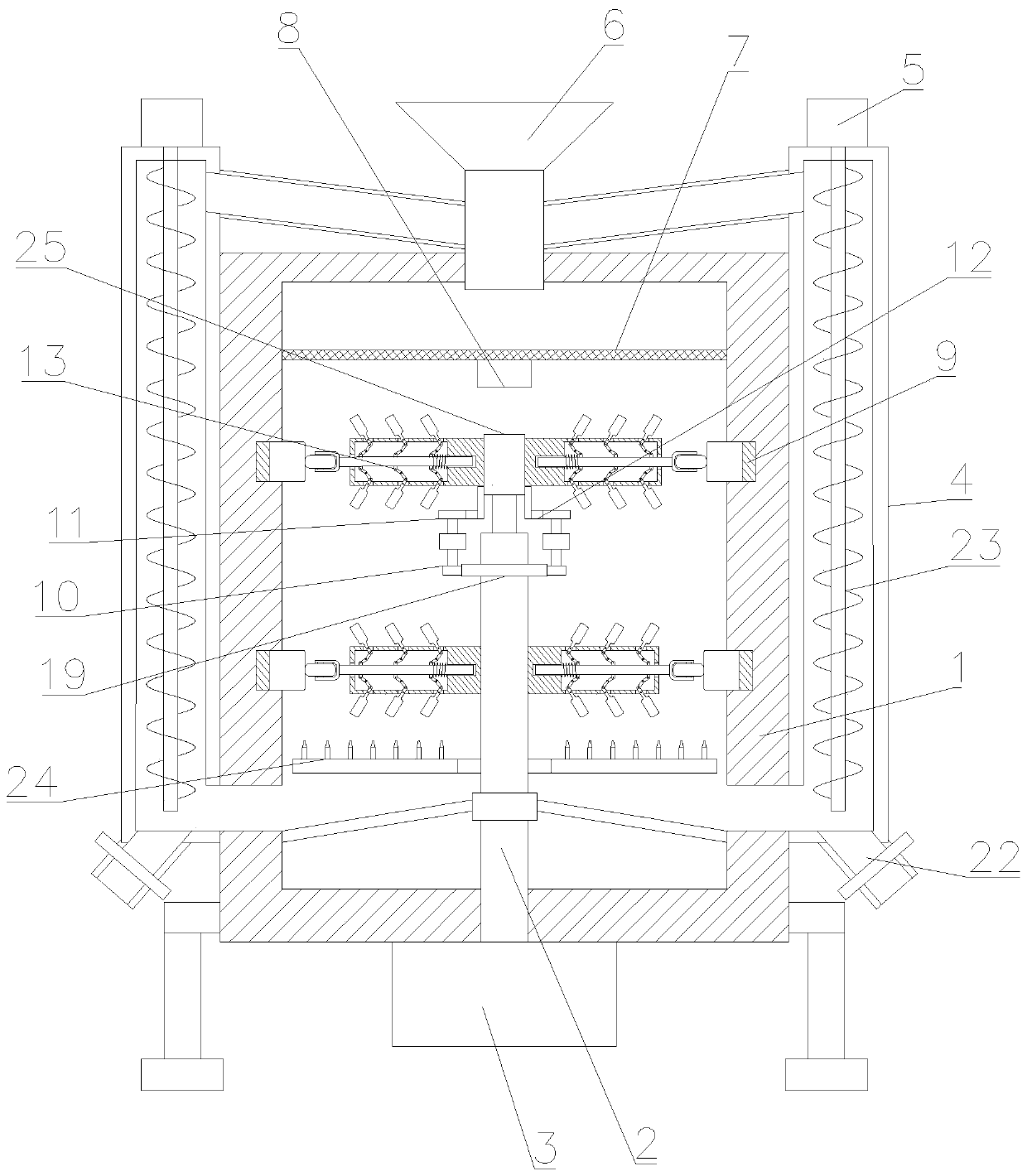

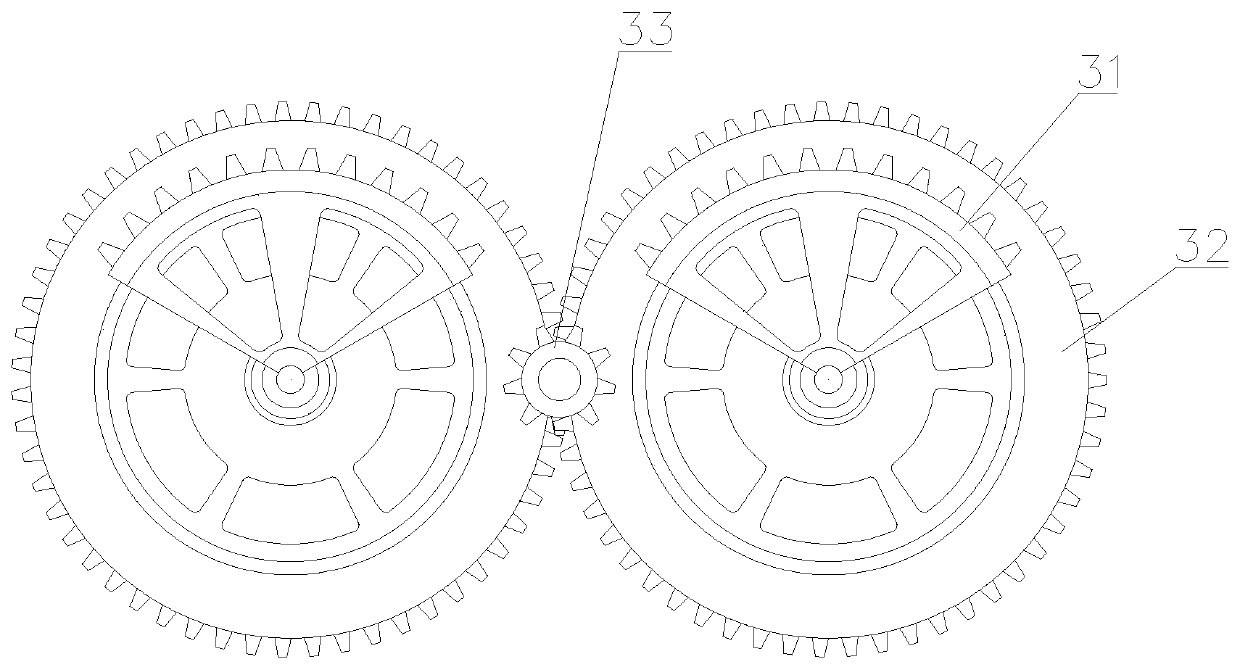

[0030] see Figure 1~4 , in Embodiment 1 of the present invention, a pretreatment device for mold processing, including a main body 1 with a cavity for dispersing and heating raw materials inside, and a distributing part, a dispersing part, and a heating part are arranged inside the main body 1 And arrange the circulation part 4 on both sides of the main body 1;

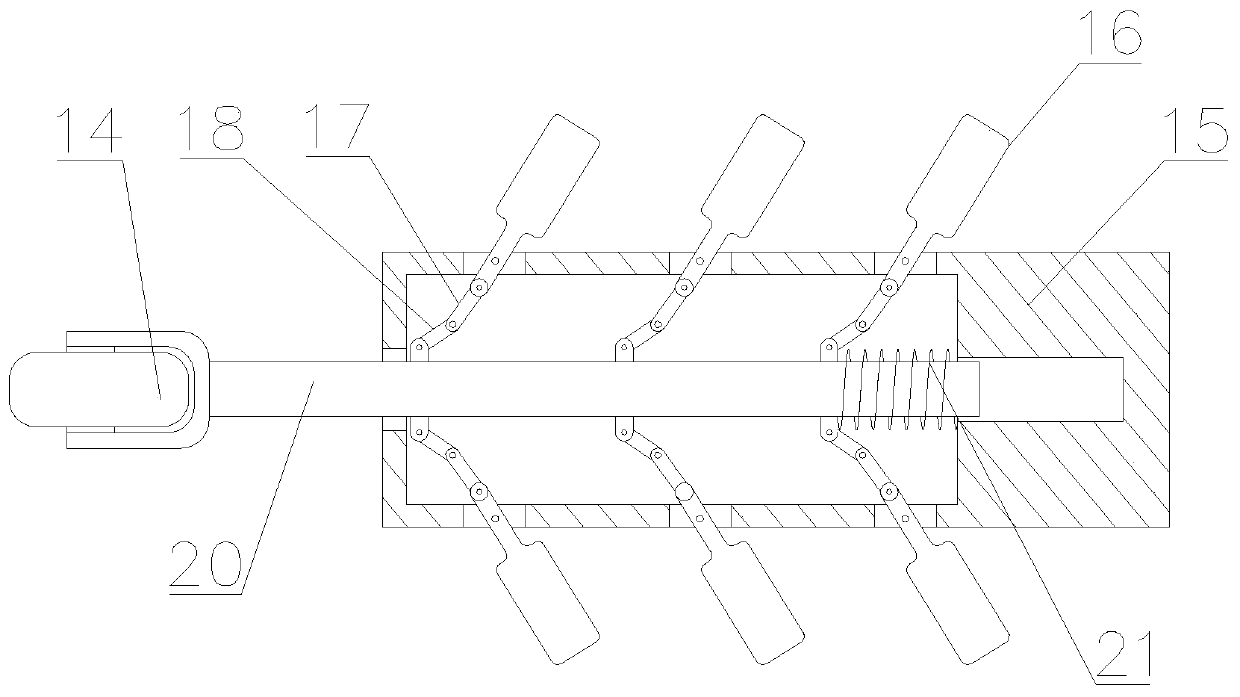

[0031] The dispersing part includes a rotating shaft 2 reciprocatingly arranged inside the main body 1. Two sets of mixing assemblies 13 rotating at a differential speed are arranged on the rotating shaft 2. Two sets of mixing assemblies 13 rotating at a differential speed are used to disperse materials at different speeds. , to improve the heating effect; the mixing assembly 13 includes a mixing piece 15 and a moving rod 20 slidingly arranged inside the mixing piece 15, and one end of the moving rod 20 protruding from the mixing piece 15 is fixedly installed with a driving ring that interferes with the inside of the...

Embodiment 2

[0033] see Figure 1~4 The main difference between the present embodiment 2 and the embodiment 1 is that the material distributing part includes a material distributing net 7 fixedly installed above the rotating shaft 2, and a vibrating motor 8 is arranged at the bottom of the distributing net 7, and the vibrating motor 8 drives the dispensing The net 7 vibrates up and down to disperse the material and improve the heating effect.

[0034] The heating component includes a gas delivery coil 24 fixed inside the main body 1 and a plurality of spray heads arranged in an array on the gas delivery coil 24, the nozzles communicate with the inside of the gas delivery coil 24, and the gas delivery The coil 24 is externally connected with heated air, and the air conveying coil 24 is arranged under the mixing assembly 13; the air conveying coil 24 is externally connected with heated air, and the falling material is heated through the nozzle.

[0035] A plurality of B connecting rods 18 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com