Replacing process of wind tower foundation ring upper flange

A technology of foundation ring and flange, which is applied in the field of flange replacement process on the wind tower foundation ring, can solve the problems of prolonging the service life of the foundation ring base, and achieve the effects of increasing revenue, reducing cost and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

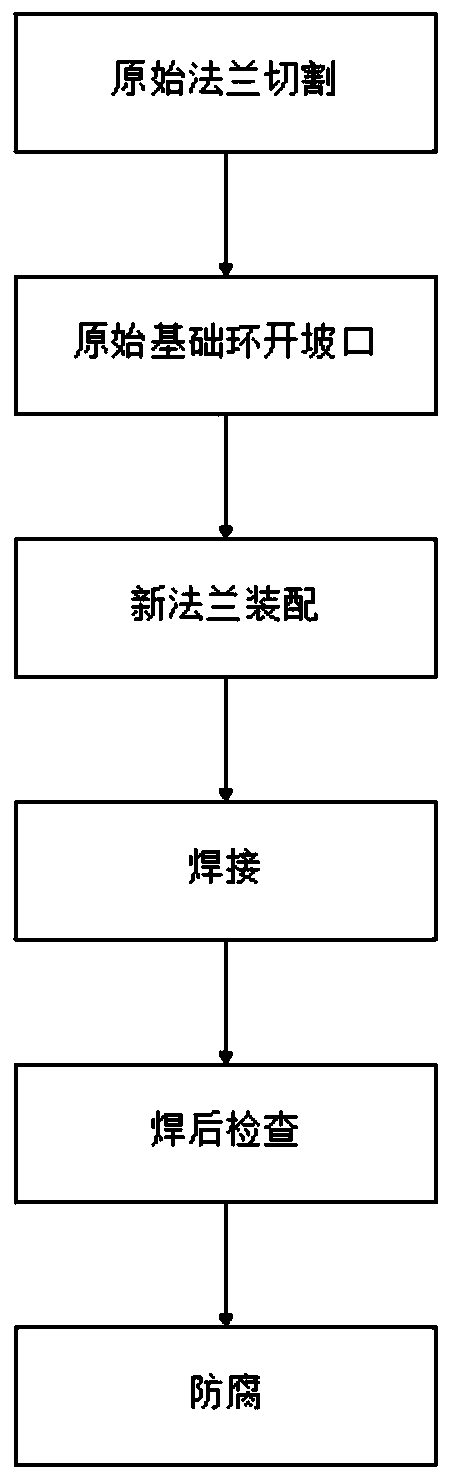

[0024] refer to figure 1 , the replacement process of the flange on the wind tower foundation ring, including the following steps:

[0025] S1: The base ring is made of Q345E grade steel, a low-temperature material;

[0026] Preparations before cutting: Cover the wires, electrical components and other things that cannot be removed in the foundation of the tower with flame-retardant plastic cloth or other items to prevent pollution or damage during the operation. And during any operation after welding, it is not allowed to damage the existing base ring cylinder and new flange anti-corrosion coating, take protective measures for the existing cylinder, bolt holes and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com