Large-scale production process for galvanic pile of MWGW-level electrolytic cell

A production process, electrolytic cell technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the lack of affordable components and automated manufacturing processes, high electrolytic cell material costs and manufacturing costs, hindering electrolytic cell stacks Large-scale production and other problems, to achieve the effect of improving production repeatability, facilitating quality supervision, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

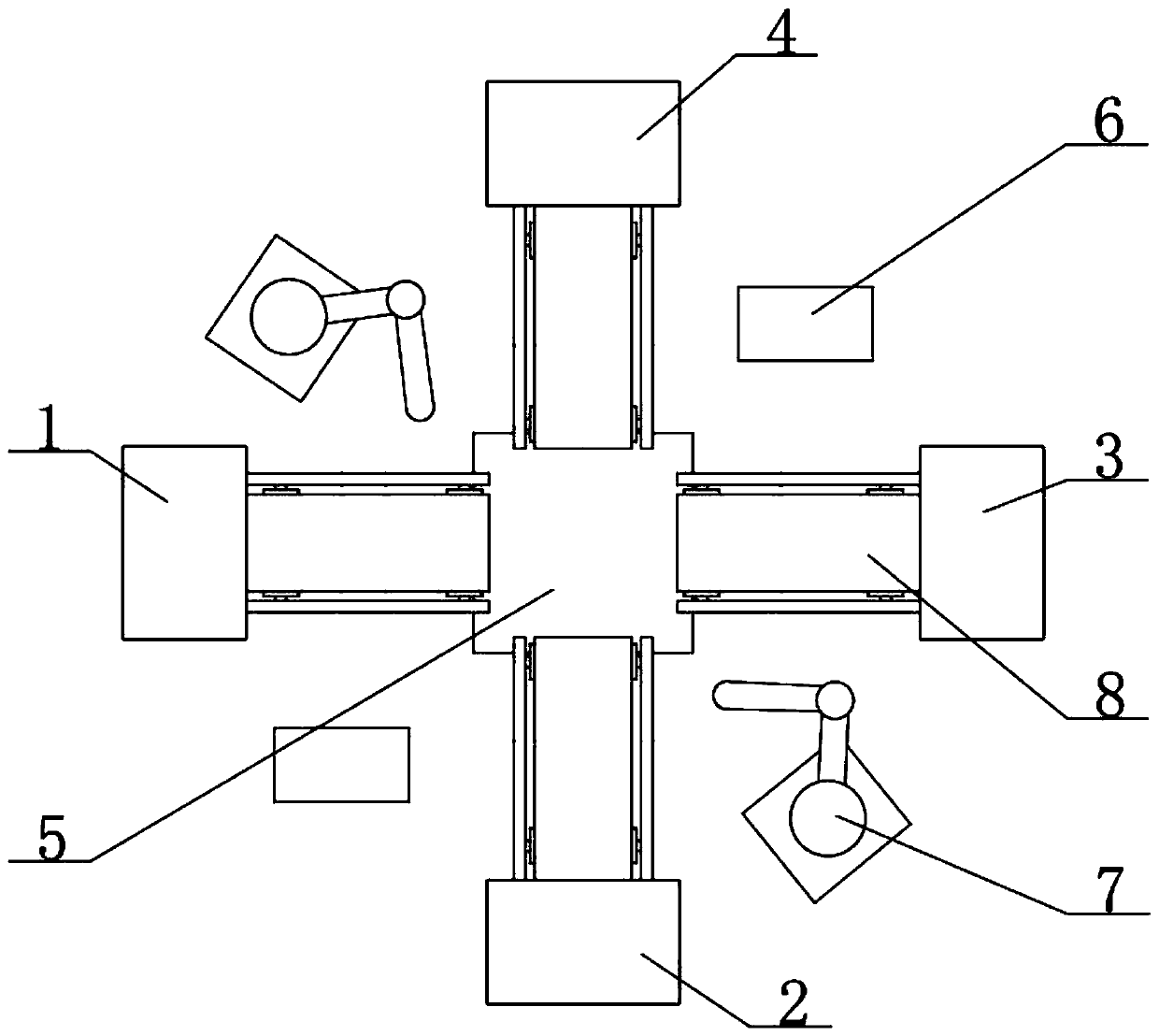

[0017] see figure 1 , the present invention provides a technical solution:

[0018] A large-scale production process of MWGW-level electrolytic cell stacks, including on-site inspection and management equipment 6, a mechanical arm 7 and a belt conveyor 8, one end of the belt conveyor is connected to an automatic gravity induction assembly platform 5, which is located on the automatic gravity induction assembly platform The belt conveyor 8 on the left side of 5 is connected with the plate feeding port 1, which is located on the lower side of the automatic gravity induction assembly platform 5. The belt conveyor 8 is connected with the sealing material feeding port 2, and is located on the right side of the automatic gravity induction assembly platform 5. The machine 8 is connected with a nickel mesh feed port 3, and the belt conveyor 8 located on the upper side of the automatic gravity induction assembly platform 5 is connected with a diaphragm feed port 4, and there are on-sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com