Novel batching hopper

A batching hopper, a new type of technology, applied in the field of new batching hoppers, can solve the problems of accelerated equipment aging, excessive size and particle size, affecting product quality, etc., and achieve the effect of prolonging service life, ensuring batching ratio, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

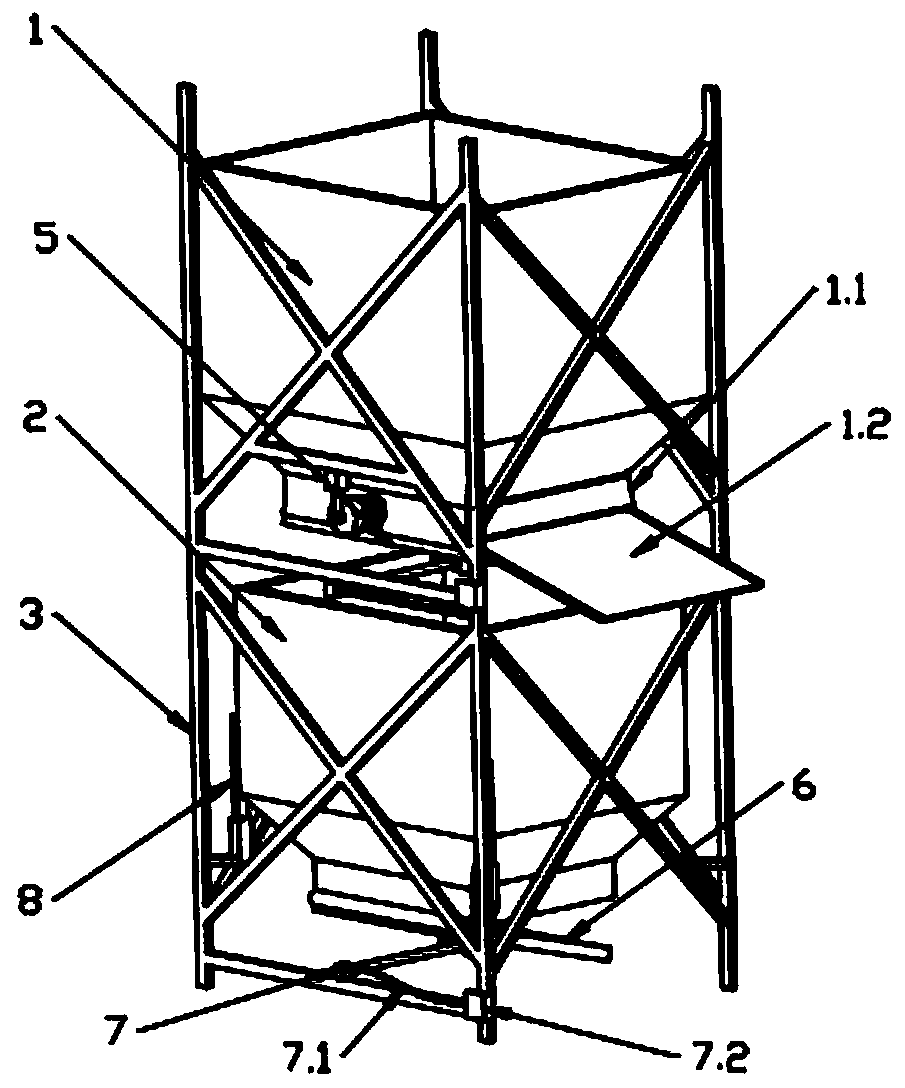

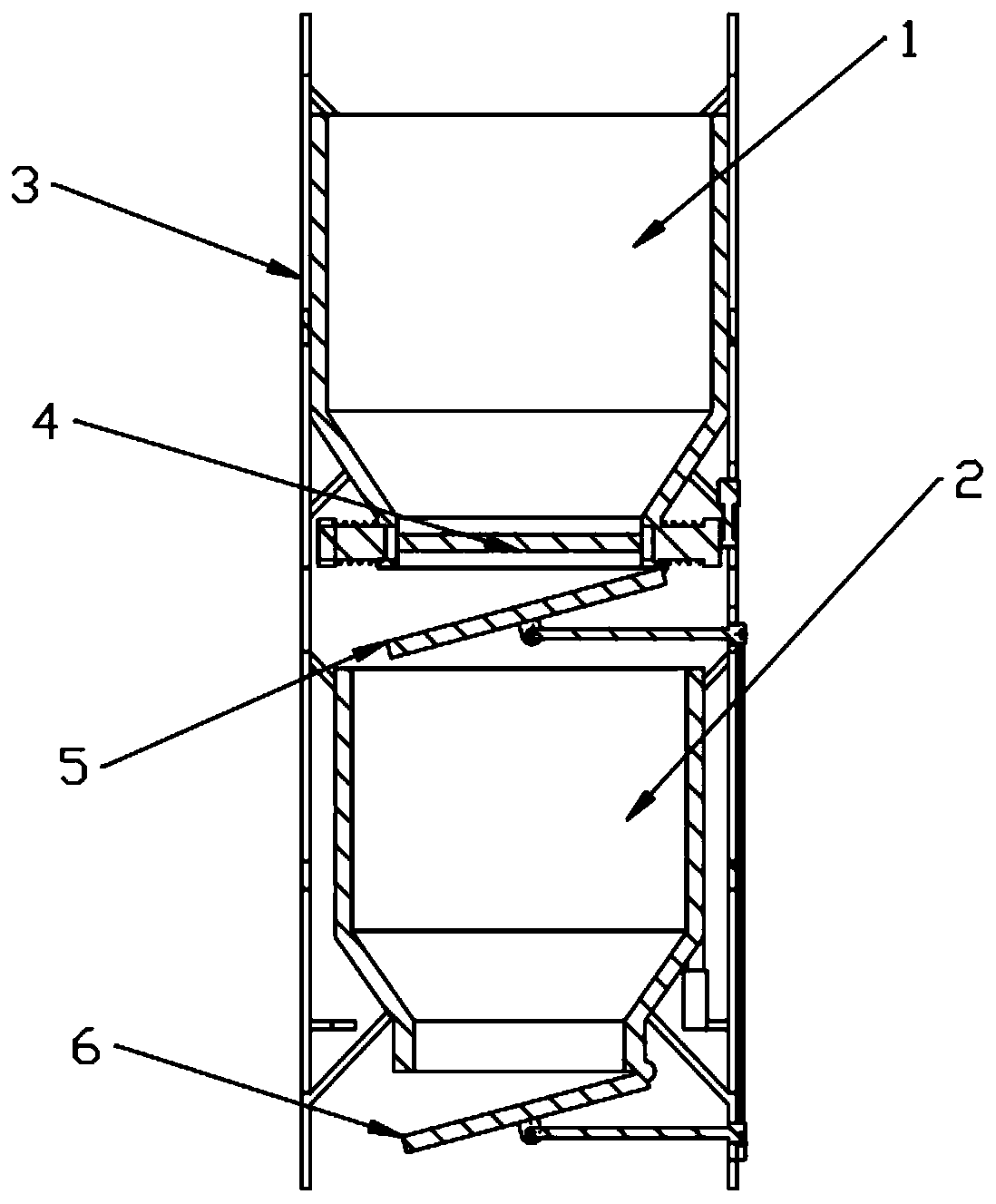

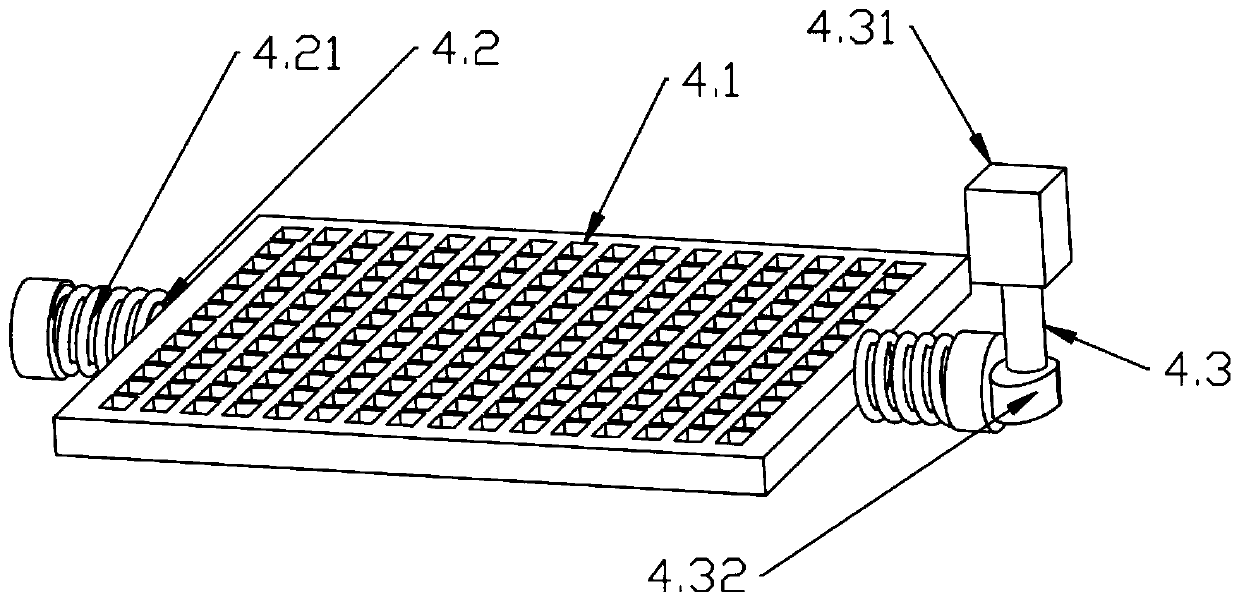

[0018] combined with Figure 1~5 , a new type of batching hopper, including a temporary storage hopper 1 and a metering hopper 2, the outside of the temporary storage hopper 1 is provided with a support frame 3 fixedly connected to it, and the internal discharge port of the temporary storage hopper 1 is provided with a matching A vibrating grate 4, a discharge door 5 hingedly connected to the outlet of the temporary storage hopper 1 is arranged below the discharge port, the metering hopper 2 is arranged below the temporary storage hopper 1, and its outside is uniformly provided with a The support column 8, the middle part of the support column 8 is provided with a weighing device 8.3, the support column 8 is vertically arranged, and its end away from the metering bucket is fixedly connected with the support frame 3, and the outlet of the metering bucket 2 A discharge door 2 6 hingedly connected to it is arranged below, and a control panel 9 and a power supply 10 fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com