Composite leaf spring and manufacturing method thereof

A technology for composite material boards and manufacturing methods, which is applied in the cutting of textile materials, fabrics, textiles, etc., can solve problems such as layered damage of composite material leaf springs, and achieve the effects of increasing strength, improving shear resistance, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

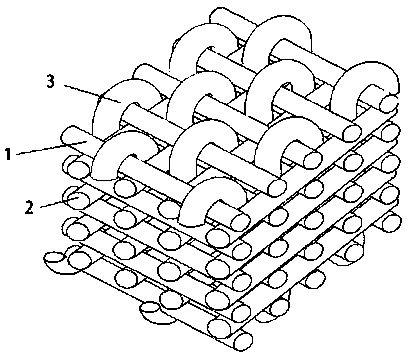

[0022] see Figure 1~6 , in an embodiment of the present invention, a composite material leaf spring structure, the composite material leaf spring 10 is composed of warp yarn 1, weft yarn 2 and weft yarn 3, and the specific form of the warp yarn 1, weft yarn 2 and weft yarn 3 Without limitation, in this embodiment, preferably, the warp yarn 1 and the weft yarn 2 are 660tex E-glass fibers, and the vertical yarns 3 are 400tex E-glass fibers.

[0023] The preparation method of the composite leaf spring structure, the steps are as follows:

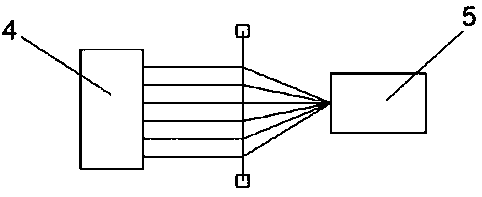

[0024] 1) Put the bobbin on the creel 4, the vertical yarn 3 passes through the eyelet of the heald, the warp and weft yarn 2 directly passes through the yarn drawing hole through the gap, and then weaves it on the three-dimensional rapier loom 5, and uses the yarn dividing rod to separate the The warp yarn 1 is separated to form a shed for the weft yarn 2 to pass through. The vertical yarn 3 is located at the uppermost and lowermost ends res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com