Quantitative filling machine for powder medicine

A quantitative tank and medicine technology, applied in packaging, transportation and packaging, packaging item types, etc., can solve the problems of high pricing and high maintenance costs, and achieve the effects of reducing operation difficulty, improving production efficiency, and improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

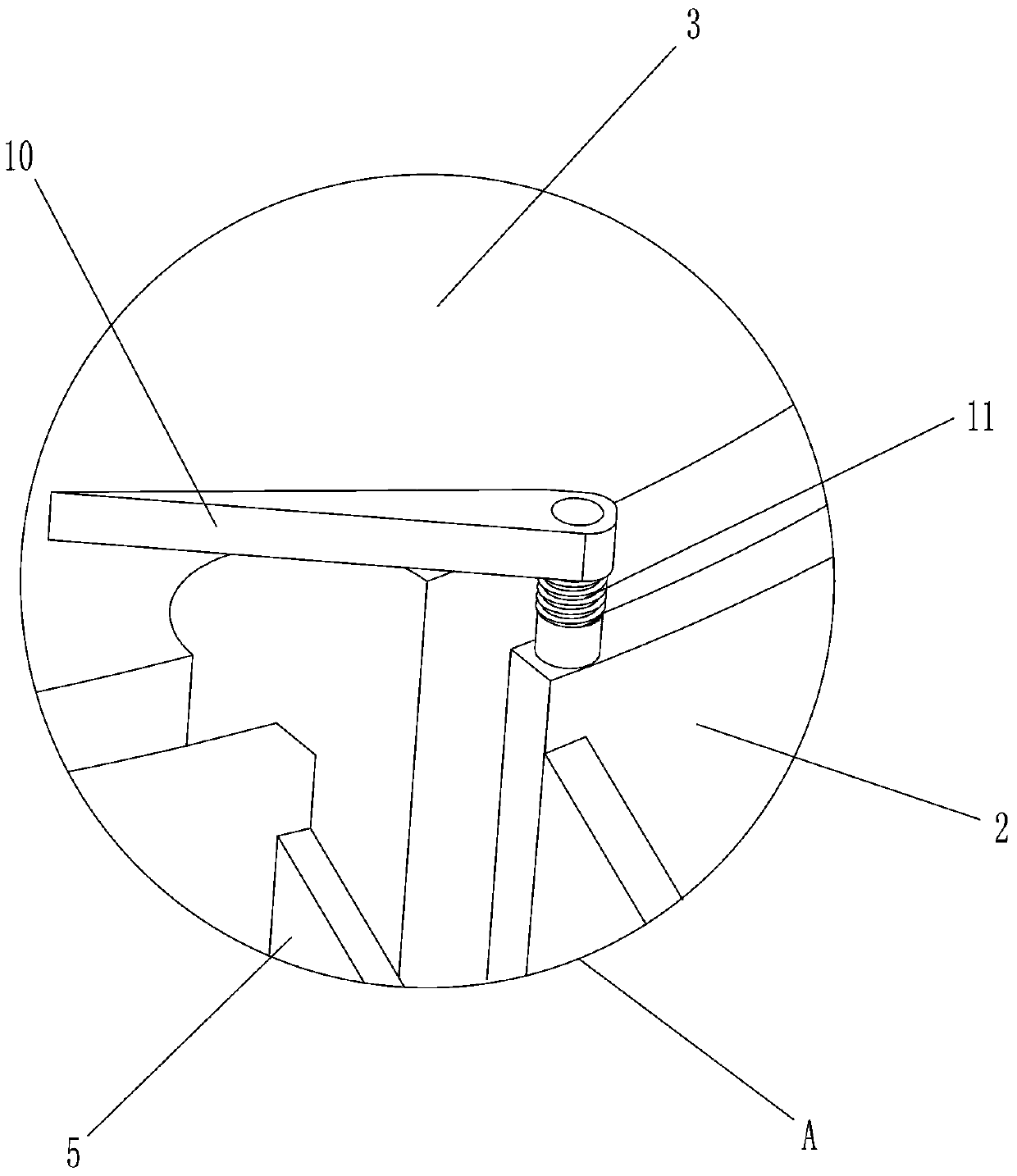

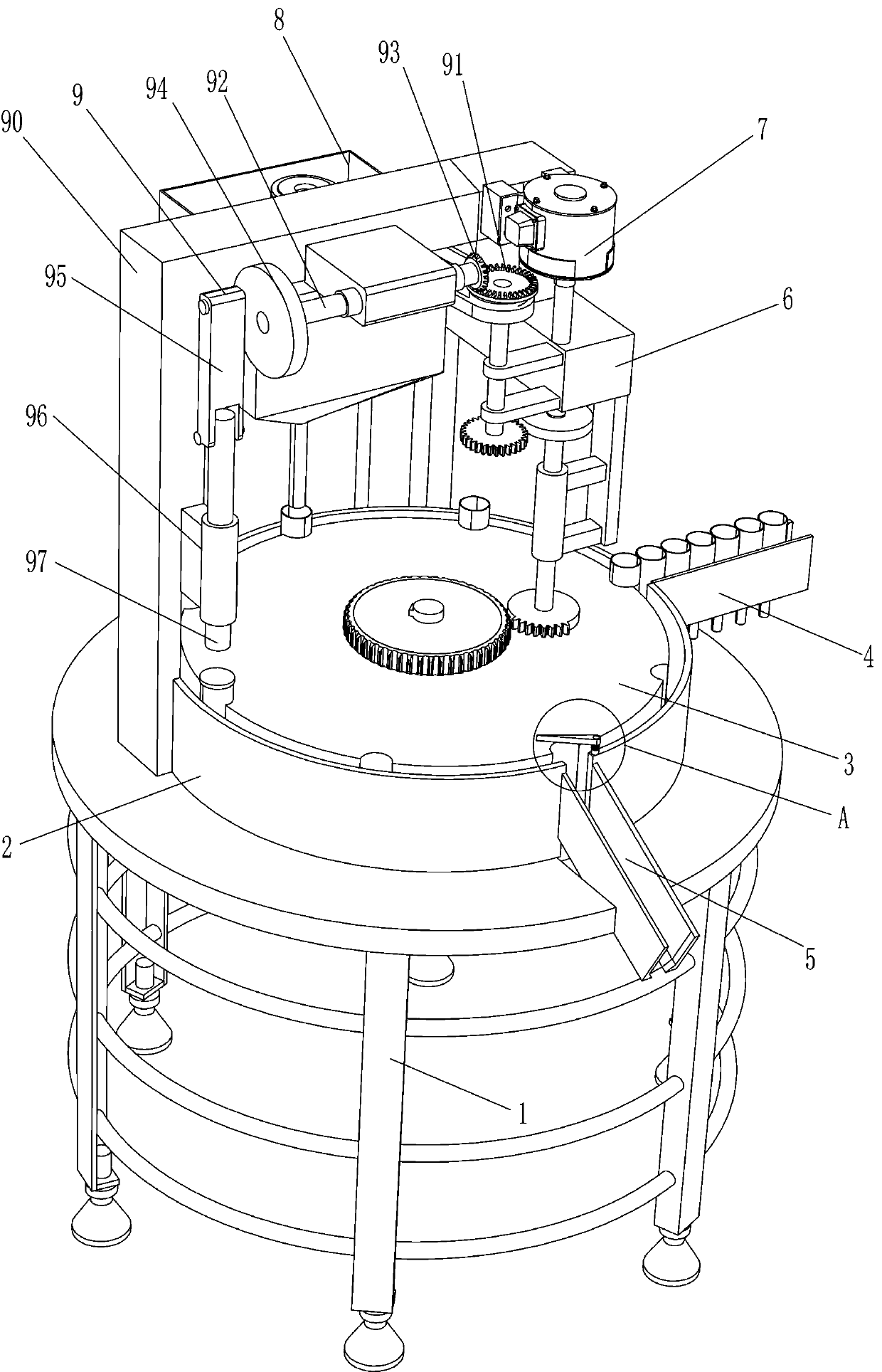

[0024] A quantitative canning machine for powder medicine, such as Figure 1-2 As shown, it includes a frame 1, an annular plate 2, a turntable 3, a feed hopper 4, a discharge hopper 5, a support 6, a rotary feeding mechanism 7 and a feeding mechanism 8, and the top of the frame 1 is provided with an annular plate 2, an annular plate 2 The inner rotation type is provided with a turntable 3, and eight slots are evenly spaced around the turntable 3, the right side of the ring plate 2 is connected with the feed hopper 4, the front side of the ring plate 2 is connected with the discharge hopper 5, and the rear of the top of the frame 1 A support 6 is installed on the side, a rotary feeding mechanism 7 is installed on the front side of the top of the bracket 6, a feeding mechanism 8 is installed on the top rear side of the bracket 6, the rotary feeding mechanism 7 is connected with the feeding mechanism 8, and the rotary feeding mechanism 7 is used to drive the turntable 3 Intermit...

Embodiment 2

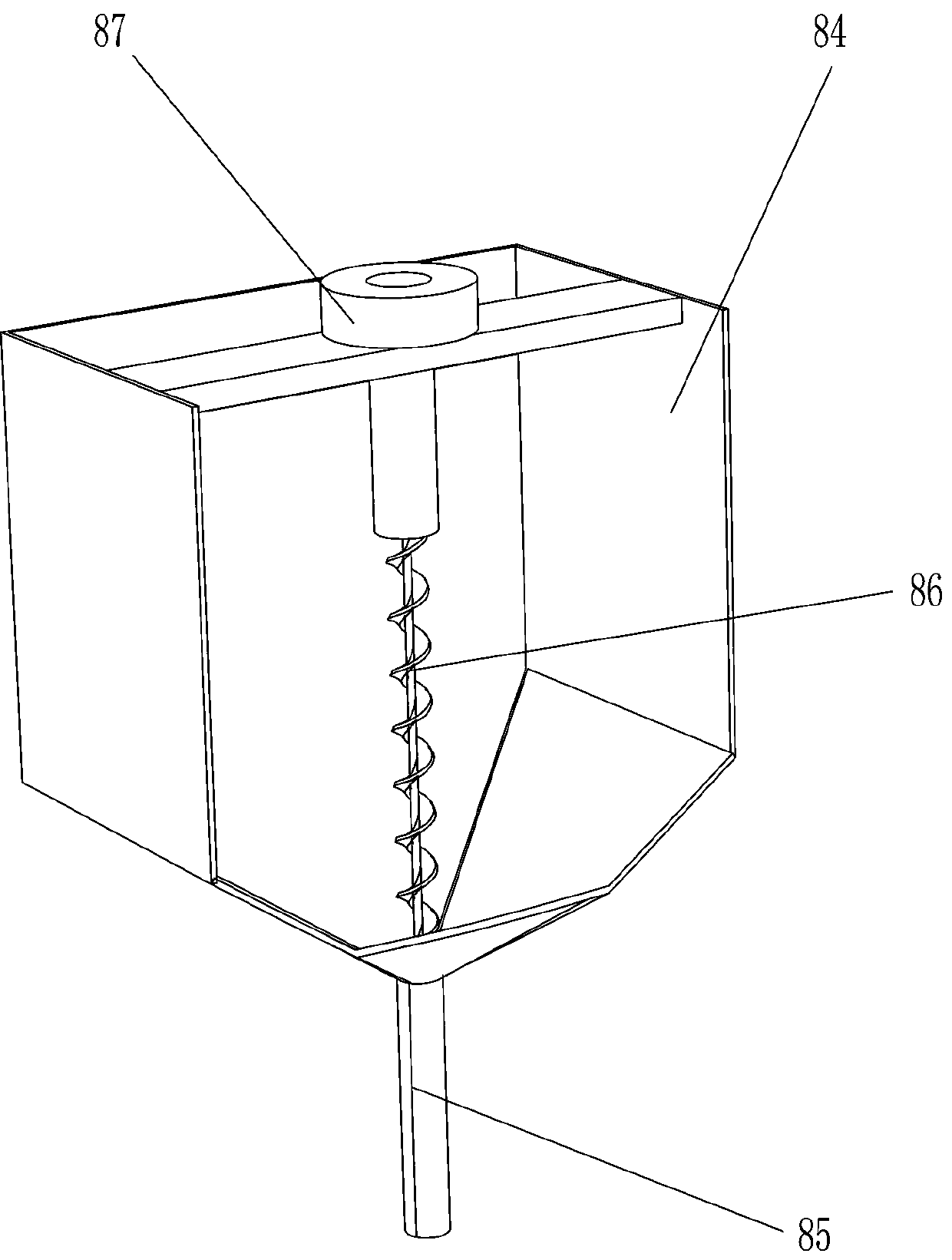

[0029] On the basis of Example 1, such as Figure 3-4 As shown, the capping mechanism 9 is also included, and the capping mechanism 9 includes a mounting frame 90, a large bevel gear 91, a connecting shaft 92, a small bevel gear 93, a disc 94, a connecting rod 95, a guide sleeve 96 and an extruding rod 97, a mounting frame 90 is installed on the top of the frame 1, the mounting frame 90 is connected with the left side of the support 6 top, a large bevel gear 91 is installed on the top of the belt pulley 87 at the top of the rotating rod 81, and the front side of the mounting frame 90 is rotatably equipped with a connecting shaft 92, the right end of the connecting shaft 92 is connected with a small bevel gear 93, the small bevel gear 93 meshes with the large bevel gear 91, the left end of the connecting shaft 92 is rotatably connected with a disk 94, and the lower part of the front side of the mounting bracket 90 is fixedly connected with a guide sleeve 96, An extruding rod 97...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com