Colorful double-layer bottom blank soft light polished crystal marble and preparation method thereof

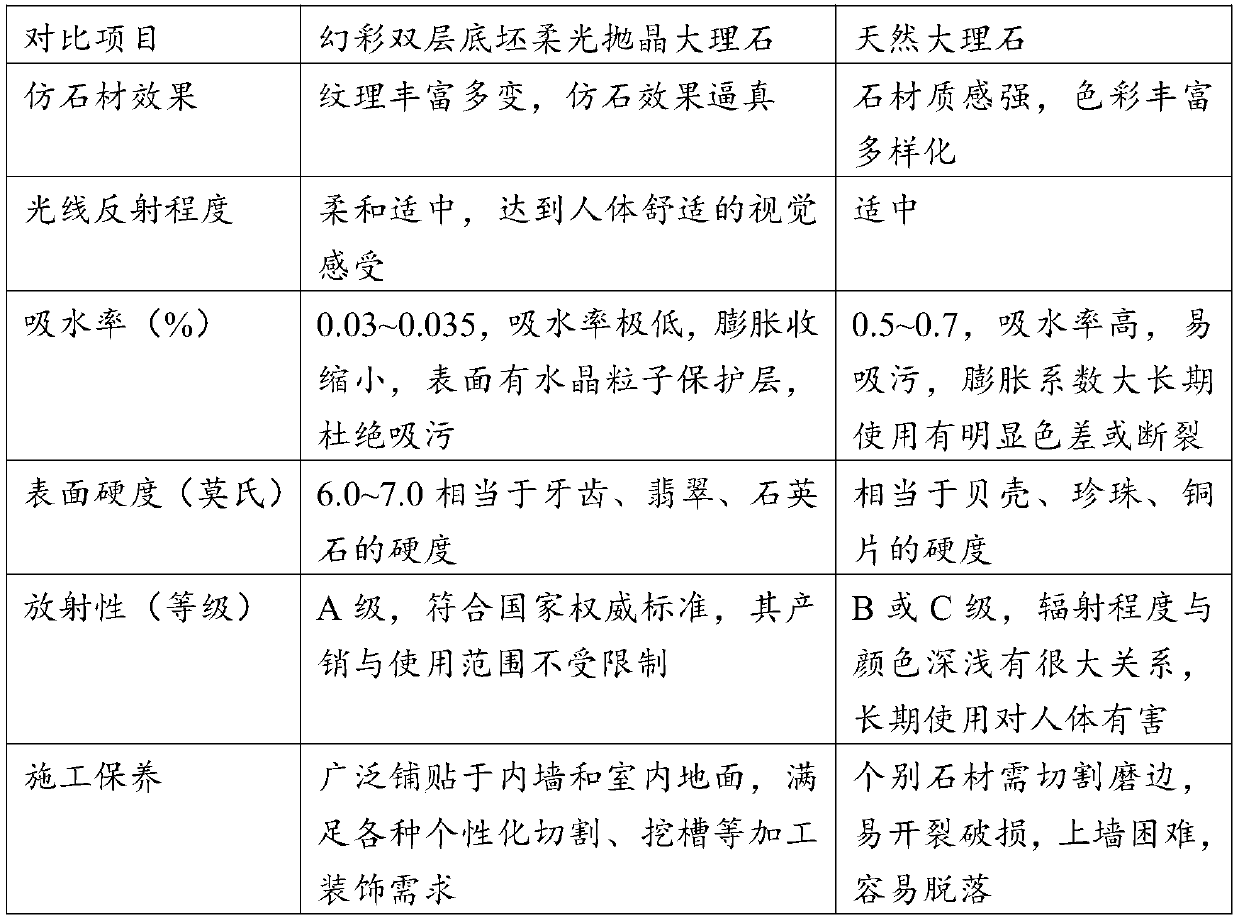

A double bottom, marble technology, applied in clay products, other household appliances, applications, etc., can solve the problems of monotonous layers, seepage and discoloration of surface glaze, lack of three-dimensional stone sense, etc., to improve the environment, realistic transparency, and strong three-dimensional sense. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

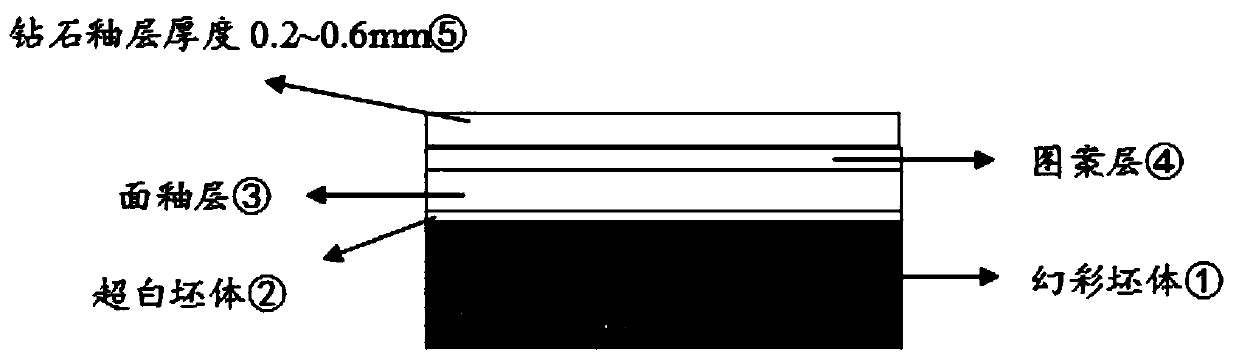

[0024] The invention provides a method for preparing soft-polished crystal marble with a double-layer bottom base of magic color, which comprises the following steps:

[0025] (1) prepare the phantom green body;

[0026] (2) Super white green body is set on the phantom color green body;

[0027] (3) top glaze is set on the ultra-white body to obtain a top glaze layer;

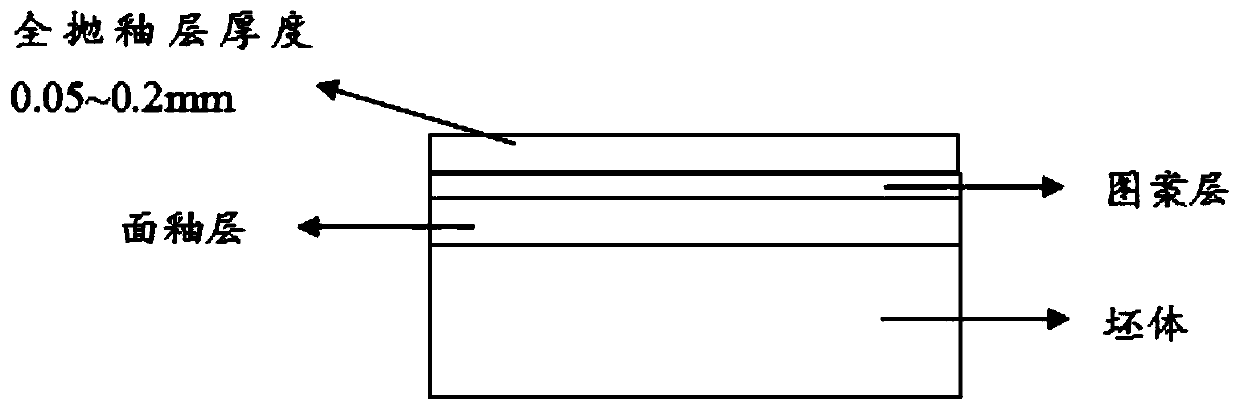

[0028] (4) print the marble pattern on the glaze layer to obtain the pattern layer;

[0029] (5) negative ion diamond glaze is arranged on pattern layer above, obtains diamond glaze layer; Described negative ion diamond glaze comprises diamond glaze and negative ion powder;

[0030] (6) Fire and polish the product obtained in step (5) to obtain the soft-polished crystal-polished marble with a double-layer bottom base.

[0031] In the present invention, the magic body in the step (1) preferably includes the following components by weight: 8.0-12.0 parts of high-temperature sand, 2.0-4.0 parts of water abrasiv...

Embodiment 1

[0080] (1) Preparation of phantom body: take 10.0 parts of high-temperature sand, 3.0 parts of water abrasive, 28.0 parts of water scrub, 7.0 parts of low-temperature sand, 25.0 parts of quartz sand, 19.0 parts of kaolin, 2.0 parts of burnt talc, 1.2 parts of bentonite, black mud 2.0 parts, 2.0 parts of color material, the above-mentioned raw materials are subjected to powder milling, molding and drying processes in turn to obtain a phantom green body;

[0081] (2) Set the ultra-white body on the magic body: 3.0 parts of water-taking abrasive, 20.5 parts of kaolin, 38.0 parts of water scrub, 3.0 parts of ultra-white ball clay, 2.5 parts of burnt talc, 15.0 parts of quartz sand, 9.0 parts of high-temperature sand, 1.2 parts of bentonite and 2.5 parts of black mud. The above-mentioned raw materials are sequentially subjected to powder making, molding, and drying processes to obtain an ultra-white body; The thickness ratio to the ultra-white green body is 6:1;

[0082] (3) Set t...

Embodiment 2

[0087] (1) Preparation of phantom body: take 8.0 parts of high-temperature sand, 2.0 parts of water abrasive, 25.0 parts of water scrub, 6.0 parts of low-temperature sand, 23.0 parts of quartz sand, 18.0 parts of kaolin, 1.5 parts of burnt talc, 1.0 parts of bentonite, black mud 1.0 part, 1.0 part of color material, the above-mentioned raw materials are subjected to powder milling, molding and drying processes in sequence to obtain a phantom green body;

[0088] (2) Set the ultra-white body on the magic body: 2.5 parts of water-taking abrasive, 18.5 parts of kaolin, 36.0 parts of water scrub, 2.5 parts of ultra-white ball clay, 2.0 parts of burnt talc, 13.5 parts of quartz sand, 8.5 parts of high-temperature sand, 1.0 parts of bentonite and 2.0 parts of black mud, the above-mentioned raw materials are sequentially subjected to powder making, molding, and drying processes to obtain an ultra-white body; the ultra-white body is placed on the magic body, and pressed by a press, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com