Liquid crystal elastomer film as well as preparation method, driving method and application thereof

A technology of liquid crystal elastomers and liquid crystal monomers, applied in liquid crystal materials, chemical instruments and methods, nonlinear optics, etc., can solve problems such as operation troubles, pattern restrictions, and smallest pixel restrictions, and achieve strong flexibility and precision High precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of liquid crystal elastomer film, its preparation method comprises the following steps:

[0033] S1. Dissolving the azo-based photo-alignment material SD1 with N,N-dimethylformamide, and then spin-coating it on a glass substrate to form an alignment coating;

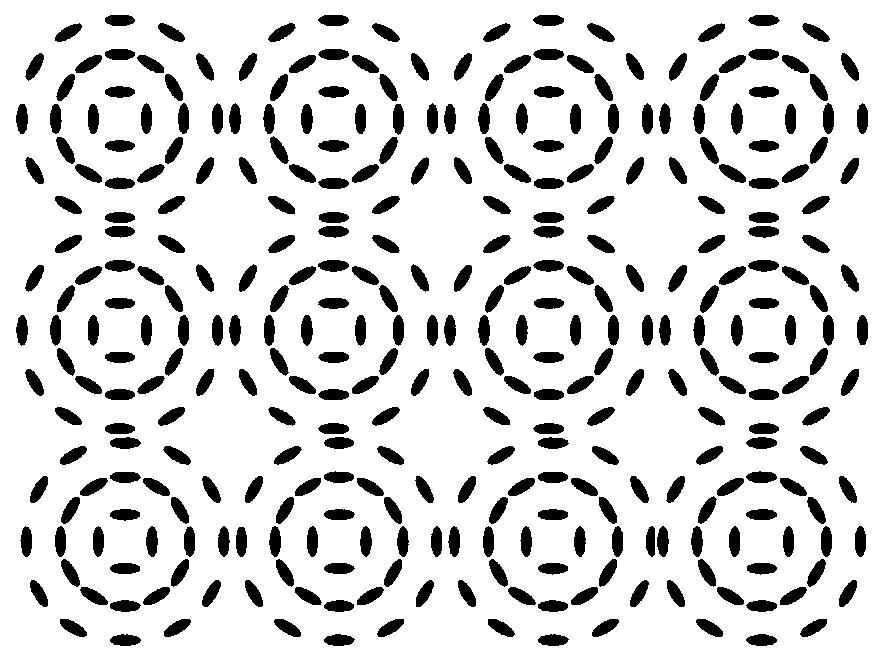

[0034] S2. Prepare a liquid crystal box by using a glass substrate with an orientation coating; then design a digital mask, the specific structure is as follows figure 1 As shown, the circular liquid crystal directors are arranged, and the alignment coating inside the liquid crystal cell is aligned using a digital mask lithography system;

[0035] S3. Take 24 parts of liquid crystal monomer A, 72 parts of liquid crystal monomer B, 3 parts of azobenzene, and 1 part of photoinitiator, mix and prepare a liquid crystal mixture, and then fill the liquid crystal mixture into a liquid crystal box; wherein, liquid crystal monomer A Specifically, 1,4-bis-[4-(6-acryloyloxyhexyloxy)-benzoyloxy]-2-methylbenzene is use...

Embodiment 2

[0038] A kind of liquid crystal elastomer film, its preparation method comprises the following steps:

[0039] S1. Dissolving the azo-based photo-alignment material PAAD-22 with N,N-dimethylformamide, and then spin-coating it on a glass substrate to form an alignment coating;

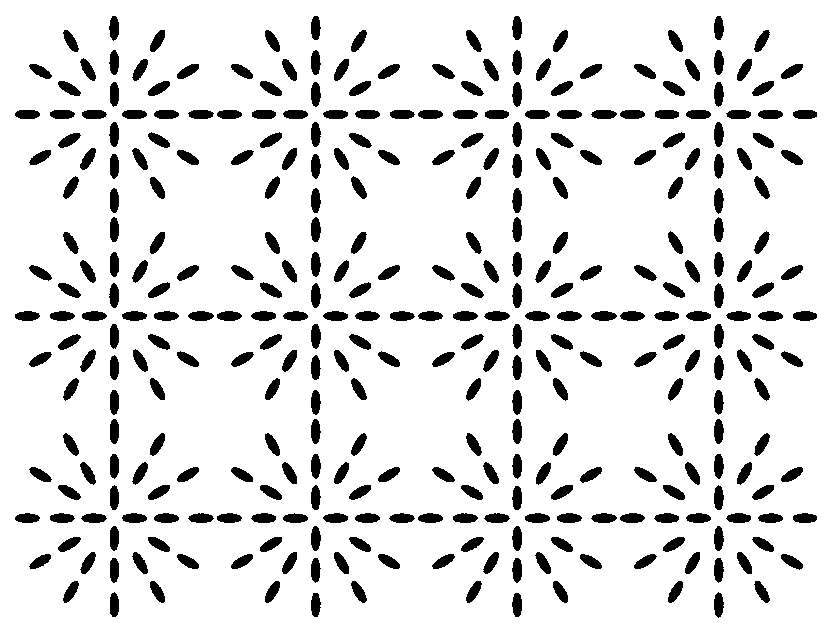

[0040] S2. Design a digital mask, the specific structure is as follows figure 2As shown, the liquid crystal directors are arranged radially, and the alignment coating on the glass substrate is oriented using a digital mask lithography system to obtain a photo-alignment layer; then a liquid crystal is prepared by using a glass substrate with a photo-alignment layer Box;

[0041] S3. Take 15 parts of liquid crystal monomer A, 80 parts of liquid crystal oligomer, 3 parts of azobenzene, and 2 parts of photoinitiator, mix and prepare a liquid crystal mixture, and then fill the liquid crystal mixture into a liquid crystal box; wherein, liquid crystal monomer A Specifically, 1,4-bis-[4-(6-acryloyloxyhexylox...

Embodiment 3

[0044] A kind of liquid crystal elastomer film, its preparation method comprises the following steps:

[0045] S1, dissolving the azo-based photo-alignment material SD1 with N-methylpyrrolidone, and then spin-coating it on a glass substrate to form an alignment coating;

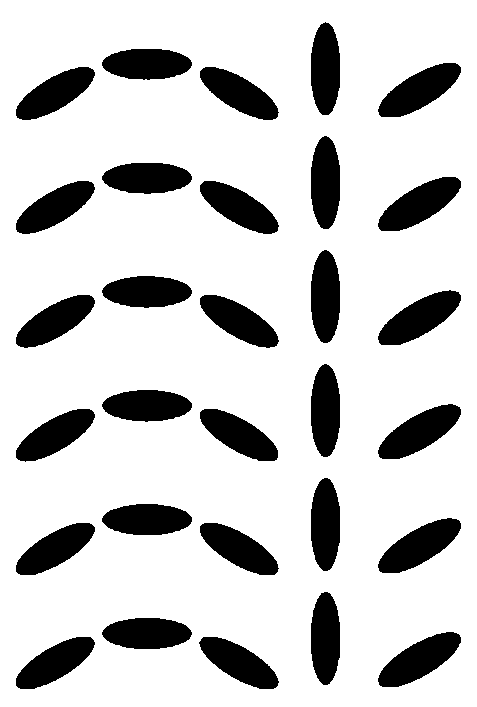

[0046] S2. Prepare a liquid crystal box by using a glass substrate with an orientation coating; then design a digital mask, the specific structure is as follows image 3 As shown, the liquid crystal director arrangement in the curved and exhibited areas, and the alignment coating inside the liquid crystal cell is aligned using a digital mask lithography system;

[0047] S3. Take 21 parts of liquid crystal monomer A, 63 parts of liquid crystal monomer B, 11 parts of liquid crystal oligomer, 3 parts of azobenzene, and 2 parts of photoinitiator, mix and prepare a liquid crystal mixture, and then fill the liquid crystal mixture into a liquid crystal box Among them, liquid crystal monomer A specifically adopts 1,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap