Corrosion protected mold compound

A technology of molding compounds and polymers, which is applied in the direction of circuits, electrical solid devices, semiconductor devices, etc., can solve the problems of reliability, stickiness of tackifiers and molding tools, etc., so as to increase reliability, prevent peeling or Separates, simplifies the effect of molding compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

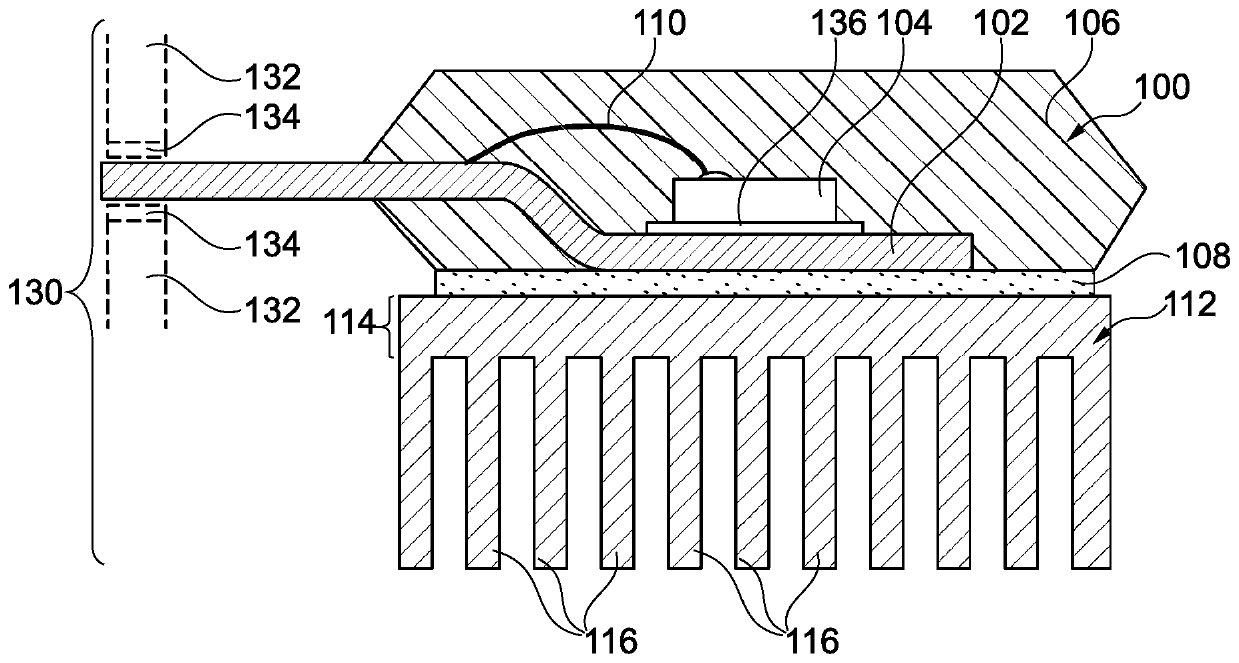

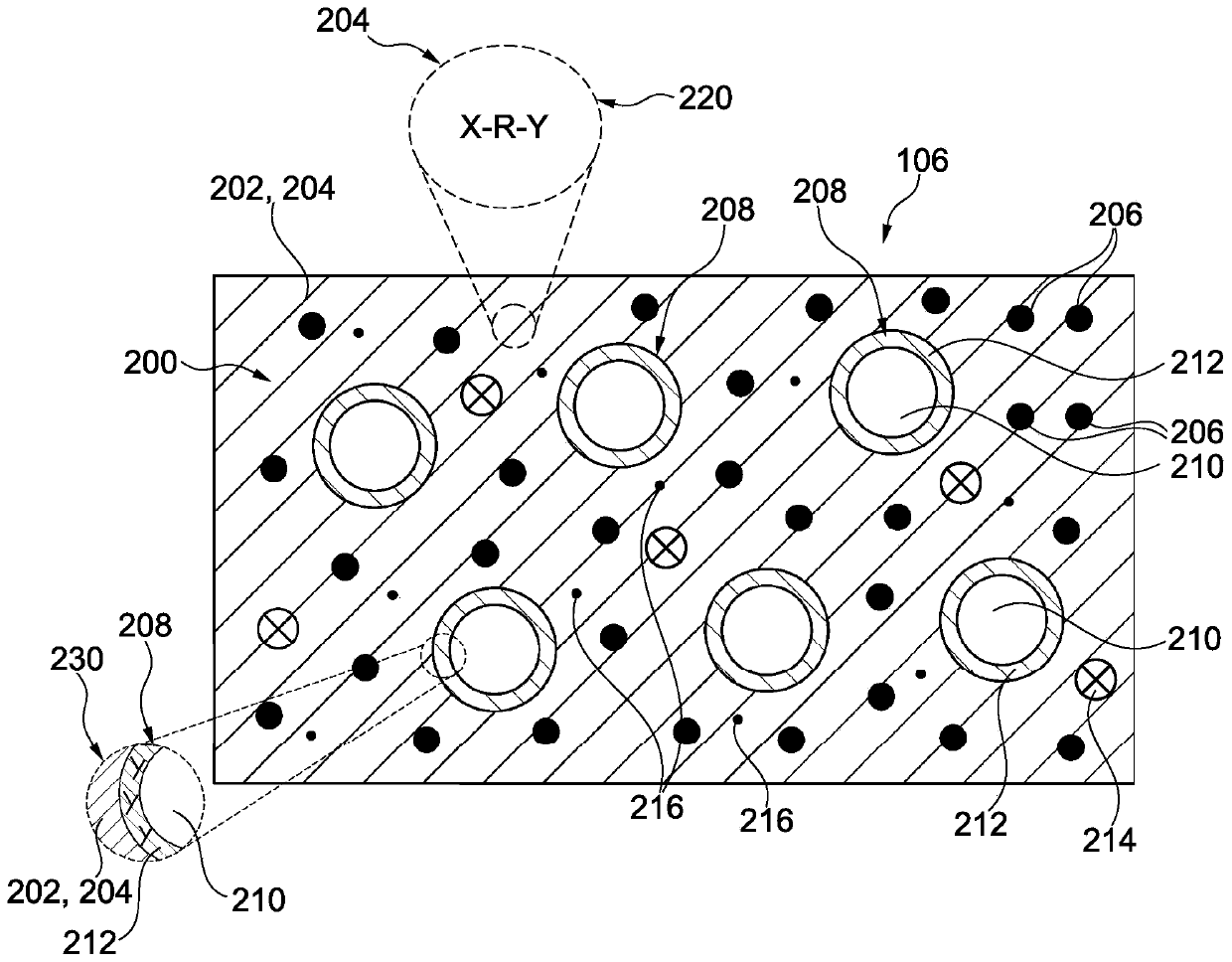

[0063] The illustrations in the figures are schematic and not to scale.

[0064] Before describing the exemplary embodiments in more detail with reference to the accompanying drawings, some general considerations will be summarized upon which the exemplary embodiments will be developed.

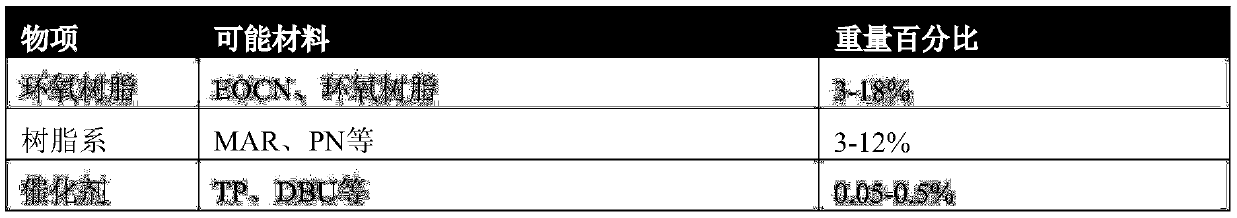

[0065] Advantageous components of molding compounds according to exemplary embodiments are disclosed in Table 1 below:

[0066]

[0067]

[0068] Table 1: Components of the molding compound according to an exemplary embodiment (all weight percentages in Table 1 are based on the total weight of the molding compound)

[0069] The implementation of the above material systems as molding compounds is easily carried out by adjusting the mixture according to the requirements of a particular application.

[0070] According to an exemplary embodiment, a molding compound is provided that includes a polymer resin, a curing agent, a filler, a catalyst, and a free tackifier. The free adhesion prom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com