A kind of water-based high-temperature medium-coating paint and preparation method thereof

A high-temperature, painting technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as complex processes, save energy, shorten process time, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This example provides a water-based high-temperature mid-coating paint, comprising the following preparation raw materials in parts by weight:

[0048] Waterborne polyurethane A: 15-20 parts, water-based polyurethane B: 15-20 parts, blocked isocyanate: 5-10 parts, amino resin: 5-10 parts, titanium dioxide: 15-20 parts, nano-precipitated barium sulfate: 10-15 parts parts, kaolin: 10-15 parts, filler: 3-7 parts, cosolvent: 3-5 parts, dispersant: 2-4 parts, substrate wetting agent: 0.5-1.0 parts, interface control agent: 1.0-3.0 parts parts, auxiliary: 1.0 to 3.0 parts.

[0049] The pigment-to-base ratio of the water-based high-temperature paint is 2-2.5:1.

[0050] Among them, the number average molecular weight of the water-based polyurethane A is 4000-6000, and the hydroxyl value is 4.2. The number average molecular weight of the water-based polyurethane B is 3000-5000, and the hydroxyl value is 2.

[0051] The solid content of blocked isocyanate is 75-85%.

[0052]...

Embodiment 2

[0059] This example provides the preparation method of water-based high-temperature medium-coating paint, including the following steps:

[0060] S1: put water-based polyurethane A, water-based polyurethane B, blocked isocyanate and amino resin in sequence, stir at a speed of 100-200 rpm, add the remaining preparation raw materials while stirring, increase the rotation speed to 200-300 rpm and stir for 15-20 min;

[0061] S2: Increase the stirring speed to 300-400 rpm, and grind after stirring for 30-45 min.

Embodiment 3

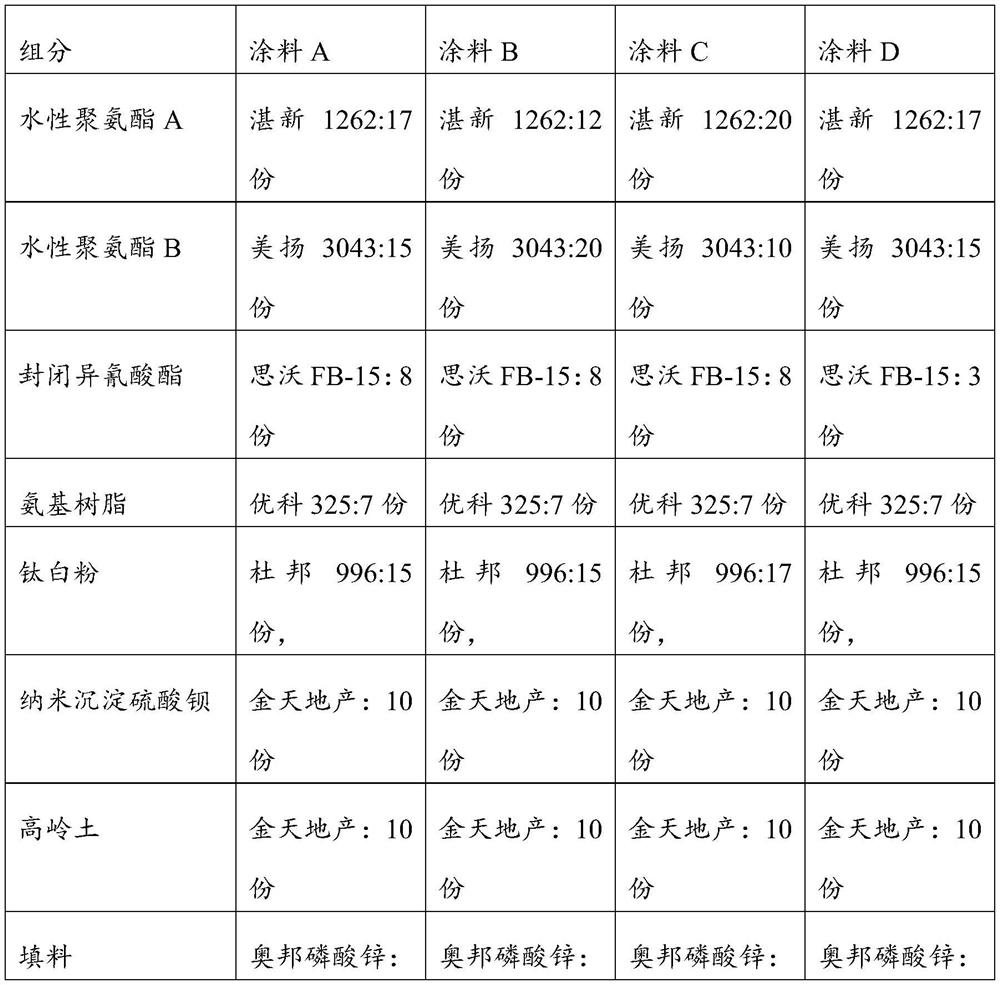

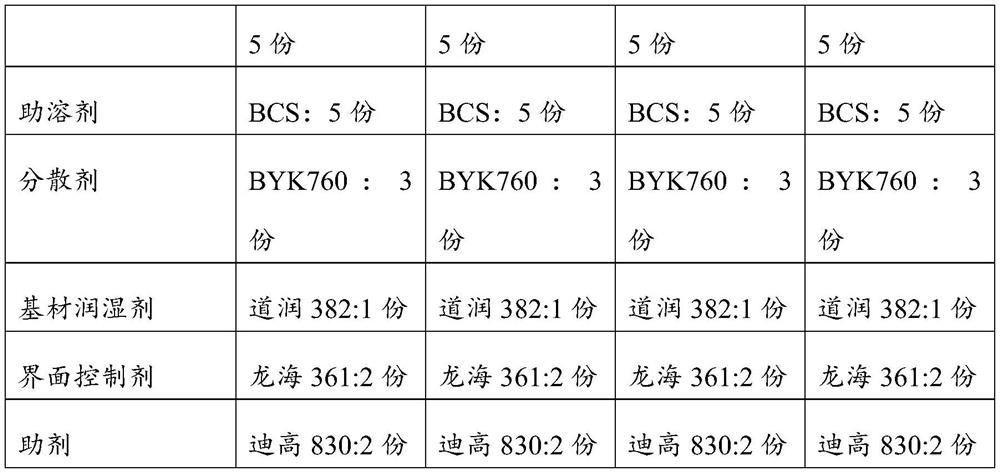

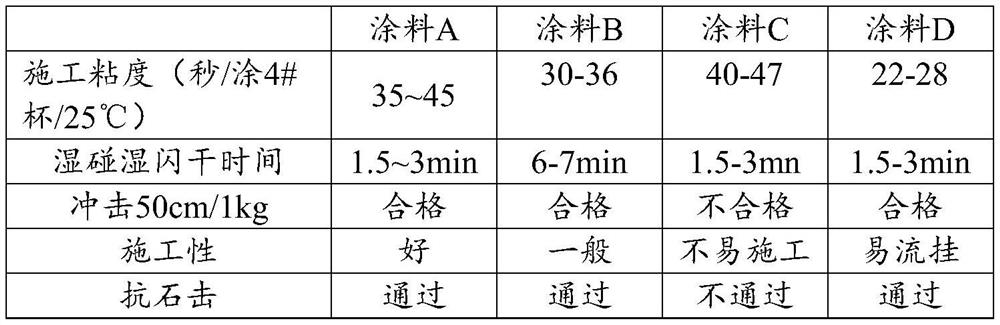

[0063] In this example, according to the preparation raw material ratio provided in Example 1 and the preparation method provided in Example 2, 5 kinds of coatings were prepared under the same process conditions, and the specific proportions are shown in Table 1.

[0064]Table 1 paint ratio details

[0065]

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com