Desulfurization integrated device capable of accurately controlling injection amount of desulfurizing agent and desulfurization method

A technology of precise control and desulfurization agent, applied in sequence/logic controller program control, electrical program control, gas fuel, etc., can solve the problem of ineffective development and utilization of natural gas production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

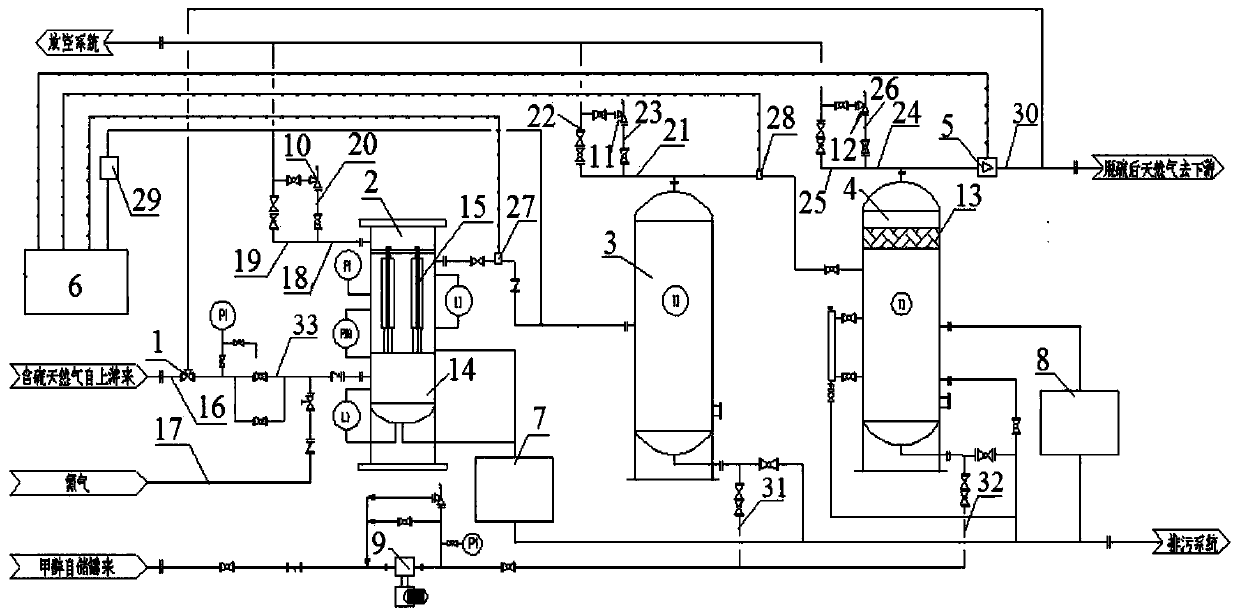

[0044] This embodiment provides an integrated desulfurization device for precisely controlling the amount of desulfurization agent injected, including a desulfurization tank 3, a PLC control system, a dosing system 6 and a gas-liquid separator 4 arranged on a skid, and the desulfurization tank 3 The gas outlet communicates with the middle part of the gas-liquid separator 4 through a pipeline;

[0045] Described dosing system 6 comprises dosing pump 29, hydrogen sulfide detector one 27, hydrogen sulfide detector two 28 and flowmeter 5, and described hydrogen sulfide detector one 27 is arranged on the natural gas inlet pipeline of desulfurization tank 3, so The hydrogen sulfide detector II 28 is arranged on the pipeline between the desulfurization tank 3 and the gas-liquid separator 4, the flowmeter 5 is arranged on the desulfurized natural gas outlet pipeline 30 of the gas-liquid separator 4, and the dosing pump 29 The pipeline communicates with the desulfurization tank 3, and ...

Embodiment 2

[0051] On the basis of Embodiment 1, this embodiment provides an integrated desulfurization device that precisely controls the injection amount of desulfurization agent. The skid is also provided with a filter separator 2, and the gas outlet of the filter separator 2 passes through The pipeline communicates with the middle of the desulfurization tank 3 .

[0052] The filter separator 2 is used to filter out solid impurities such as sediment in the natural gas, and then enter the desulfurization tank 3 from the bottom of the filter separator 2 to remove hydrogen sulfide in the sulfur-containing natural gas.

Embodiment 3

[0054] On the basis of Embodiment 1, this embodiment provides an integrated desulfurization device that precisely controls the injection amount of desulfurization agent. The inner top of the gas-liquid separator 4 is provided with a mist-enhancing screen 13, and the gas-liquid separator 4 4 is installed with a liquid level gauge 1, and the liquid discharge port of the gas-liquid separator 4 is connected with a liquid discharge system 1 7, and the liquid discharge system 1 7 includes a pneumatic regulating valve 1 and a pneumatic shut-off valve 1, and the pneumatic regulating valve 1 Valve 1 and pneumatic shut-off valve 1 are sequentially arranged on the liquid discharge pipeline of the gas-liquid separator 4 along the liquid flow direction, and the liquid discharge pipeline is connected with a sewage system;

[0055] The drainage pipeline is connected with a sewage system;

[0056] The first liquid level gauge, the first pneumatic regulating valve and the first pneumatic cut-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com