Leather perforating device for assembly line

A punching device and assembly line technology, applied in leather punching/punching/cutting, raw hide/leather/fur manufacturing equipment, small raw hide/big raw hide/leather/fur treatment, etc., can solve difficult assembly line belt fast punching , heating power error and other issues, to achieve the effect of saving economic costs and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

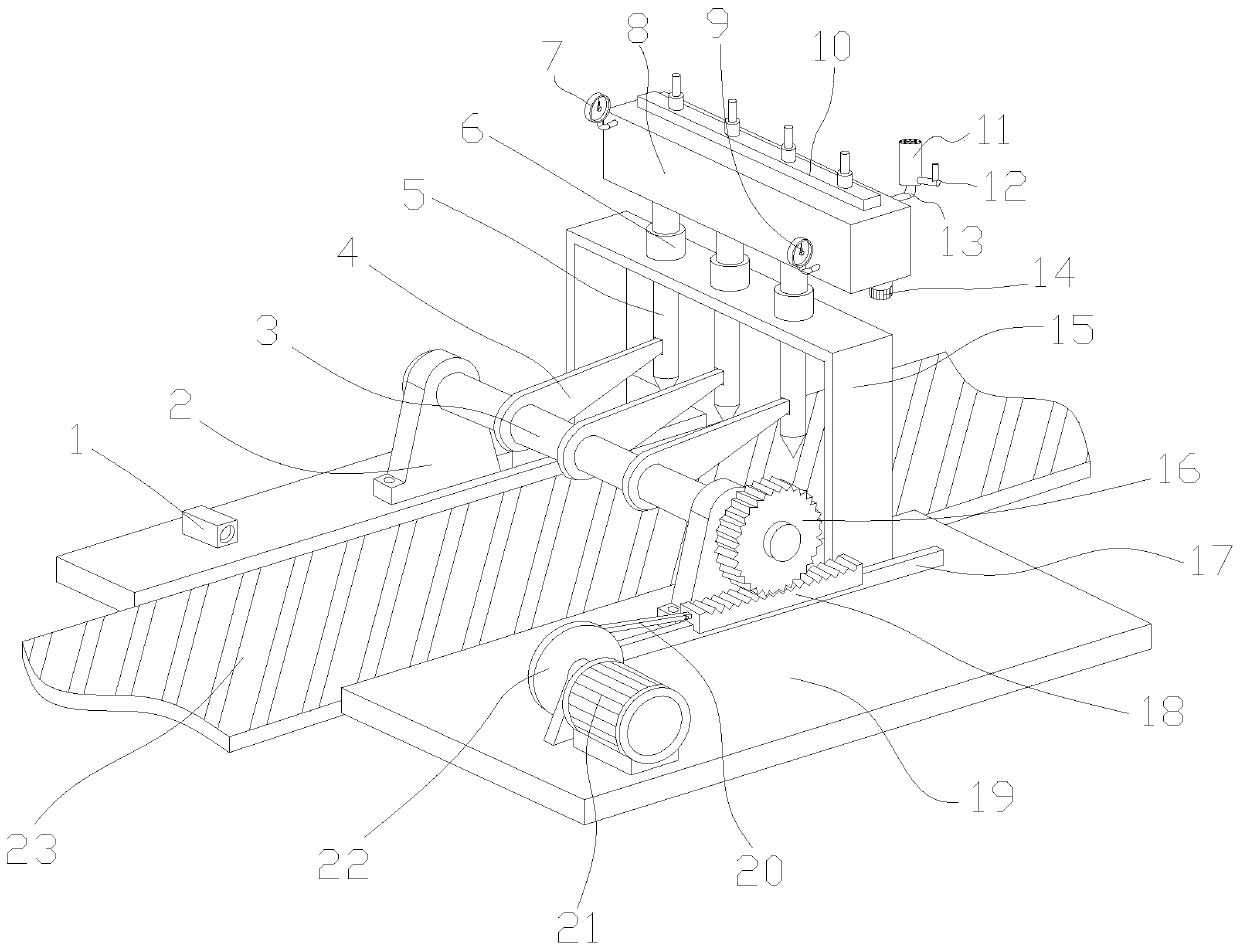

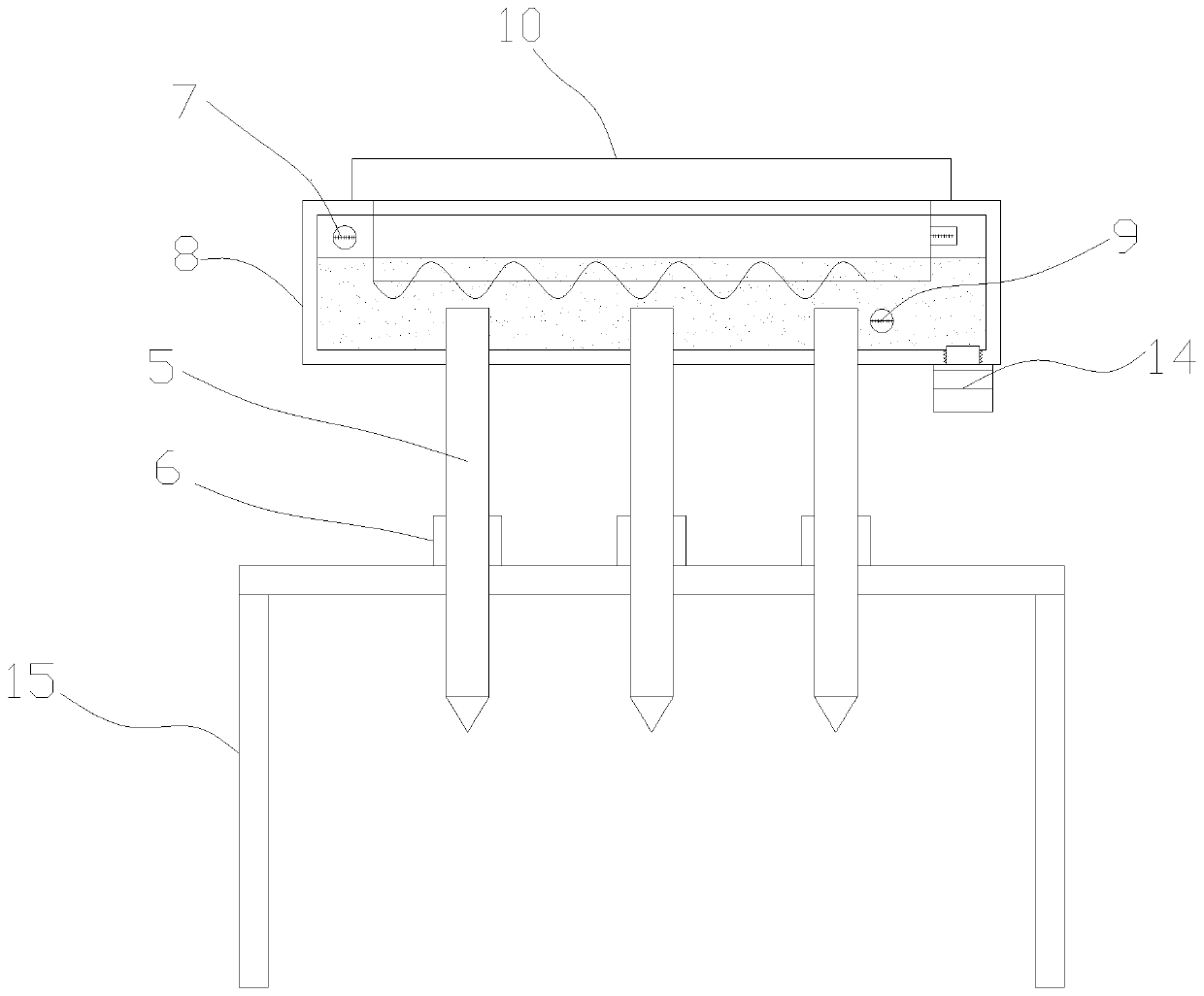

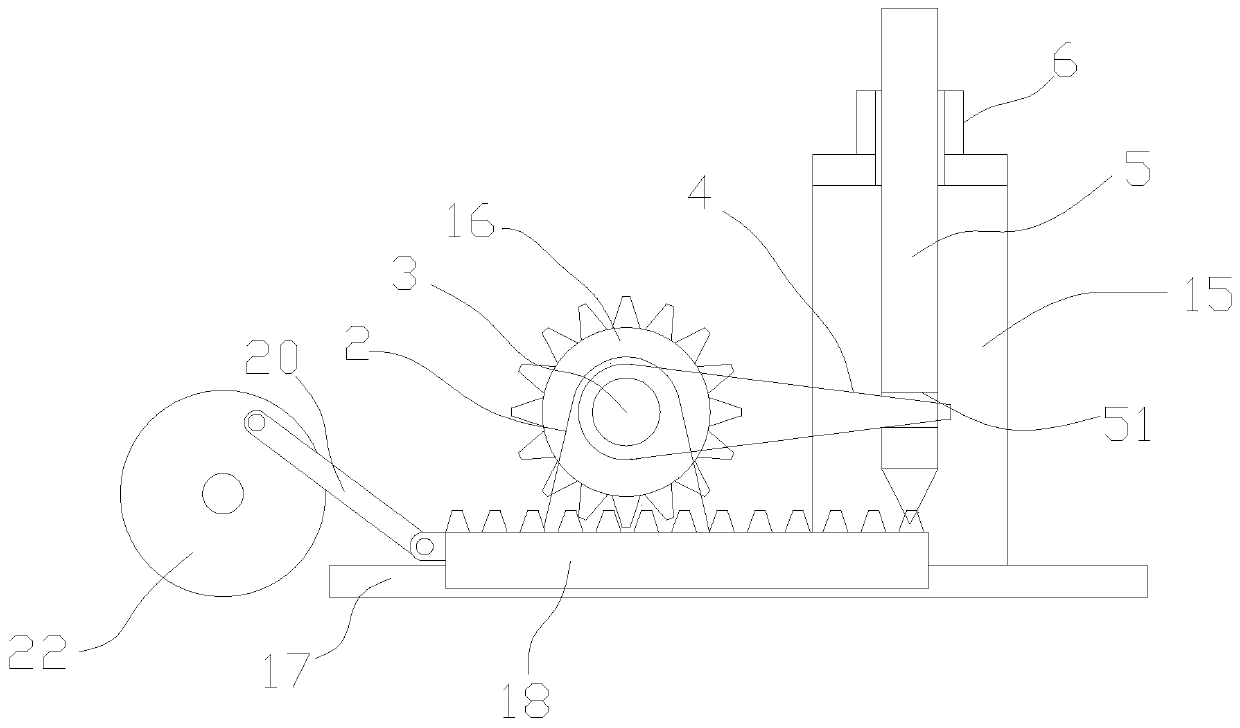

[0026] see Figure 1-Figure 5 , the present invention provides an assembly line leather punching device: it includes a sensor 1, a rotating shaft seat 2, a rotating shaft 3, a cam 4, a drill bit 5, a limit cylinder 6, a pressure gauge 7, a heating box 8, a thermometer 9, a heater 10. Filter device 11, handle 12, exhaust pipe 13, drain plug 14, frame 15, gear 16, slide rail 17, tooth row 18, base 19, connecting rod 20, motor 21, turntable 22, transmission belt 23 , the sensor 1 is located on one side of the transmission belt 23, the shaft seat 2 is installed on the base 19, the base 19 is provided with two, and the transmission belt 23 is located between the two bases 19, so The cam 4 and the drill bit 5 are all provided with several, the cam 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com