Catalyst chemical determination method for total hydrogen sulfide content in liquid sulfur

A technology of liquid sulfur and catalyst, which is applied in the direction of chemical analysis by catalysis, can solve the problems of unguaranteed accuracy, time-consuming and labor-intensive, etc., and achieves the effect of convenient operation and simple experimental device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

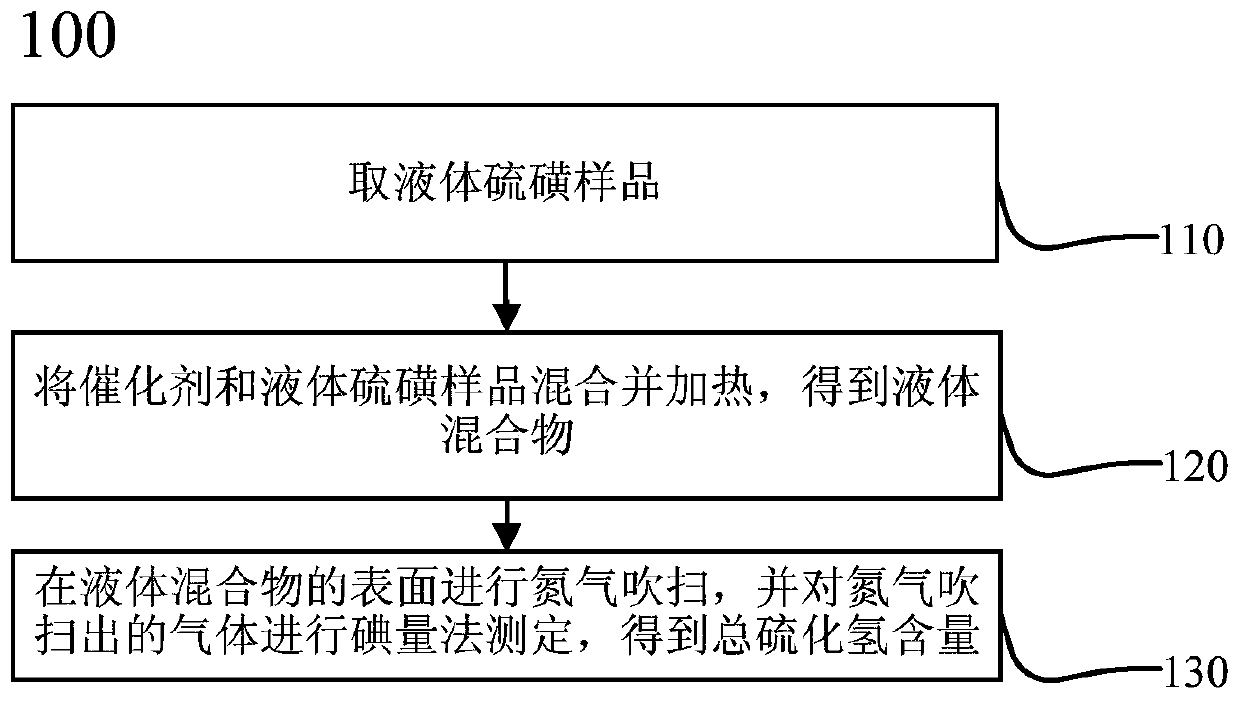

[0033] The present embodiment provides a catalyst chemical determination method 100 of total hydrogen sulfide content in liquid sulfur, such as figure 1 shown, including:

[0034] Step 110, taking a liquid sulfur sample.

[0035] Step 120, mixing and heating the catalyst and the liquid sulfur sample to obtain a liquid mixture.

[0036] Step 130, purging the surface of the liquid mixture with nitrogen, and performing iodometric measurement on the gas purged by nitrogen to obtain the total hydrogen sulfide content.

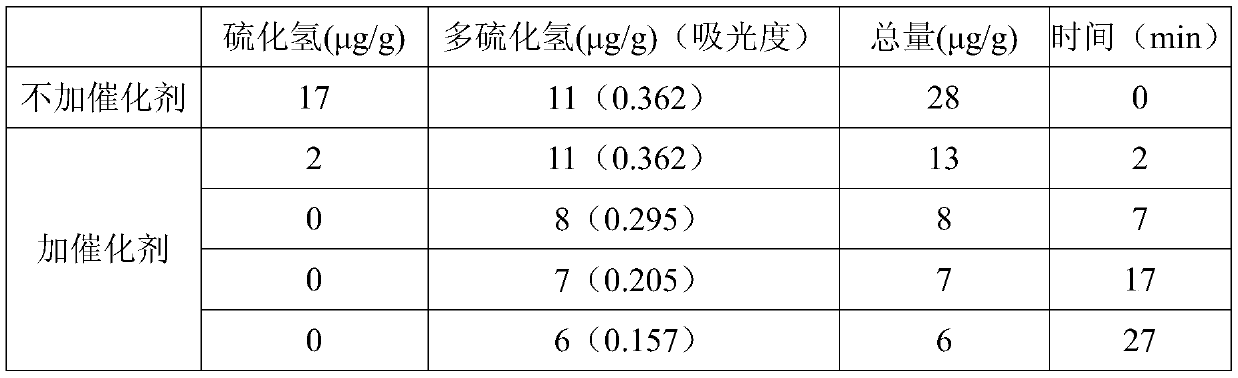

[0037] After testing, a certain proportion of catalyst was added to the liquid sulfur sample, and after nitrogen purging, the purged sample was taken to an infrared instrument for analysis, and it was found that the peaks of hydrogen sulfide and polyhydrogen sulfide in the infrared spectrum disappeared. The result is shown as zero (the data are shown in Table 1 below), so it can be known that the hydrogen sulfide and hydrogen polysulfide in the liquid sulfur are a...

Embodiment 2

[0044] The present embodiment provides a catalyst chemical determination method 100 of total hydrogen sulfide content in liquid sulfur, such as figure 1 shown, including:

[0045] Step 110, taking a liquid sulfur sample.

[0046] Step 120, mixing and heating the catalyst and the liquid sulfur sample to obtain a liquid mixture.

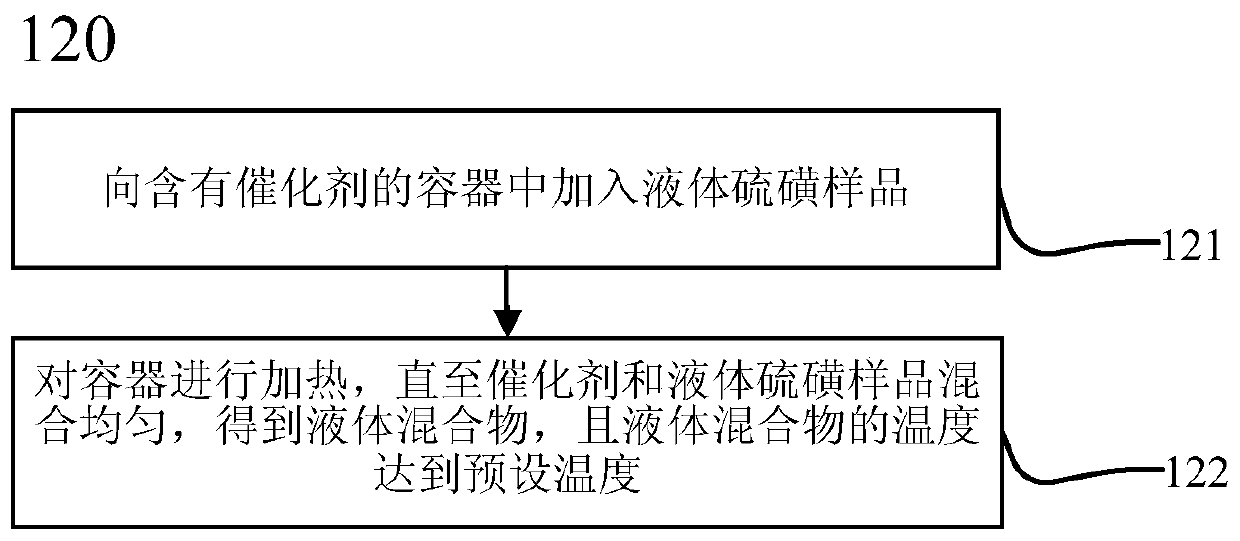

[0047] On the basis of Example 1, such as figure 2 As shown, step 120 specifically includes:

[0048] Step 121, adding liquid sulfur sample into the container containing the catalyst.

[0049] Step 122, heating the container until the catalyst and the liquid sulfur sample are evenly mixed to obtain a liquid mixture, and the temperature of the liquid mixture reaches a preset temperature.

[0050] Step 130, purging the surface of the liquid mixture with nitrogen, and performing iodometric measurement on the gas purged by nitrogen to obtain the total hydrogen sulfide content.

[0051] In this embodiment, the catalyst is placed at the bottom of the con...

Embodiment 3

[0053] The present embodiment provides a catalyst chemical determination method 100 of total hydrogen sulfide content in liquid sulfur, such as figure 1 shown, including:

[0054] Step 110, taking a liquid sulfur sample.

[0055] Step 120, mixing and heating the catalyst and the liquid sulfur sample to obtain a liquid mixture.

[0056] like figure 2 As shown, step 120 specifically includes:

[0057] Step 121, adding liquid sulfur sample into the container containing the catalyst.

[0058] Step 122, heating the container until the catalyst and the liquid sulfur sample are evenly mixed to obtain a liquid mixture, and the temperature of the liquid mixture reaches a preset temperature.

[0059] Step 130, purging the surface of the liquid mixture with nitrogen, and performing iodometric measurement on the gas purged by nitrogen to obtain the total hydrogen sulfide content.

[0060] On the basis of Example 2, the preset temperature above is the temperature of the mother liquor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com