a dimmer

A dimmer and optical path technology, applied in the field of dimmers, can solve the problems of inability to ensure long-term stable operation of the equipment, not meeting the moving target simulator, low transmittance of liquid crystal light valves, etc., to ensure long-term stable operation, The effect of high light efficiency utilization and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

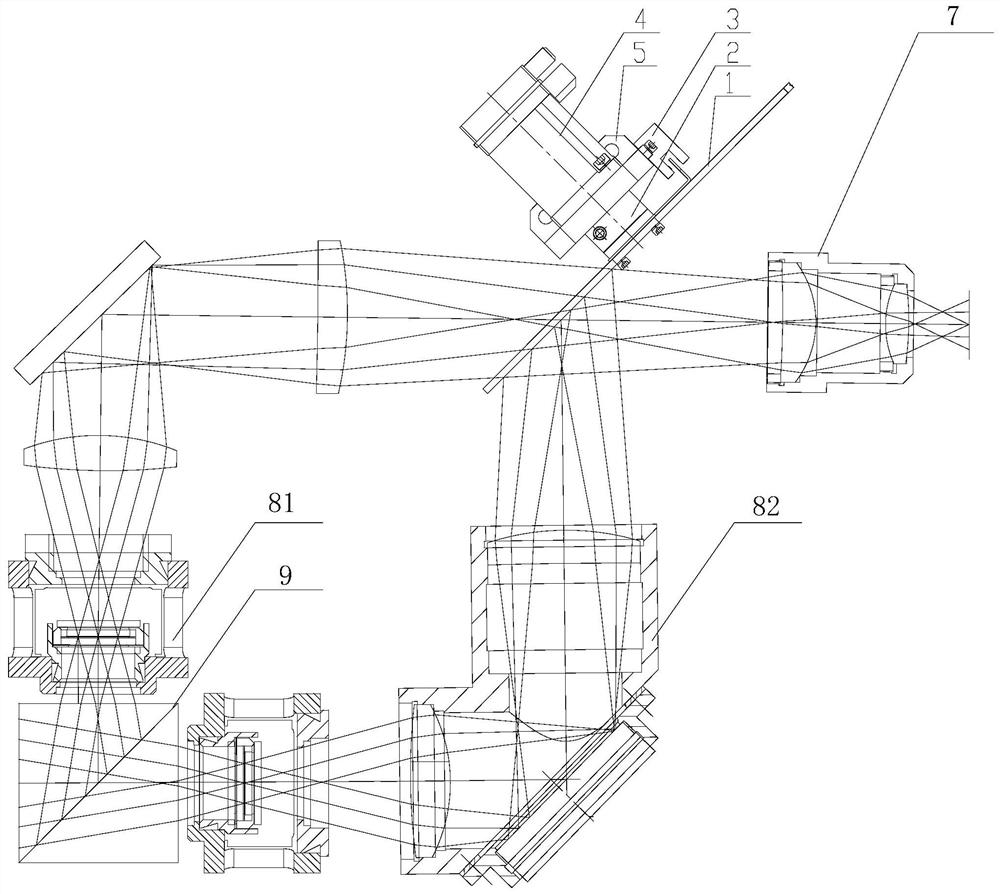

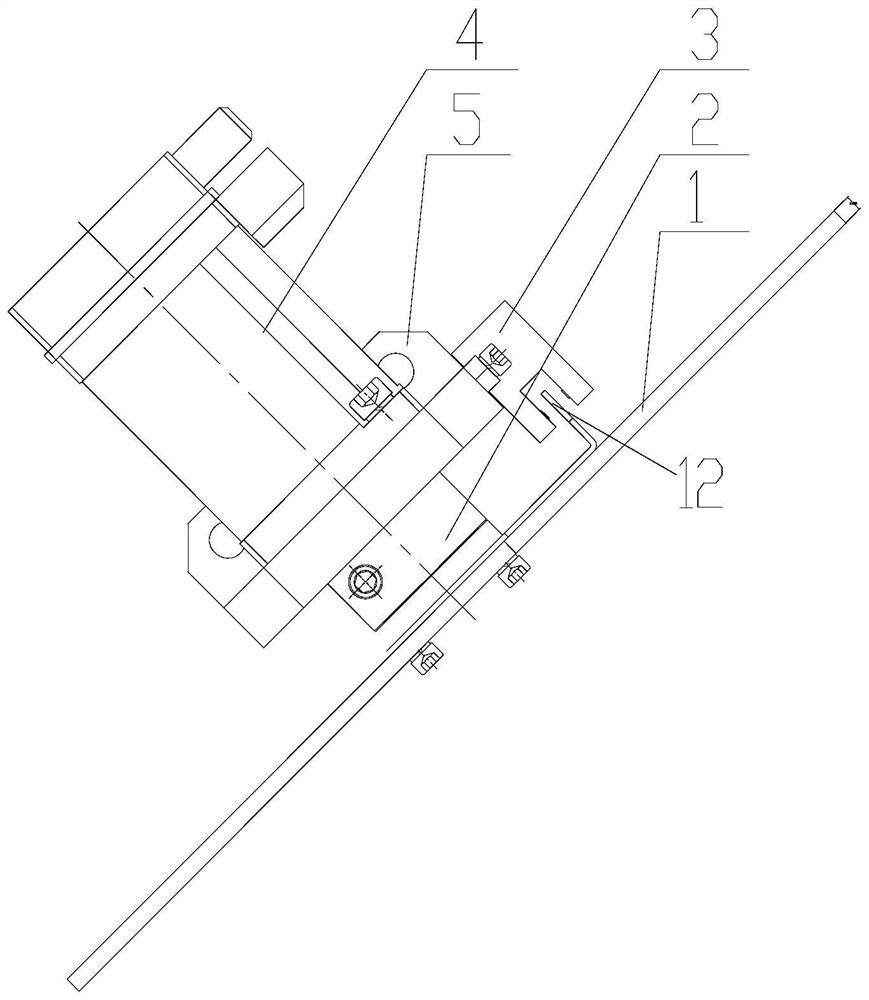

[0050] The structure of the dimmer in this embodiment is shown in FIG. 1 . Dimming disc 1 adopts the structure shown in Figure 2(a), and the size of the disc is designed according to the light-passing area. The disc is precisely processed by a diamond lathe, and has high surface precision and high reflectivity. The reflective optical path 82 works when 1 is cut into the optical path, and the transmissive optical path 81 works when the dimming disc 1 is cut out of the optical path. The disc 1 is connected to the servo motor 3 through the motor coupling 2, and the motor rotates once so that the reflected optical path 82 and the transmitted optical path 81 can work twice respectively, so setting the rotation frequency of the disc 1 to 50 Hz can achieve a frame frequency of 200 Hz. The servo motor 3 is used to drive the rotation frequency of 50 Hz corresponding to a speed of 3000 rpm, which is within the rated speed range of the servo motor 3 and can work for a long time. The pho...

Embodiment 2

[0053] On the basis of the hardware of Embodiment 1, the present embodiment further includes installing a digital I / O card, an analog DA card and an encoder card on the PCI bus of the control computer, for realizing the sampling and output of the control signal: wherein the digital The quantity I / O card receives the external synchronous signal and the pulse level of the feedback signal of the photoelectric switch, the analog quantity DA card can output the analog quantity voltage signal of -10V~+10V, the motor driver receives the analog quantity voltage signal and drives the motor at -3500rpm / The speed is regulated within the range of 1-3500 rpm, and a certain margin of speed regulation can be left to avoid synchronization failure caused by the frequency jitter of the input signal; the servo motor itself is equipped with an encoder, and the encoder card can detect the encoder feedback. Obtaining the position information of the current dimmer, one imaging device can meet the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com