Silica gel scar plaster and preparation method thereof

A technology of silicone gel and scar, applied in the field of medical dressing and its preparation, can solve the problems of increasing use cost, waste of resources and the like, and achieve the effects of improving breaking strength, saving resources and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

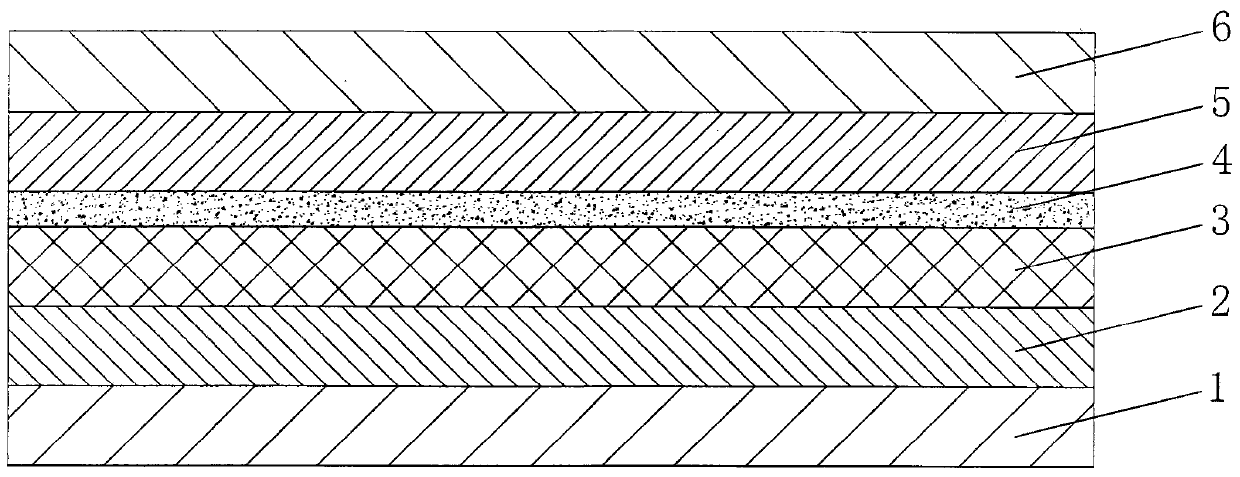

[0025] A) Prepare the glue-coated base layer. First, corona treatment is carried out on the side surface of the backing layer 1 towards the medical adhesive layer 2. The corona voltage of the corona treatment is 10000V. During the corona treatment, the surface of the backing layer 1 Advance speed control is 10m / min, obtains the backing film of corona treatment, in this step, the backing film of aforementioned corona treatment is the polyurethane film that thickness is 1.0mm, then the grammage is 40g / m 2 The pressure-sensitive adhesive used as the medical adhesive layer 2 is coated on one side surface of the aforementioned corona-treated polyurethane film and heated and cured at 50°C to obtain the glue-coated base layer. The pressure-sensitive adhesive described in this step is polyethylene base ether glue;

[0026] B) prepare the composite body, first to the side of the transition layer 3 facing away from the medical adhesive layer 2 that is facing upwards (with figure 1 The ...

Embodiment 2

[0030] A) Prepare the glue-coated base layer. First, corona treatment is carried out on the side surface of the backing layer 1 towards the medical adhesive layer 2. The corona voltage of the corona treatment is 14500V. During the corona treatment, the surface of the backing layer 1 Advance speed control is 30m / min, obtains the backing film of corona treatment, in this step, the backing film of aforementioned corona treatment is the polyethylene film that thickness is 0.01mm, then the grammage is 10g / m 2 The pressure-sensitive adhesive used as the medical adhesive layer 2 is coated on one side surface of the aforementioned corona-treated polyethylene film and heated and cured at 50°C to obtain the glue-coated base layer. The pressure-sensitive adhesive described in this step is polyurethane glue;

[0031] B) prepare the composite body, first to the side of the transition layer 3 facing away from the medical adhesive layer 2 that is facing upwards (with figure 1 The shown posi...

Embodiment 3

[0035] A) Prepare the glue-coated base layer. First, corona treatment is carried out on the side surface of the backing layer 1 towards the medical adhesive layer 2. The corona voltage of the corona treatment is 16000V. During the corona treatment, the surface of the backing layer 1 Advance speed control is 60m / min, obtains the backing film of corona treatment, in this step, the backing film of aforementioned corona treatment is the polyester film that thickness is 0.1mm, then the grammage is 100g / m 2 The pressure-sensitive adhesive used as the medical adhesive layer 2 is coated on one side surface of the aforementioned corona-treated polyester film and heated and cured at 100°C to obtain the glue-coated base layer. The pressure-sensitive adhesive described in this step is a natural rubber;

[0036] B) prepare the composite body, first to the side of the transition layer 3 facing away from the medical adhesive layer 2 that is facing upwards (with figure 1 The shown position s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com