Heat-sensitive microcapsule color development material and preparation method thereof

A microcapsule, heat-sensitive technology, applied in reproduction/marking method, temperature recording method, printing and other directions, can solve the problems of low color density, affecting the application in the field of medical recording, unable to meet the requirements of medical recording materials, etc. High, conducive to industrialization, excellent black effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

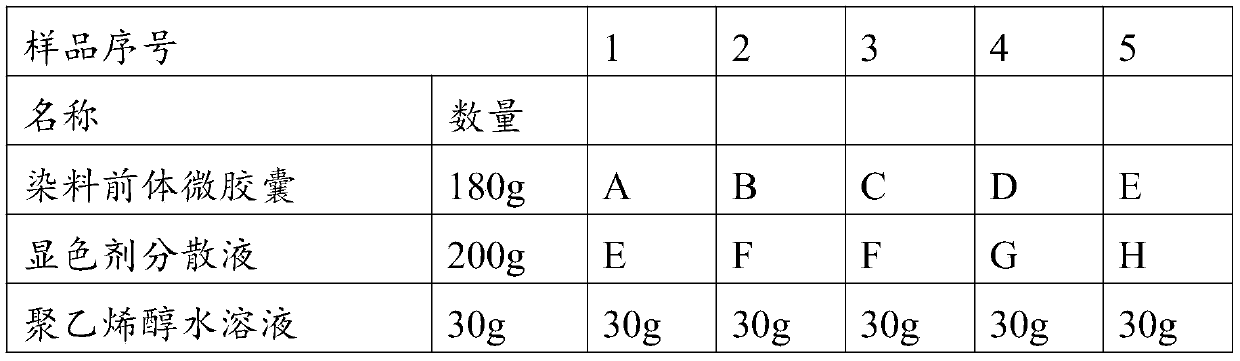

Examples

preparation example Construction

[0050] The present invention also provides a preparation method of sensitive microcapsule chromogenic material, specifically comprising the following steps:

[0051] S1 Preparation of Dye Precursor Microcapsules

[0052] S11 Weigh the dye precursor, cyclohexanone and ethyl acetate according to the above-mentioned heat-sensitive microcapsule coloring material, mix and stir, and heat to 70-90°C to dissolve to obtain a dye mixture;

[0053] S12 Cool the dye mixture to 15-30°C, add xylylene diisocyanate and stir to obtain an oil phase mixture; the mass ratio of dye mixture to xylylene diisocyanate is (3-20):1, stir The rotating speed is 300~1200rpm, and the time is 1~5min;

[0054] S13 Add a surfactant to the polyvinyl alcohol aqueous solution and stir to obtain an aqueous phase mixture; wherein the concentration of the polyvinyl alcohol aqueous solution is 2 to 10%, the degree of alcoholysis is 88%, and the average degree of polymerization is 2245. The polyvinyl alcohol aqueous ...

Embodiment 1

[0062] The preparation method of dye precursor microcapsule A specifically comprises the steps:

[0063] Add 15g of S205, 5g of ODB-2, 10g of RED-3, 5g of GN-2, 2g of ethyl acetoacetate and 160g of ethyl acetate into a 300ml beaker, stir, heat to dissolve, and when cooled to room temperature, add 80g of D110-N, stirred to obtain an oil phase mixture.

[0064] In a 1000ml container, add 400g of polyvinyl alcohol aqueous solution with a concentration of 5%, an alcoholysis degree of 88%, and an average polymerization degree of 2245, and add 40g of OP10 and stir to obtain an aqueous phase.

[0065] The oil phase mixture obtained above was slowly added to the water phase solution, and dispersed at a speed of 6000 rpm for 15 min using high-speed shear stirring to obtain an oil emulsion dispersion with an average particle size of 0.8 μm. Adding 400g of polyvinyl alcohol aqueous solution with a concentration of 3% and an alcoholysis degree of 88% and an average degree of polymerizati...

Embodiment 2

[0067] The preparation method of dye precursor microcapsule B specifically comprises the steps:

[0068] Add 16g of S205, 4g of ODB-2, 10g of RED-3, 5g of GN-2, 4g of ethyl acetoacetate and 130g of ethyl acetate into a 300ml beaker, stir, heat to dissolve, when cooled to room temperature, add 80g of D110-N, stirred to obtain an oil phase mixture.

[0069] In a 1000ml container, add 400g of polyvinyl alcohol aqueous solution with a concentration of 5%, an alcoholysis degree of 88%, and an average polymerization degree of 2245, and add 40g of OP10 and stir to obtain an aqueous phase.

[0070] The oil phase mixture obtained above was slowly added to the water phase solution, and dispersed at a speed of 6000 rpm for 15 min using high-speed shear stirring to obtain an oil emulsion dispersion with an average particle size of 0.8 μm. Adding 400g of polyvinyl alcohol aqueous solution with a concentration of 3% and an alcoholysis degree of 88% and an average degree of polymerization o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com