A crystallization system and method for enhancing the molecular crystallization process

A molecular crystallization and crystallization technology, applied in the direction of solution crystallization, crystallization adjustment/control, etc., can solve the problems of difficult to achieve supersaturation of crystallization solution concentration, limit the success rate of molecular crystallization, etc., to shorten the induction time, precise and controllable crystallization process, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

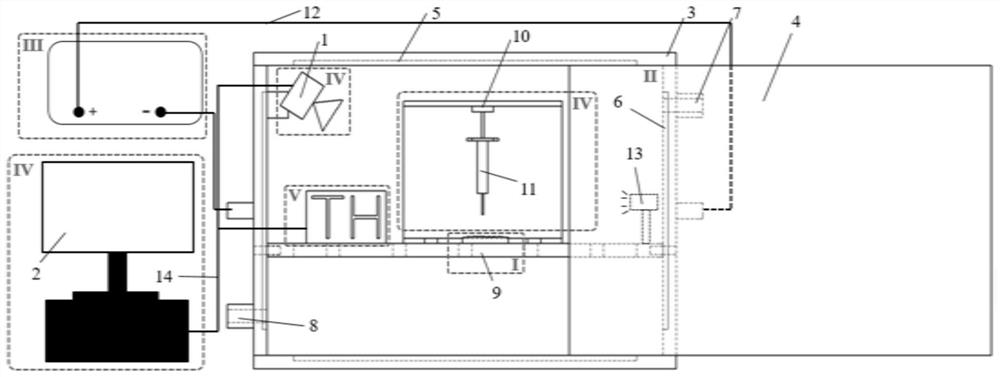

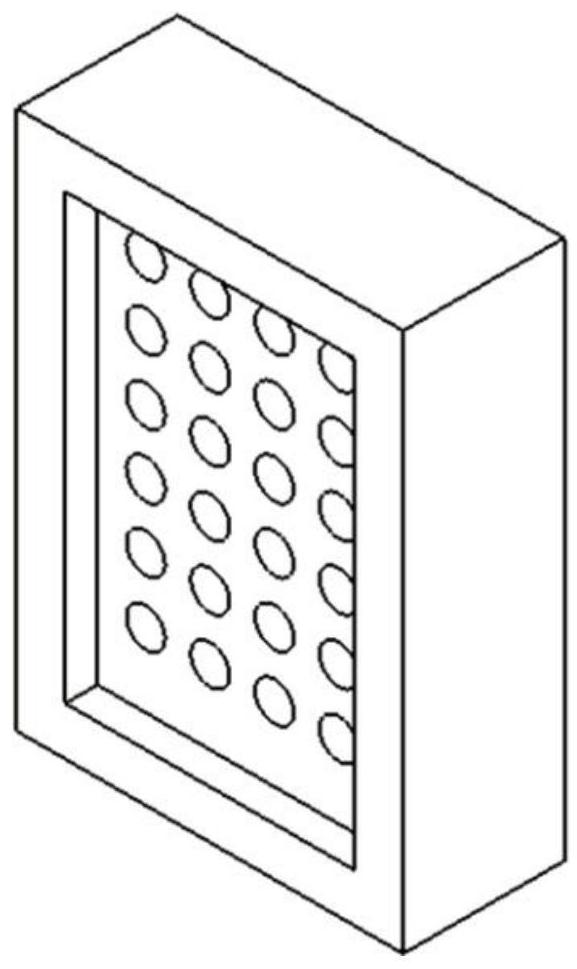

Method used

Image

Examples

Embodiment 1

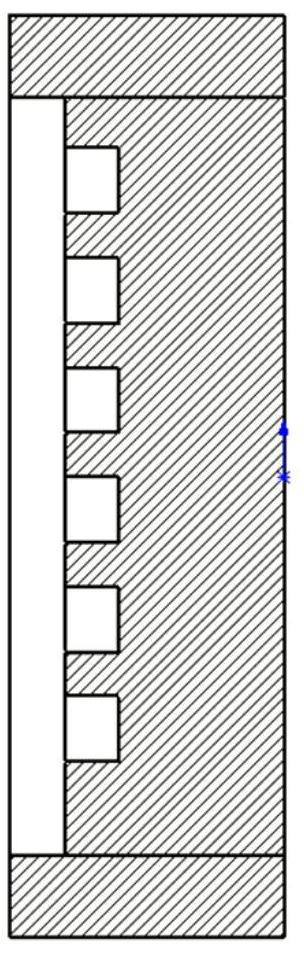

[0030] Prepare the micro crystallizer by 3D printing technology, and use the method a in step 1 to process the crystallizer for use. Dissolve 1.4g of NaCl in 20mL of deionized water, and prepare a stable and uniform solution at 25°C for use. Open the nitrogen inlet and outlet valves, exhaust the air in the crystallization system, and use the temperature and humidity controller to regulate the temperature in the system to 10-30°C and the humidity to 40-80%. Then use the droplet adding device to drop the configured crystallization solution in the charged concave well matrix of the microcrystallizer, and immediately turn on the high-voltage direct current power supply (connect the upper and lower electrode plates), adjust the voltage to 10kV, and make the crystallizer Static evaporation in a stable electric field for 24h, to obtain crystals such as image 3 .

Embodiment 2

[0032]Prepare the micro crystallizer by 3D printing technology, and use the method c in step 1 to process the crystallizer for use. Dissolve 13.6g of sodium acetate powder in 83.1g of glacial acetic acid solution to make acetic acid-sodium acetate buffer concentrate, take 6.5g of acetic acid-sodium acetate buffer concentrate and dissolve it in 1L of deionized water, stir well to obtain a pH value of 3.65 buffer for use. Subsequently, dissolve 300mg of lysozyme freeze-dried powder in 10mL of the above buffer, dissolve 0.5g of NaCl in 10mL of buffer as a crystallization agent, mix the two, add 0.6g of glycerol as an additive, and mix well Afterwards, the lysozyme solution was obtained for use. Open the nitrogen inlet and outlet valves, exhaust the air in the crystallization system, and use the temperature and humidity controller to regulate the temperature in the system to 10-30°C and the humidity to 40-80%. Then drop the above-mentioned crystallization solution into the charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com