Unitized self-replacement type efficient waste gas filtering device

A high-efficiency filtration and waste gas filtration technology, which is applied in the direction of dispersed particle filtration, transportation and packaging, chemical instruments and methods, etc., can solve the problems of consuming a lot of manpower, material and financial resources, reducing the continuity and high speed of waste gas filtration, and troublesome cleaning. To achieve the effect of self-replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

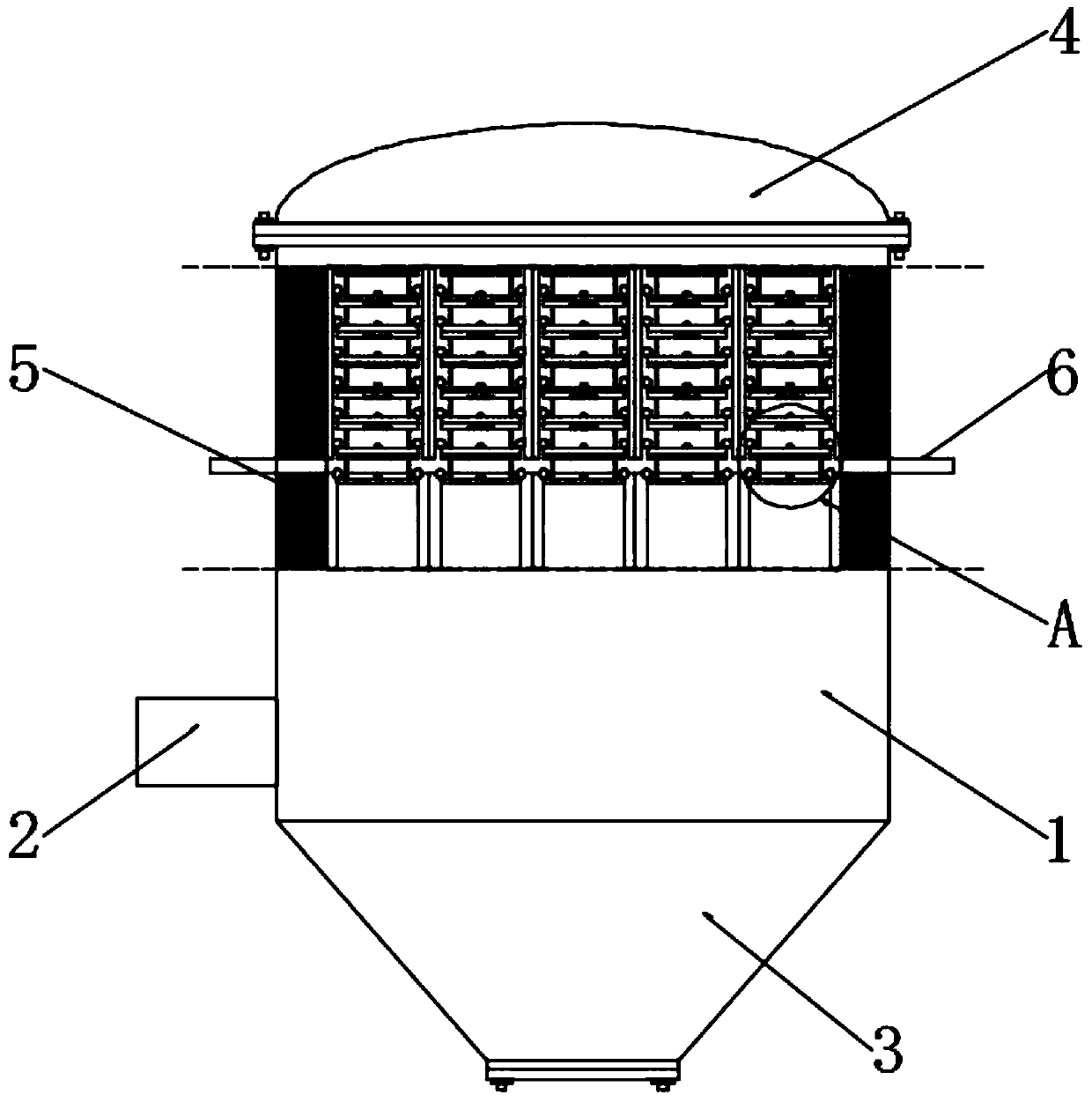

[0044] see figure 1 , a unitized self-replacement waste gas high-efficiency filter device, including a waste gas filter tower 1, an air inlet pipe 2 is fixedly installed at one end of the waste gas filter tower 1, and an inspection cover 4 and a discharge port 3 are respectively installed at the upper and lower ends of the waste gas filter tower 1, The exhaust gas filter tower 1 is fixedly installed with a plurality of splitter tubes 5 connected to each other. The upper end of the splitter tube 5 is provided with a plurality of vertically distributed unit filter layers. The lowermost unit filter layer plays a role in filtering exhaust gas. The upper side The unit filter layers all play the role of supplementary replacement.

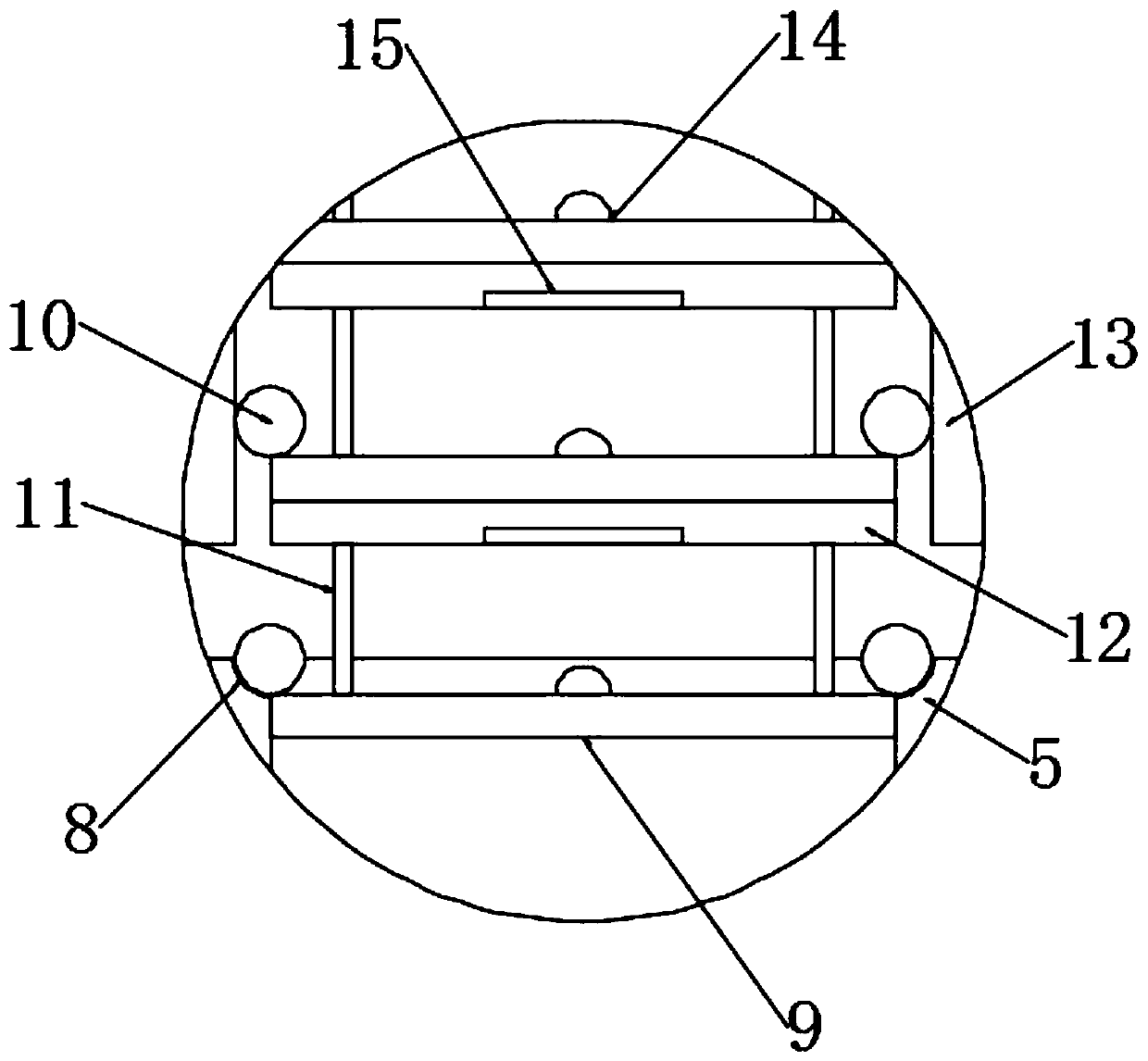

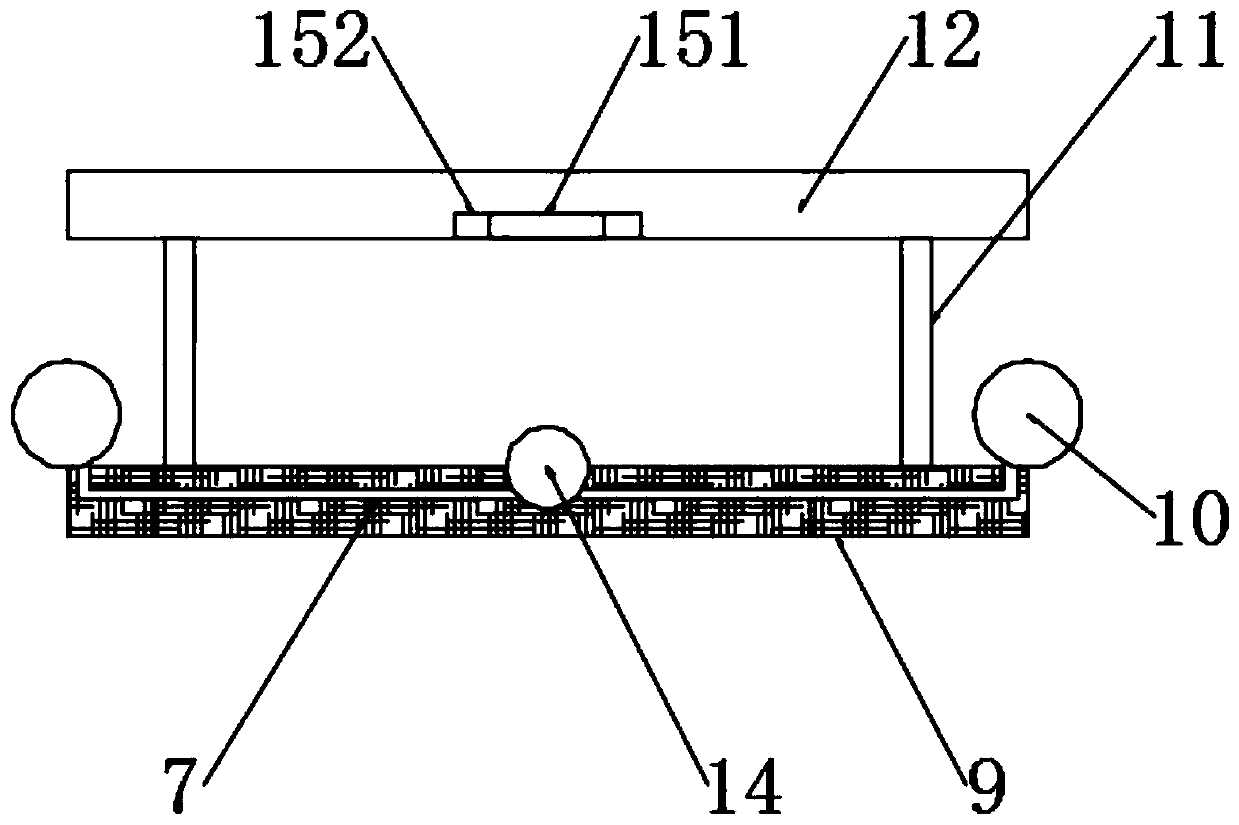

[0045] see Figure 2-3 , the unit filter layer includes a fiber filter layer 9, a plurality of bisexual snap balls 10 distributed in an annular array are fixedly connected to the edge of the upper end of the fiber filter layer 9, and a plurality of bisex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com