Novel environment-friendly pulverized coal processing and grinding equipment

A pulverized coal, environmental protection technology, applied in the field of new environmentally friendly pulverized coal processing and grinding equipment, can solve the problems of high manufacturing costs, achieve the effects of improving efficiency, improving quality, and facilitating screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

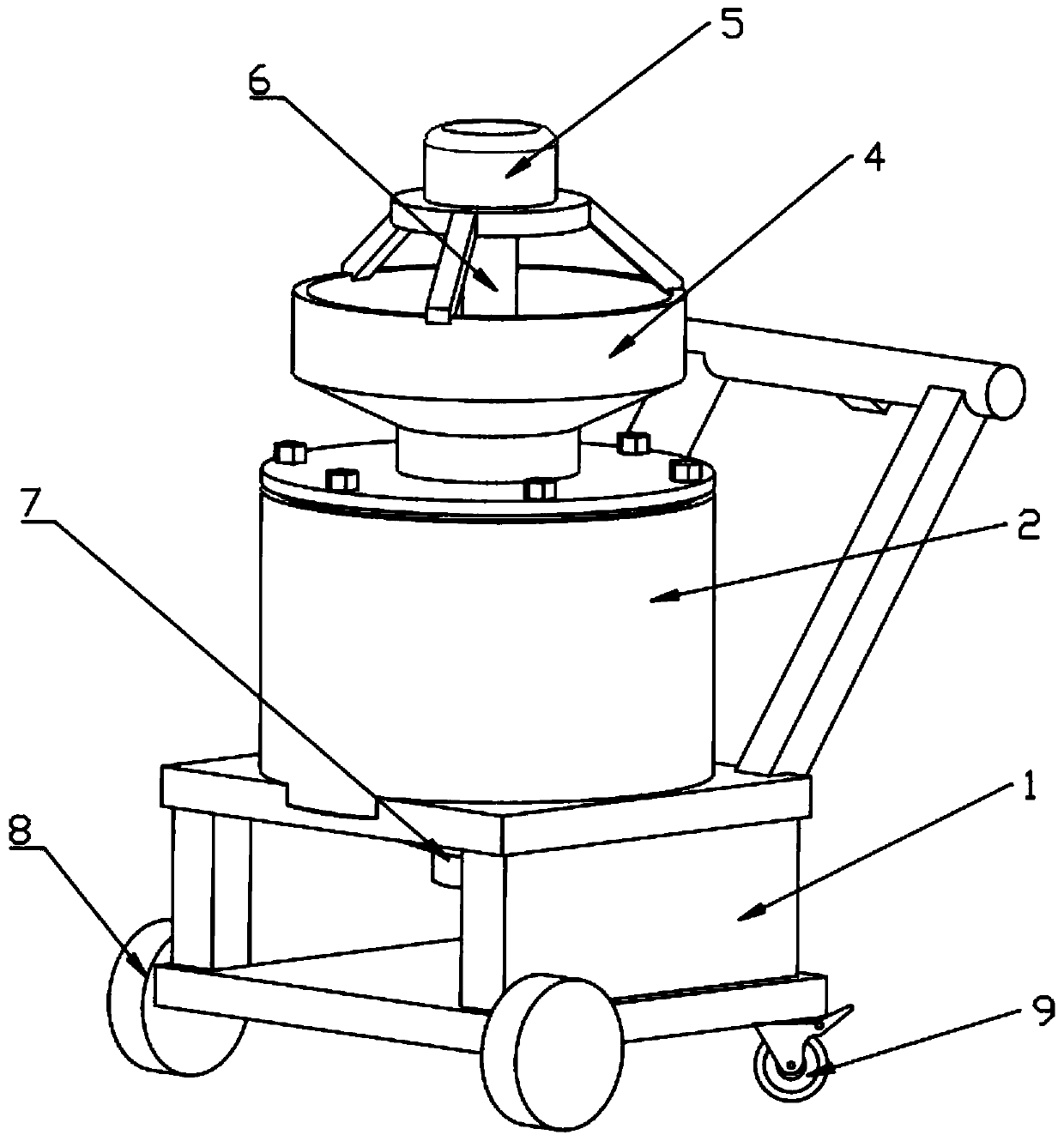

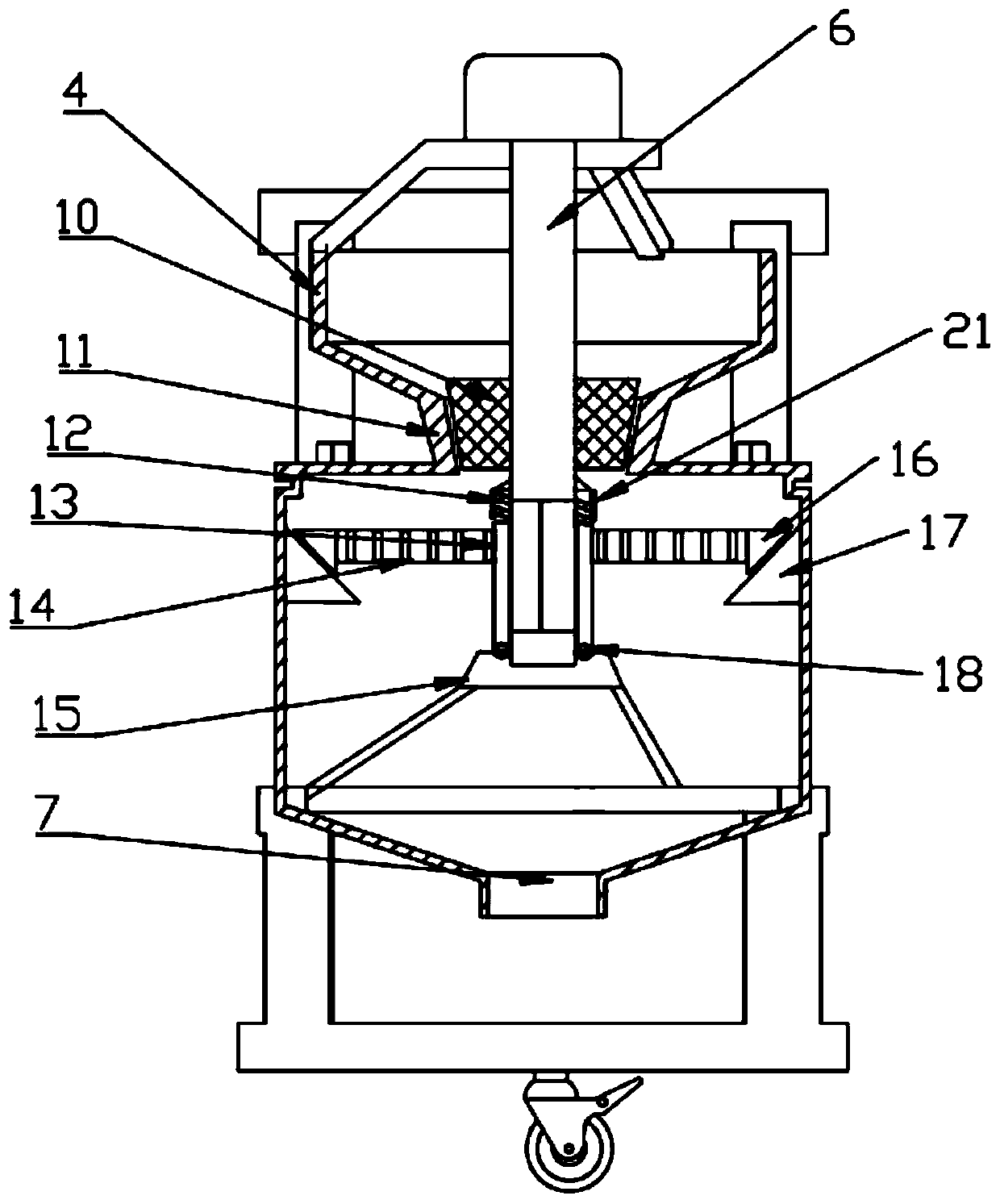

[0030] see Figure 1-3 , a new type of environmentally friendly pulverized coal processing and grinding equipment, the pulverized coal processing and grinding equipment includes:

[0031] A base 1, on which a cylinder 2 is fixedly installed;

[0032] The feed hopper 4 is fixedly connected to the top center of the cylinder body 2;

[0033] The driving part is installed on the upper center of the feed hopper 4 through the connecting rod;

[0034] The rotating shaft 6 is arranged inside the feeding hopper 4 and the barrel 2 for the penetrating rotation, and is coaxially fixed with the output shaft of the driving member;

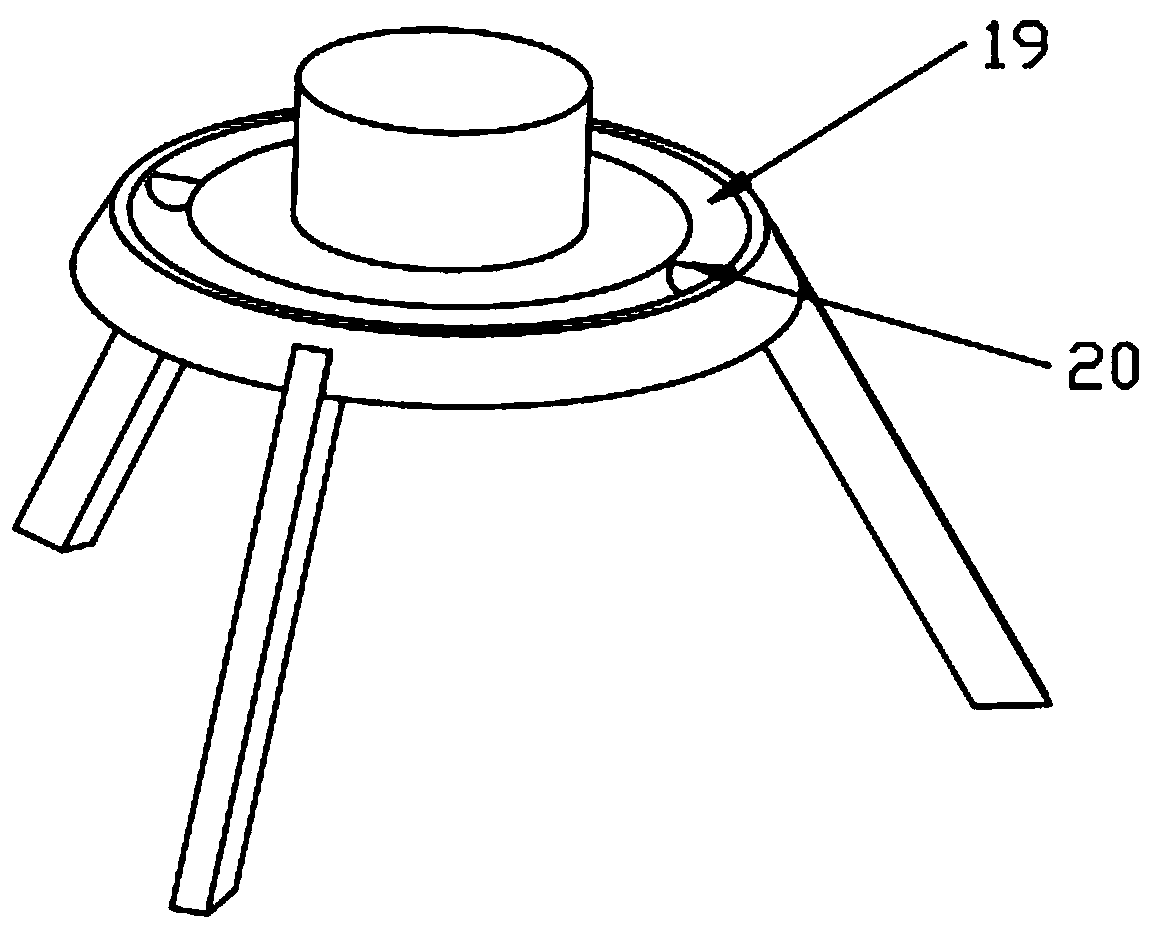

[0035] Wherein, a feed hopper 4 is connected to the center of the top of the cylinder body 2, and the inside of the feed hopper 4 holds raw materials to be ground. The driving member can be a motor 5 , a fuel engine or other driving devices. The inner bottom of the barrel 2 is fixedly provided with a support frame 15 , and the bottom of the rotating shaft 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com